Home > About Us > Corporate Social Responsibility > Sustainability Report > Sustainability Report 2008 > 2. Products, Technologies and Services to Benefit the Environment

2. Products, Technologies and Services to Benefit the Environment

2. Products, Technologies and Services to Benefit the Environment

| The Kobe Steel Group has long experience in the materials field, covering iron and steel and aluminum, and the machinery and engineering field. The Group has developed production technologies, engineering technologies and know-how that are now being used in products, technologies and services to help conserve the environment. |

| Materials Field |

| The Kobe Steel Group, as a comprehensive producer of materials, uses its advanced technologies developed over many years, balanced by its comprehensive strength in manufacturing, processing and product development, to create and supply unique products for the auto industry, which include high-grade steel sheet, wire rod for valve springs and aluminum parts. In this way we contribute to lighter, safer, more environment-friendly vehicles. We also supply other products that reduce the environmental impact, such as chromate-free steel sheet and aluminum soundproofing materials. |

| Steel parts that help reduce vehicle weight |

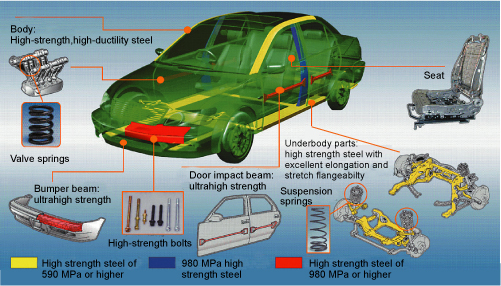

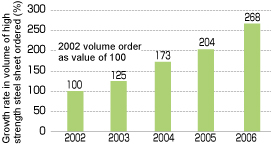

| Amid growing requirements for lighter auto parts to improve fuel economy in vehicles, Kobe Steel is leading the world in research and development of high tensile steel sheet, and has set up a system for mass production. The company also contributes to environmental conservation using its expertise in specialty steels for the commercial production of the world's highest strength steels for springs and bolts. |

Examples of steel products used in vehicle parts

| Wire rod for engine valve springs | |

| Kobe Steel has developed an ultra-high strength steel for next-generation engine valve springs, KHV12N, by furthering the technology to reduce inclusions that cause springs to fracture with increased quantities of alloy element additives such as vanadium. These springs are critical parts that control the action of the air intake and emission valves in engines and must be of high strength and high durability so as not to fracture under repeated loads of several thousand times per minute, in cars traveling distances of over 100,000 km over a 10-year period. This newly developed material has a fatigue strength 50% higher than standard steel, and valve springs can be made 50% lighter in weight. Cases have confirmed that when used in automobiles it is possible to improve fuel economy by 2%. |  Wire rod for engine valve springs |

| High strength steel sheet | |

| Our high strength steel sheet is a continuously evolving material that utilizes know-how on chemical composition acquired from our experience in specialty steels and on controlled rolling with heat treatment. With high formability developed from our own structure control technology, our high strength steel is used widely in vehicle bodies, functional components such as bumpers and door impact beams, and seat parts that require complex processing. |

|

|||||

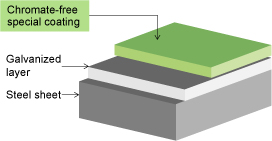

| Chromate-free steel sheet |

| In 1998, Kobe Steel was first in the steel industry to put on the market a chromate-free steel sheet, Zinkobella GX-COTE, as a substitute for chromate-coated electrogalvanized steel sheet. Since then, chromate-free products have been consistently upgraded so now all galvanized steel sheet is chromate-free. Chromate-free steel sheet products are usually surface-coated with other additives that offer the same functions of chromate coating and are equally or more resistant to corrosion, have good paintability, and are suitable for welding. They provide a high-level response to customers' requirements for a more environment-friendly material and have helped make a better working environment at steelworks. |

