Home > Products > Rolling Mill・Press Machine > Foil / Sheet / Strip Mills > 1. Multi-High Mills (KT/KST Mill)

1. Multi-High Mills (KT/KST Mill)

1. Multi-High Mills (KT/KST Mill)

12-High Mill (KT Mill)

![]()

Product Summary

![]()

KT Mill (Kobe Twelve-high Mill) is a high-performance rolling mill having the respective features of our 4-high and 20-high mills, which have excellent strip flatness functions, and corresponds to the demand of improved strip flatness.

Thus, the roll arrangement of KT Mill (12-high) dominates flatness control. In addition to that, KT Mill is equipped with a wedge-type hydraulic roll-gap control system, AFC (Automatic Flatness Control System) and KOS (Kobelco Operation Support system) which are developed by Kobe Steel. These features provide optimal rolling for the application of ultra-thin stainless steel foil, Fe-Ni alloy, titanium, copper, and so on.

Typical Specifications

![]()

The following are the typical specifications. Please consult us for further information.

(unit:mm)

| Type | KT160 | KT230 | KT300 | KT350 |

|---|---|---|---|---|

| WR Diameter | 30 - 60 | 40 - 80 | 50 - 100 | 60 - 120 |

| Max. Strip width | 650 | 850 | 1,050 | 1,300 |

Structure and Illustration

![]()

The Japan Society for Technology of Plasticity

![]()

The 2010 Developed Technologies Award "Development of KT Mill for stainless steel foil"

* Publication "JOURNAL OF THE JAPAN SOCIETY FOR TECHNOLOGY OF PLASTICITY" June 2010

20-High Mill (KST Mill)

![]()

Product Summary

![]()

KST Mill (Kobe Super Twenty-high rolling mill) is a suitable rolling mill for conforming various customers' demands. It is also equipped with a wedge-type hydraulic roll-gap control system, AFC (Automatic Flatness Control System) and Kobelco Operation Support system (KOS), which are developed by Kobe Steel.

KST Mill ensures a centralized programmable control of the whole mill line as well as the most reliable automatic gauge control.

KST Mill provides the optimal rolling for the application of stainless steel, Fe-Ni alloy, titanium, copper, and so on.

Typical Specifications

![]()

The following are typical specifications. Please consult us for further information.

(unit:mm)

| TYPE | KST155 | KST220 | KST260 | KST300 |

|---|---|---|---|---|

| WR Diameter | 30 - 60 | 40 - 80 | 50 - 100 | 60 - 120 |

| Max. Strip width | 650 | 850 | 1,050 | 1,300 |

Structure and Illustration

![]()

Structure and Features of Multi-High Mills

![]()

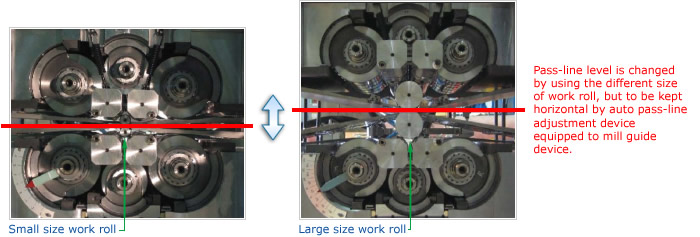

1. Use of different diameters of work rolls

![]()

Rolling mill sizes are classified into regular series by roll diameters. Work rolls of different diameters can be used.

EX):KT160 adapts work roll diameters by 30 to 60mm.

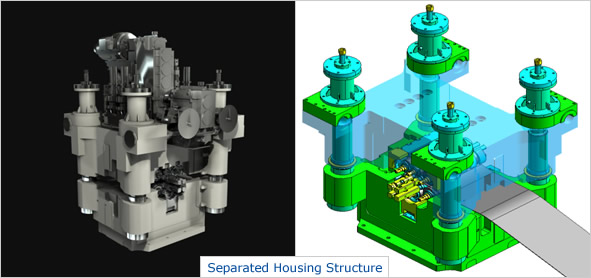

2. Separated Housing Structure

![]()

Our multi high rolling mill has unique housing structure, which is separated into upper and lower parts and connected by four columns.

