Home > About Us > Sustainability Management > Sustainability Report > Sustainability Report 2010 > Policy and Framework for Environmental Management

Policy and Framework for Environmental Management

Policy and Framework for Environmental Management

Environmental Management Promotion

| Enhancing the Group's environmental capabilities through environmental management initiatives involving all employees |

|

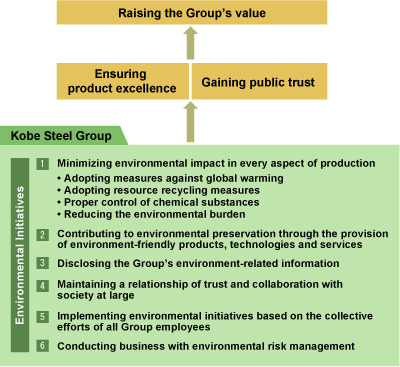

Basic Environmental Management Policy

|

| To promote Groupwide environmental management, we implement activities based on six principal initiatives. Adhering to relevant laws and regulations, the Kobe Steel Group rigorously pursues environment-friendly manufacturing in every aspect of its operations, including the siting and construction of its facilities, the equipment it uses, and procurement, production, distribution and product recycling. The Group provides products, technologies and services that help reduce its environmental impact with the full participation of its employees. |

Groupwide Environmental Management Initiatives

Group Environmental Management System

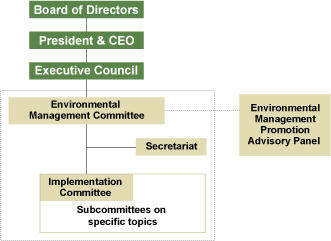

| Environmental management within the Kobe Steel Group revolves primarily around the Environmental Management Committee. In an effort to reinforce measures to tackle a range of environmental issues, the Global Environment Committee (established in 1992) was reconstituted as the Environmental Management Committee in 2002, since which time it has continued to handle environmental management on behalf of the Kobe Steel Group. Subcommittees have been set up to study specific issues such as action on global warming, and to facilitate a swift and targeted response. In fiscal 2009, an Environmental Management Promotion Advisory Panel was set up within the Environmental Management Committee to provide a framework through which to seek advice from outside experts as and when necessary. |

Environmental Management Committee, September 2009 |

Environmental Management System of the Group |

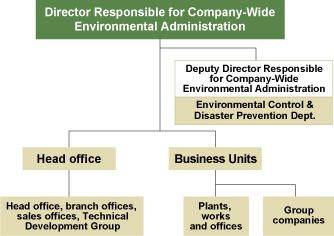

Environmental Administrative Structure of the Group |

Building an Environmental Management System

| The Kobe Steel Group is continuously and productively engaged in efforts to ensure compliance with all relevant laws and regulations and to protect the environment. To this end, we encourage obtaining certification that includes ISO14001 certification in environment management systems (EMS), the Japanese Ministry of Environment's Eco-Action 21 and the Kobe Environmental Management System (KEMS) of the Kobe Environmental Forum. In fiscal 2009, three more Group companies were certified. All 11 Kobe Steel plants have obtained environmental management system certification, and a total of 48 Group companies have also been certified. |

Topics

|

|||||||||||||||

|