Chromate-free steel sheet |

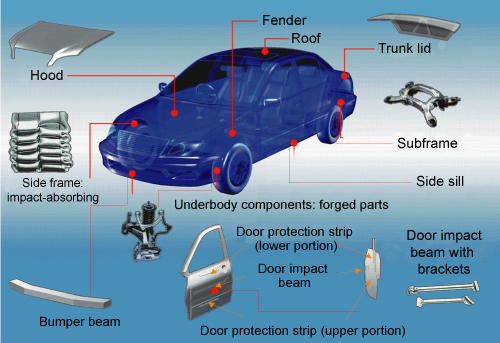

| Aluminum products that help reduce vehicle weight |

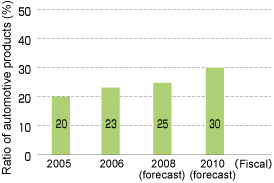

| Kobe Steel supplies aluminum products for the auto industry that include sheet for hoods and doors, extrusions for bumpers, and forgings for underbody components such as suspensions. The use of aluminum lightens vehicle weight, contributing to greater fuel efficiency. As a result of the wider use of aluminum for forged suspension parts, bumpers and panels, for which production has been increasing both in Japan and the United States, automotive products accounted for 20% of sales in the Aluminum and Copper Company in fiscal 2005, growing to 25% in fiscal 2008. The figure is expected to increase further to 30% in fiscal 2010. |

Examples of aluminum products used in automotive parts

| Ratio of automotive product sales to total sales in the Aluminum and Copper Company: Results and forecasts | |

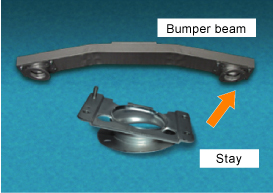

| Aluminum bumper system for vehicles | |

| Kobe Steel has developed for commercial production the world's first aluminum stays for aluminum bumper systems made by using an electromagnetic forming process. Stays are the parts that connect the bumper beam to the vehicle body, and the use of aluminum stays reduces weight by about 1.3 kg, compared with conventional steel stays. As the bumpers are located at the extreme front and rear of the vehicle, distant from the center of rotation, their light weight also reduces rotational moment, thus improving driving stability. |  Aluminum bumper system for cars |

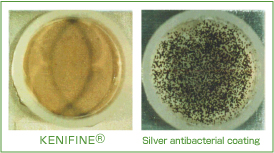

| Antibacterial coating KENIFINE® |

| Kobe Steel has developed an antibacterial coating technology called KENIFINE®. It is an electrolytic nickel-alloy plating for metal products and has excellent antibacterial and antifungal properties. It has applications in many different fields where cleanliness is critical, including medical and health services, and the food processing, electrical equipment, air purification and fishing industries. |

Test method: Black koji mold was grown on a PDA culture medium, and spores were scraped off the PD culture medium to make a culture solution. The test specimens were inoculated with the culture solution and maintained at 28 degrees C for 48 hours. |

|||||

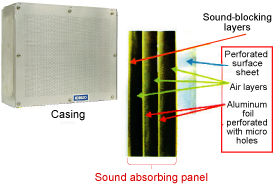

| High-Performance Aluminum Sound-Absorbing Panel |

| Kobe Steel and Shinko Kenzai, Ltd. have developed the world's first soundproof wall that uses a sound-absorbing structure made of aluminum foil perforated with micro holes. Designed for outside use, this wall uses aluminum and steel sheet to block sound as in conventional products, but to absorb sound, aluminum foil perforated with large numbers of micro holes is used instead of the usual fiber sound-absorbing material. The fine aluminum foil has holes about the same diameter as the foil thickness, and layers of foil are set adjacent to the sound-blocking sheet with layers of air in between. When used along highways or railways, around machinery or around the boundary of industrial plants, this product gives a higher soundproofing effect than conventional fiber-material, which is commonly used. Aluminum makes this an environment-friendly product that is resistant to sunlight and easy to recycle. |

