Home > Press Releases > 2007 > Kobe Steel forms alliance with Cleveland-Cliffs to promote ITmk3® ironmaking technology

Press Releases

The information on this Web site is presented "as is." Product availability, organization, and other content may differ from the time the information was originally posted. Changes may take place without notice.

![]()

Kobe Steel forms alliance with Cleveland-Cliffs to promote ITmk3® ironmaking technology

Kobe Steel forms alliance with Cleveland-Cliffs to promote ITmk3® ironmaking technology

June 20, 2007

The agreement, which has a 10-year term, enables the two companies to collaborate in commercializing the ITmk3 Process. Cleveland-Cliffs is granted a non-exclusive license to use the ITmk3 process and is able to freely promote ITmk3 projects mainly in the United States, Canada, Brazil and Australia. Kobe Steel will provide technical support for project promotion and development.

With the formation of the alliance, Cleveland-Cliffs and Kobe Steel also agreed to develop a commercial-scale ITmk3 plant, with an annual production capacity of 500,000 metric tons, on a joint venture basis as strategic partners at one of Cleveland-Cliffs’ United States mining properties. Cleveland-Cliffs and Kobe Steel will conduct feasibility studies and undertake the necessary environmental permitting for potential sites. The timing of this project and the site location will ultimately depend on permitting issues.

"Our alliance is aimed at expanding the use of the ITmk3 Process in major iron ore-producing countries worldwide,"said Shohei Manabe, General Manager and head of Kobe Steel's Iron Unit Division. "ITmk3 offers an attractive alternative for mineral processing. For steelmakers planning to expand capacity and mining companies seeking to broaden their product range, the ITmk3 Process holds the promise of a cost-effective method of producing high-quality iron units for steelmaking," he said.

Commenting on the new alliance, Cliffs Chairman, President and Chief Executive Officer Joseph A. Carrabba stated: "We have been very interested in this technology since successfully testing the process in a pilot plant located at our Northshore facility. The alliance with Kobe moves us closer to realizing our mutual goal of commercializing and exploiting this innovative process.

ITmk3 (pronounced "Eye-Tee Mark Three") is an innovative technology that provides a flexible and environmentally friendly process for producing iron nuggets. Consisting of 96% to 97% iron and 2.5% to 3.0% carbon, the iron nuggets are equivalent in quality to blast furnace pig iron.

About the ITmk3 Process

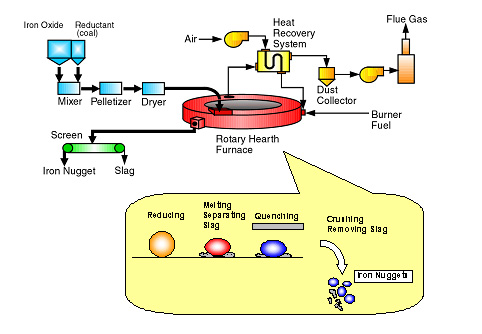

* In the ITmk3 Process, iron ore fines and pulverized coal are formed into solid "green" or raw pellets. These pellets are fed into a rotary hearth furnace and heated to 1,300-1,450 degrees C. At this temperature range, the pellets are reduced and melted, enabling the iron to cleanly separate from the slag.

* The ironmaking process takes only about 10 minutes. In comparison, blast furnace ironmaking takes 8 hours, while direct reduction can take 6 hours.

* The resulting product is iron in nugget form. The iron nuggets can then be fed to melting furnaces for refining into steel.

* Energy efficient and environmentally friendly, the ITmk3 Process emits 20% less carbon dioxide than blast furnace operations.

* Capital investment is projected at roughly half the cost of conventional ironmaking technologies. On the same scale, initial capital investment of an ITmk3 plant is estimated to be about half the initial investment cost of a blast furnace with associated facilities, including coke ovens as well as oxygen generation and supply equipment.

ITmk3 Process Flow