Home > About Us > Corporate Social Responsibility > Sustainability Report > Sustainability Report 2009 > Policy and Framework for Environmental Management

Policy and Framework for Environmental Management

Policy and Framework for Environmental Management

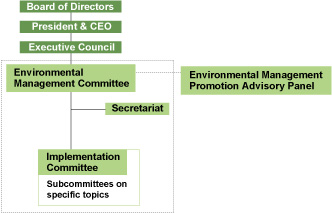

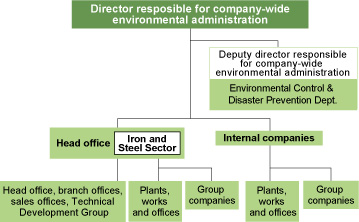

To promote Groupwide environmental management, we implement activities based on six principal initiatives. Adhering to relevant laws and regulations, Kobe Steel is rigorously pursing environment-friendly manufacturing in every aspect of its operations, including the siting and construction of its facilities, the equipment it uses, and procurement, production, distribution and product recycling. Kobe Steel provides products, technologies and services that help reduce its environmental impact with the full participation of its employees.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||