Home > Products > Ultra High Pressure Equipment > Technologies and Applications > High Pressure Food Processing (HPP)

High Pressure Food Processing (HPP)

High Pressure Food Processing (HPP)

Research and development of high pressure technology has been making rapid progress in food industry, aiming for its commercialization. Starting with jam, fruit juice and unfrozen fruits, this technology has been used for producing packed cooked rice these days. In this way, high-pressure processed foods are becoming more and more familiar to our life in response to various needs of customers.

What benefits are provided by High Pressure?

![]()

Sterilization and Preservation Improvement

![]()

By applying high pressure instead of heat, foods can be sterilized and preserved without losing their nutritients or flavor.

Pressure Effects on Yeast (Left: Before Processing Right: After Processing at 600 MPa and 20°C for 10 min.)

(Provided by Asahi Breweries, Ltd.)

Organic Synthesis

![]()

New materials can be synthesized under high pressure, which is impossible under normal pressure. Also, specific substances can be synthesized without using catalysts. Therefore, high pressure technologies are expected to be used in the fields of fine chemicals such as medicine, pesticides, and cosmetics.

Thawing, Freezing, and Preserving in Unfrozen State

![]()

Foods can be thawed or frozen rapidly, and preserved in an unfrozen state under high pressure due to unique characteristics of water.

State of Water

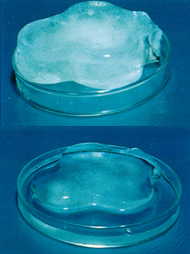

Thawing of Ice

(Top: 5°C for 3 min. Bottom: 200 MPa and 5°C for 3 min.)

Denaturation

![]()

High pressure processing can turn protein into gel, gelatinize starch and improve textures of foods.

The following figure shows the range of pressures and temperatures that are currently applied to main researches.

What are High Pressure Food Processing Technologies?

![]()

Piston Direct Pressurization Type / External Pressurization Type

![]()

Either the piston direct pressurization type or the external pressurization type is used as a pressurization method.

(A) Piston Direct Pressurization Type

The pressure medium is compressed directly by inserting a piston into the pressure vessel. This pressurization method is applied to the units with pressure higher than 500MPa.

(B) External Pressurization Type

Pressure is increased by pumping the pressure medium into the high-pressure vessel with a high pressure pump. This method is applied to the units with 500 MPa or less pressure.

Liquid Food Direct Processing System

![]()

We offer the following two types of direct processing systems for liquid foods.

(A) Free Piston Type

The pressure vessel is divided into two sections by a free piston: one filled with a liquid food, and the other filled with a pressure medium. When the pressure medium section is pressurized by the high pressure pump, the piston is pushed down to apply the pressure to the liquid food. Abrasion of packings can be significantly reduced since there is almost no pressure difference between the two sections.

(B) Flexible Wall Type

The pressure vessel is divided into two sections by a flexible wall: the inner section filled with a liquid food and the outer section filled with a pressure medium. When the pressure medium is pressurized by a high pressure pump, the flexible wall is pushed inwards to apply the pressure to the liquid food. In this case, abrasion powder is hardly mixed in the processed food because it has no sliding seal.

Continuous Processing System

![]()

High pressure processing requires continuous batch operation with multiple vessels in parallel. The figure below shows how to carry out the batch operations. In this system, three high-pressure vessels are arranged in parallel for one set of intensifier and continuously processed by staggering the processing steps of each vessel.

Energy Recovery System

![]()

A high pressure medium discharged from a pressure vessel in its decompression stage is reused for pressurizing the other pressure vessel, which leads to energy saving, reduction of the cycle time and equipment costs. This system includes production equipment combining two 130-liter pressure vessels under a pressure of 400 MPa and one set of intensifier. So, it can reduce the pressurization time in half compared with an ordinary system and requires only 4 minutes for a cycle time.

Time Comparison in High Pressure Processing

Dry Bag Processing System

![]()

The dry bag system is also effective as a highly productive method in processing packed foods. It applies pressure to packed foods placed in a pressing rubber mold by transmitting pressure through the rubber mold in the high-pressure vessel, as shown in the figure. This method is suitable for continuous processing of packed foods with its labor-saving automatic operation.

What is Hot Isostatic Pressing (HIP)?

What is Hot Isostatic Pressing (HIP)?  What is Cold Isostatic Pressing (CIP)?

What is Cold Isostatic Pressing (CIP)?  Food Technologies under High Pressuer

Food Technologies under High Pressuer

![]()