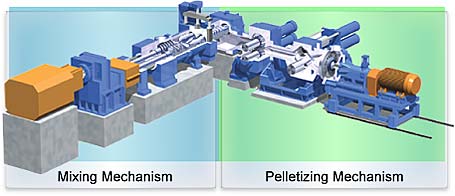

Click either mechanism above to see more details.

When compared with earlier models, the mixer power is greatly increased. This compact and high power machine is capable of coping with increased polymer capacity requirements.

The mixing rotors specifically designed by Kobe Steel provide excellent homogenization of the polymer and good dispersion of additives and pigments.

Adjustment of the gate opening and gear pump suction pressure enables mixing control over a wide operating range.

The pelletizer unit is equipped with an automatic cutting pressure mechanism, which helps to improve cutting precision and realize excellent pelletizing performance.

By isolating the mixing (LCM) and pressurizing (Gear Pump) operations it is possible for Kobe to optimize the design of each function independently to give improved mixing performance and reduced energy consumption.

Each unit is designed to realize easy start-up and minimum maintenance.

The both-ends supported rotor design means there is no wear of the rotors or the chamber due to metal-to-metal contact.

The Kobe's rich experience in designing provides the high reliability and quality of the compact gear reducer, the gear pup and the pelletizer - all of which are uniquely developed by Kobe Steel.