Home > Products > Copper Sheet and Strip > Higher Stress Relaxation Resistance Copper Alloy CAC™ 5

Higher Stress Relaxation Resistance Copper Alloy CAC™ 5

Higher Stress Relaxation Resistance Copper Alloy CAC™ 5

CDA No. 19040

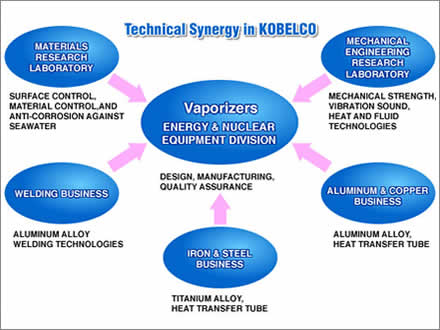

Good Points

![]()

- Is the copper alloy which optimized the characteristic for terminals with a wire barrel.

- Has excellent stress relaxation resistance and is suitable for the automotive application.

Is the copper alloy based on JASO-C400 class. - Has good strength and equipment of phosphorous bronze (C5210) or brass (C2600).

- Has the lineup with some pre-tin plating products. Has the plating types of New Tin Reflow and normal tin reflow.

Nominal Compositions

![]()

Cu-0.8Ni-1.2Sn-0.07P (mass%)

Characteristics

![]()

1. Physical Properties

| Specific Gravity | 8.9 |

|---|---|

| Coefficient of Thermal Expansion (293~573K) | 17.7 x 10-6/K Thermal |

| Conductivity (293K) | 166 W/m.K |

| Electrical Resistivity (293K) | 43.1 nΩ.m |

| Electrical Conductivity (293K) | 40 %IACS |

| Modulus Elasticity (293K) | 130 GPa |

* The above are typical characteristics.

2. Mechanical Properties

|

Temper |

Tensile Strength MPa |

Yield Strength MPa |

Elongation % |

Vickers Hardness MHv: 4.9N |

|---|---|---|---|---|

| H/SP | 500~590 | 530 | 7 min | 155~185 |

| EH/SP | 540~630 | 570 | 5 min | 165~200 |

* Yield strength are nominal values.

* The above tensile strength and hardness are our standard specifications.

We will adjust these specifications by your requests.

3. 90°W-type Bend-formability (MBR)

| Temper | Good Way | Bad Way |

|---|---|---|

| H/SP | 0 | 0 |

| EH/SP | 0.2 | 0.2 |

* The above are typical characteristics.

The value slightly varies depending on the thickness of specimens.

Use

![]()

Terminals and connectors for Automotive wire harness, Terminals and connectors for Consumers, Leadframe for mini-mold type transistor etc.

Others

![]()

Not used cadmium (Cd), lead (Pb), mercury (Hg), six value chrome (Cr+6), polybrominated biphenyl (PBB), Polybrominated biphenyl ether (PBDE) restricted with RoHS etc.

![]()

Kobe Steel, Ltd. Advanced Materials Business

Copper Rolled Products Unit

Copper Flat Rolled Products Sales Department