Home > About Us > Corporate Social Responsibility > Sustainability Report > Sustainability Report 2009 > Countermeasures for Air Emission Problem at Steelworks

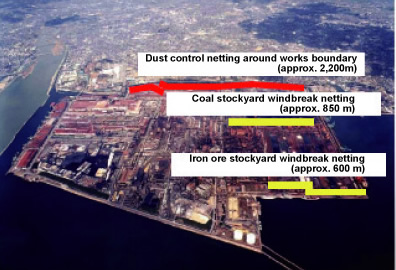

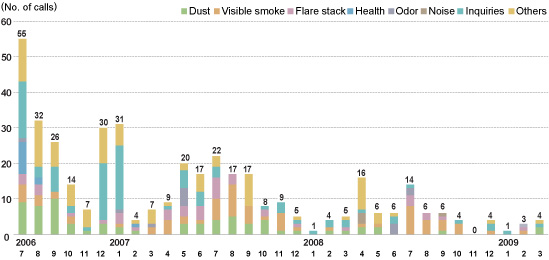

Countermeasures for Air Emission Problem at Steelworks

Countermeasures for Air Emission Problem at Steelworks

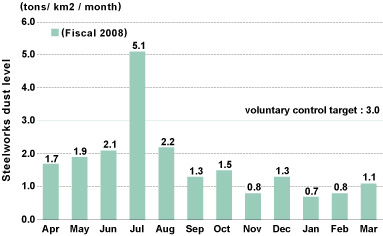

Steelworks dust level: Total quantity of insoluble dust particles recorded at set location minus the quantity of naturally-occurring insoluble dust particles (average of five recorded levels at city locations distant from steelworks)

|