Home > About Us > Corporate Social Responsibility > Sustainability Report > Sustainability Report 2009 > Material Balance

Material Balance

Material Balance

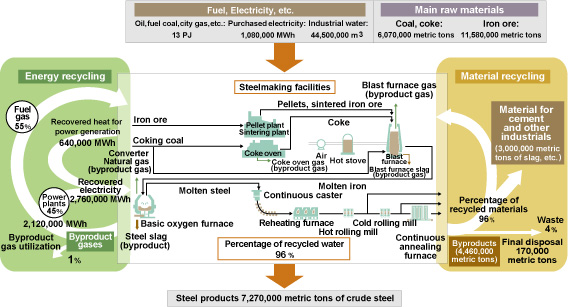

| The Kobe Steel Group is extending its environmental management to take account of the environment in all its diverse business activities. Improving energy efficiency and turning wastes into recycled resources are ongoing activities that form part of this. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||