Home > About Us > Sustainability Management > Sustainability Report > Sustainability Report 2010 > Reducing the Environmental Impact

Reducing the Environmental Impact

Reducing the Environmental Impact

|

|

|

Measures to Counter Atmospheric Pollution

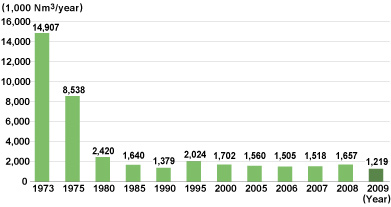

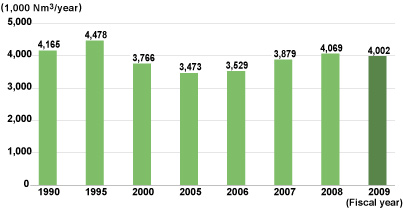

Smoke emissions

| In addition to taking steps to reduce sulfur oxide (SOx) emissions from production processes and other sources, through initiatives such as saving energy to reduce fuel consumption and using low sulfur fuels, we continue to subject emissions to desulfurization treatment and other such measures. In terms of nitric oxides (NOx), we are focusing on reducing emissions through initiatives such as installing low NOx combustion technology and energy-saving measures. |

Volume of Sulfur Oxide Emissions (Parent only)

Volume of Nitric Oxide Emissions (Parent only)

*Data for fiscal years 1990, 1995 and 2000 are aggregates of Kakogawa and Kobe works.

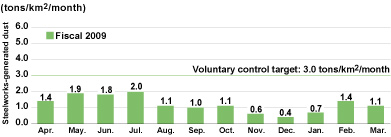

Dust control measures at the Kakogawa Works

| To reinforce dust control measures, in April 2008 we set out a voluntary control target of less than 3.0 metric tons of steelworks-generated dust per square kilometer per month in three locations in the vicinity of our steelworks that are monitored by Kakogawa City (Kakogawa Shinko Building, Befu Elementary School and Onoe Elementary School). We implemented a number of measures in fiscal 2009, including increasing the dust collection capacity of our crushing facilities, installing tire washing equipment and taking steps to control rainwater in our stockyards. As a result, we successfully cleared our steelworks-generated dust targets in all monitored locations. We will continue to step up dust control measures in the future. |

Washing tires at the Kakogawa Works |

Levels of steelworks-generated dust (Kakogawa Shinko Building)

| * | Steelworks-generated dust: The total volume of insoluble dust particles recorded at the specified monitoring location minus the volume of naturally-occurring insoluble dust particles (average from five monitored locations in other parts of the city, away from the steelworks) |

Installing volatile organic compound (VOC) removal equipment, etc.

| To reduce the volume of VOC released into the air at the Moka Plant, we have fitted a regenerative thermal oxidizer to our No.3 tension leveler. For other cleaning processes, we have switched from cleaning with organic compounds to cleaning with warm water in order to reduce the volume of organic compounds used. |

VOC removal facilities at the Moka Plant |

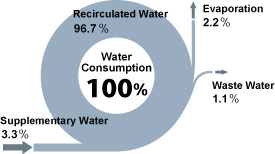

Water Pollution Prevention

| In the Kobe Steel Group, the water consumption rate is being reduced by improving production processes and using recycled water. Wastewater from production processes is purified via treatment systems best suited to the properties of the relevant water so as to reduce the impact of water-polluting substances on public water supplies. Once wastewater from individual production processes at our steelworks has been purified, it is then reused onsite via our water recycling system. We have achieved a water recycling rate of approximately 97% at the Kakogawa Works and the Kobe Works. |

Water recycling |

Noise Reduction

| We implement various measures to minimize the impact that noise from our plants has on the local area, including only using noise-producing equipment inside buildings and installing soundproof walls and vibration-proof pads to block or absorb noise. We also make every effort to maintain and operate all machinery in good working order so as to prevent abnormal noise levels. |

Odor Reduction

| Measures are taken to control odors generated at works and plants based on periodic monitoring and information obtained from local residents. |

Preventing Ground Contamination

| In addition to complying with the Water Pollution Control Law and other applicable legislation and preventing contaminated water from seeping into groundwater, we make every effort to prevent soil contamination through initiatives such as effectively controlling hazardous substances at all of our premises. |