Structure of aluminum sound-absorbing panel |

| Machinery and Engineering Field |

| Utilizing a wealth of experience built up in the industrial machinery field, as well as strengths in technologies and engineering and the general know-how to respond to customers' needs, the Kobe Steel Group contributes to environmental conservation by supplying compressors and construction machinery with improved energy-saving performance, and new ironmaking technologies with energy-saving potential. Furthermore, we have considerable experience in the fields of water purification, waste processing and recycling. We supply many types of environment-friendly equipment for water purification and waste treatment. |

| Kobelion standard Compressors |

| To accommodate low line pressure, Kobe Steel now supplies Kobelion standard compressors developed under the concept of 'reliability, innovation, optimal performance and environment-friendliness. These compressors achieve significant reductions in energy loss. The high rotation speed of the IPM high-speed motor increases the volume of airflow by up to 32% compared with conventional compressors. By providing users with maximum airflow at the optimal pressure, a compressor one rank lower than usual can be used, saving up to 21% of running costs. |  Kobelion Standard Compressors |

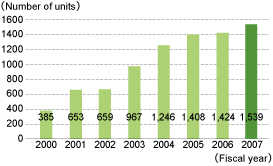

| Annual sales of Kobelion compressors | |

| Compact Screw-Type Steam Power Generator M.S.E.G. |

| As an application of the company's expertise in screw technology, Kobe Steel has jointly developed and launched the world's first high-performance screw-type compact steam generator, the M.S.E.G. (Micro Steam Energy Generator), with Group companies Shinsho Corporation and Shinko Engineering Co., Ltd., and a company specialized in steam engineering, TLV Co., Ltd. This equipment was developed in response to recent demand for energy-saving and can be effectively employed with a low volume of steam, which is the form of heat energy most widely utilized in industry. With the small flow of steam of up to 3t/hour at less than 10 atmospheres typically produced by the boilers used at manufacturing plants, waste disposal facilities and hospitals and using steam energy used when the pressure is low, up to 100 kW of power can be efficiently generated by this screw-type generator. From the positive appraisal of the M.S.E.G. for its high energy-saving performance and because it can be used for small- and medium-sized plants, it was awarded the Prime Minister's Award in the Japan Industrial Techniques Grand Prix. |

Compact screw-type steam generator M.S.E.G.  Kobe Steel Chairman Koshi Mizukoshi receiving the Prime Minister's Award in April 2008 |

| Biogas Upgrading System |

| The Biogas Upgrading System refines digester gas generated in sewage treatment to make high-quality gas of similar grade to city gas. This technology was developed by Kobelco Eco-Solutions in cooperation with Kobe City and the Public Works Research Institute, an independent organization. Digester gas (60% methane, 40% CO2) is of low grade and contains impurities, but the Biogas Upgrading System boosts the methane purity to 97% or higher and eliminates impurities. It biogas currently used to power Kobe City buses and other municipal vehicles. When biogas is used as a fuel, the CO2 emitted by engines is differentiated from that emitted after burning oil and other fossil fuels and is not counted as a greenhouse gas. It is hoped biogas can be widely utilized in the future as an efficient and environment-friendly energy source. |

Biogas Upgrading System  Biogas station |

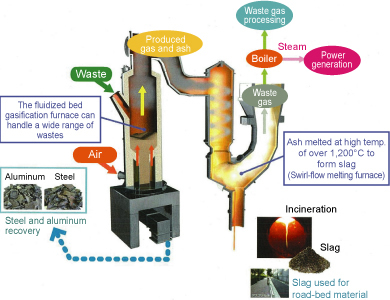

| Gasification Melting System |

| By utilizing the energy contained in wastes for combustion at higher temperatures than conventional incineration systems, the gasification melting furnace limits emissions of hazardous substances and reduces volumes by turning ash into molten slag, thereby contributing to lightening the environmental impact. Kobelco Eco-Solutions has created the world's first practical application of a fluidized bed-type gasification melting system to handle city garbage. The company is an industry leader, receiving a total of 12 orders since the plant was first launched commercially in 1999. Four of the 12 plants are still under construction. Continuous operation generally means a total of 90 to 120 days, but at the Okuetsu facility in Ono, Fukui Prefecture, a fluidized bed gasification melting furnace for refuse incineration was in continuous operation for 228 days. This is the result of efforts to redesign the refractories for longer life and improve the design technology of the melting furnace to maintain a constant temperature above 1,250 degrees C. For the local government body that commissioned the plant, the facility's stable operation has led to lower maintenance costs. |

