Home > About Us > Corporate Social Responsibility > Sustainability Report > Sustainability Report 2006 > Environmentally Friendly Manufacturing (4) Reduction of Environmental Burdens

| Environmental Management Sustainability Report 2006 |

|||

| Environmentally Friendly Manufacturing (4) Reduction of Environmental Burdens |

Based on the analysis results of various environmental burdens, Kobe Steel has been reducing a wide variety of burdens by improving production processes to more effectively protect the environment; introducing state-of-the-art equipment and refurbishing facilities; and thoroughly implementing self-management. Kobe Steel, including its group companies, is further striving to reduce its impact on the environment by improving its production processes and enhancing the capabilities of pollution control equipment. |

| Air Pollution Prevention |

| Activities at works and plants | |

SOx (sulfur oxide) emission generated in production processes is controlled through energy conservation, desulfurization and other means, as well as implementing waste gas measures. At the steelworks, the volume of waste emissions has gone down through the use of low-sulfur iron ore, the adoption of city gas, and the desulfurization of coke oven gas and boiler waste gas. With respect to NOx (nitrogen oxide), Kobe Steel promotes emission reduction by adopting low NOx burners and low NOx combustion technologies, introducing NOx removal equipment, and implementing energy-saving measures to reduce the emission volume. In the future, renovation and remodeling of facilities is planned as a countermeasure to air pollution. We are also working to prevent any deviation from emission standards through continuous recording of environmental data and tighter control of operations. Despite efforts to prevent dust scattering through the use of remote-controlled water spraying at the raw materials yard and by the sealing of equipment, complaints about dust from residents living close to the works remain at the same level. We therefore regard dust control as a serious and urgent issue, and we are taking more drastic measures, such as installing dust-control netting, building confining walls round recycling zones, sealing belt conveyors and incineration ash storage areas, and boosting the capacity of dust collecting and water spraying equipment. |

SOx Emissions (parent company only) |

NOx Emissions (parent company only) |

| * | Data for fiscal years 1990, 1995 and 2000 include emissions from Kakogawa and Kobe works. |

| * | SOx and NOx emissions from fiscal 2001 to 2005 were recalculated due to the discovery that air emissions had exceeded the statutory limit, data had been inappropriately handled, and other problems. Compared to total emissions, SOx had increased a maximum of 1.3% and NOx had increased a maximum of 1.3%. |

|

|||||||

| Environmental Activities in Group Companies | |

Shinko Kobe Power Inc. has a generation capacity of 1.4 million kilowatts of electricity after the second power plant started operation in April 2004. It is an urban power station that coexists in harmony with the community. On this theme, tough environmental conservation measures are taken -- including water quality conservation, noise, vibration, and offensive odor prevention, measures against wastes, and environmental harmony -- by installing cutting-edge environmental analysis equipment and optimizing the environmental management system through ISO14001. For these environmental measures, about one third of the total construction cost of the power station (about 200 billion yen) was allocated. Furthermore, part of the existing facilities in Kobe Works, such as the raw materials yard and sintering plant, were shut down, while the fuel for steelmaking facilities was changed from heavy oil to city gas. These comprehensive environmental measures by Kobe Works have made it possible to keep the impact on the surrounding environment to a minimum. |

| Shinko Kobe Power Inc. | ||

|

||

|

Continuous enclosed coalunloader By enclosing theunloader, dust is prevented from scattering. |

Coal silo and enclosed belt conveyor Twelve silos that can store 30,000 tons of coal per silo are installed. By enclosed the belt conveyor, the coal is completely enclosed from quay to boiler. |

| State-of-the-art exhaust treatment equipment | |||||

|

| Water Pollution Prevention |

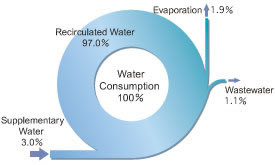

| Kobe Steel reduces the water consumption rate by improving production processes and using recycled water, and at the same time, cleans wastewater by an optimum wastewater treatment system and reduces the impact of water polluting substances such as COD (chemical oxygen demand) and SS (suspended solids) in public water bodies. Kobe Steel uses the water treatment system best suited to the properties of the discharged water from production processes. Other measures are also undertaken to improve water quality. For example, a water recycling system used at the steelworks purifies waste water from the various production processes and other effluent through a treatment system that combines coagulating sedimentation, sand filtration, membrane treatment, and biological treatment, for reuse on site. At the Kakogawa Works about 97% of the water is recycled. At the Welding Company's Saijo Plant, supplementary water for cooling the production line is recirculated. By improving the water route, the quantity of supplementary water was reduced by half. Also, Shinko Kobe Power Inc. discharges wastewater after thorough cleaning at a comprehensive water treatment plant that provides not only coagulating sedimentation, filtration and neutralization, but also advanced wastewater treatments such as denitrification and COD absorption. Shinko Kobe Power also uses an eco-friendly water-intake/discharge system. |

Wastewater Reduction Efforts at Kakogawa Works  Activated sludge treatment facility |

|

|

|||||||

| Noise Reduction |

| Kobe Steel carries out surveys on how plant noise affects the neighboring areas and reduces the noise of the equipment based on the survey data. In addition, Kobe Steel is implementing a wide variety of noise reduction measures by installing noise-generating equipment such as fans, compressors and crushers within buildings and by installing soundproof walls and vibration proof pads to shield and absorb noise. |

Sound suppressing equipment for exhaust stack  Sound suppressing cover for compressor |

| Odor Reduction |

Odors generated at works and plants are treated using deodorizing equipment. Odor monitoring is implemented at regular intervals and necessary measures are taken accordingly. |

| Soil Contamination |

We are working to stop soil contamination through strict observance of regulations, including the Soil Contamination Countermeasures Law, and through proper management of hazardous substances at plants. A study is carried out when selling land where former plants were situated. For example, in March 1996 the land of the former Amagasaki Steel Works was sold to Hyogo Prefecture. However, in keeping up with current laws, a soil study was subsequently carried out last year and additional steps were taken to stop the spread of contamination. |