As a result:

- It is easy to watch over the front and back of the strip during rolling and to feed the strip.

- The rolling load is affected by the 4 columns. With a differential sensor attached to each column, accurate rolling load detection can be carried out.

- Accurate load detection can work effectively for our own developed hydraulic Automatic Gage Control (AGC).

- Tilting-rolling by individual screw-down at the drive side and work side is possible, and is preventing strip telescoping and modifying asymmetrical flatness.

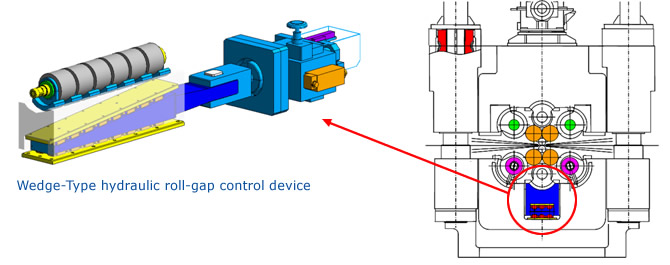

3. High gauge thickness control by Wedge-Type Hydraulic Roll-gap Control Mechanism

![]()

Roll-gap Control is performed by the hydraulic cylinder connected to a wedge built in the rear side of the back-up rolls of the lower housing. Mill housing receives rolling load directly through the wedge, so that a high-rigidity hydraulic push-up is possible. Moreover, the wedge-type hydraulic roll-gap control device achieved the world top-level high-speed control and adapts quick displacement control of strip thickness.

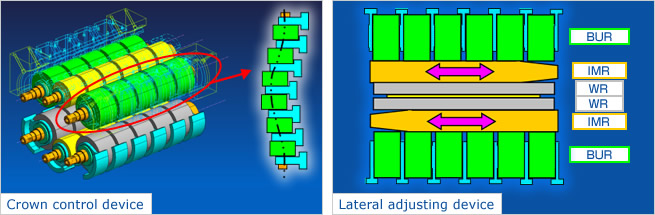

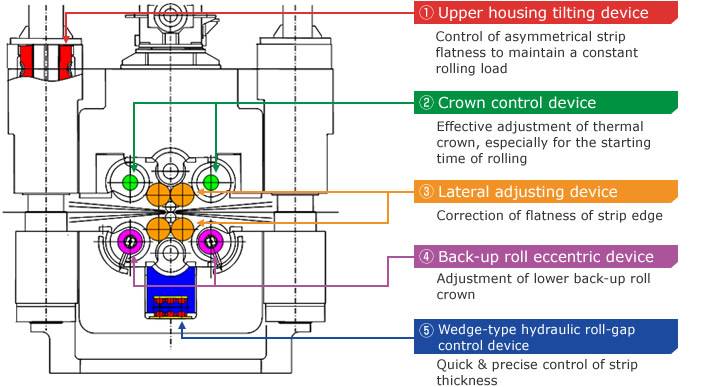

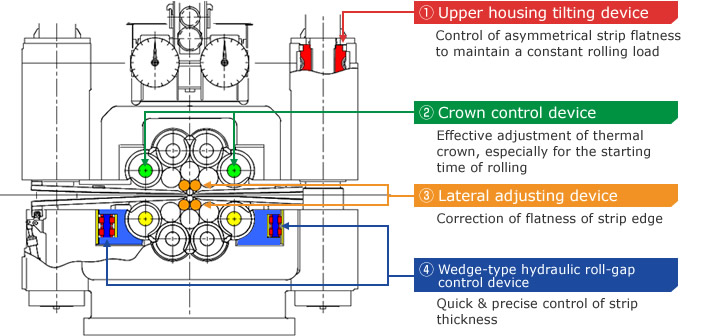

4. Uniform Product Shape with Various Flatness Control Mechanisms

![]()

Our 12- or 20-high rolling mill is equipped with such adjusting mechanisms as crown, intermediate roll lateral, and tilting-rolling for flatness control measurement. In addition, feed back control is possible with the Automatic Flatness Control System (AFC).