Fluidized bed gasification melting system |

Okuetsu facility |

| Circulating fluidized bed sewage sludge incineration Plant |

| In addition to long-standing customer needs to reduce the volume of sewage sludge and render it harmless, greater attention has been focused on reducing the greenhouse gases emitted during sludge incineration. To respond to these issues, Kobelco Eco-Solutions offers a circulating fluidized bed sewage sludge incineration plant with higher efficiency and better performance compared with other types of incineration facilities. Five plants have so far been commissioned. The incineration facility is compact and requires less fuel and electricity for operation. It's emission gases are extremely clean, falling well within the regulatory standards. In the future, by improving the heat recovery, Kobelco is aiming to increase the applications of this technology and contribute further to building a recycling-based society with this low-cost, environment-friendly equipment. |  Incineration system |

| H2-PSA Process that Uses CO Selective Adsorbent |

| The reformed gas obtained from purifying natural gas contains hydrogen, carbon monoxide, carbon dioxide and methane. The removal of carbon monoxide has long posed difficulties, and the recovery rate for hydrogen has been limited to about 70%. Kobe Steel has improved the elimination of carbon monoxide and recovered 80% of hydrogen of at least 99.99% purity, by using an adsorbent with a copper compound additive that boosts absorbing capacity by seven times. This lowers the cost of hydrogen production and the equipment is more compact. It is hoped it can contribute to the wider use of fuel-cell electric vehicles as part of a future hydrogen-fuelled society. |

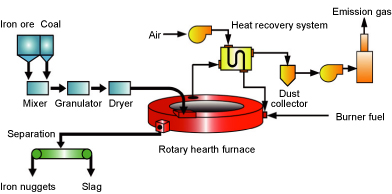

| The ITmk3® Process: Next-generation Ironmaking Technology |

| The ITmk3® Process is a groundbreaking method of creating high-grade iron nuggets in a short time. Pulverized iron ore and steam coal are mixed, granulated and pelletized. The material is then placed in a donut-shaped rotary hearth furnace and heated for about 10 minutes to undergo reduction. The slag separates, leaving iron nuggets. This next-generation ironmaking process provides a high-purity iron unit that is easy to transport. Having worked on developing new types of furnace since 1996, Kobe Steel successfully achieved continuous production at a demonstration plant in Minnesota, USA, which concluded operations in July 2004. Kobe Steel has since been working on building the first commercial-scale Itmk3® plant. In November 2007 an agreement was signed with Steel Dynamics Inc., a steel company based in Indiana, USA, to set up a joint venture to build a plant with an annual production capacity of 500,000 metric tons of iron nuggets. Located at Hoyt Lakes, Minnesota, operation is due to start in mid-2009. |

Iron nuggets from the ITmk3® Process |

| ITmk3®Process | |

| Waste Vegetation Pulverizer for Biomass Utilization |

| Shinko Engineering Co., Ltd. supplies a waste vegetation pulverizer that can turn plant waste matter into usable resources. By breaking down and swelling the biomass of woody material, the plant waste can be turned into fertilizer or feed for livestock. This equipment also has the potential for wider applications as a pre-processing technology for "green" composite material. By making effective use of biomass we are helping to create a low-carbon society. |  Shokusenki with feeder |

| Low-Noise Hydraulic Excavator |

| Kobelco Construction Machinery is marketing four models in its Acera Geospec SR series of 12-to-23 ton-class hydraulic excavators that are exceptionally quiet. Using a Kobelco-developed engine cooling system, these machines offer the ultimate in low noise-5 dB lower than Japan's Ministry of Land, Infrastructure and Transport standard of 100 dB for designation as an ultra-low noise machine. The airflow through the engine compartment follows a single contained course from intake to outlet to minimize leakage of noise. Utilized for worksites where noise must be kept low, such as urban areas or nighttime work, these machines help to minimize noise pollution in the environment. |  Acera Geospec SK225SR |