Home > About Us > Corporate Social Responsibility > Sustainability Report > Sustainability Report 2009 > Reducing the Environmental Burden

Reducing the Environmental Burden

Reducing the Environmental Burden

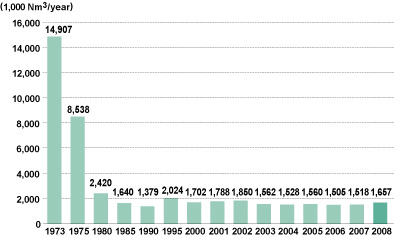

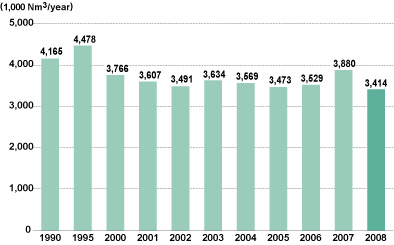

*Data for 1990, 1995, 2000 are aggregates of Kakogawa and Kobe works.

|

||||||||||||||||||||||||||||||||||||||||