Home > About Us > Sustainability Management > Sustainability Report > Sustainability Report 2010 > Relations with Customers and Business Partners

Relations with Customers and Business Partners

Relations with Customers and Business Partners

| Earning trust and ensuring satisfaction through rigorous quality control based on ISO 9000 series certification |

|

Iron & Steel Sector

Quality Assurance

|

Establishing a new quality assurance system

| At Kobe Steel's Kakogawa Works, we are looking at the nuclear power and energy sectors, in which demand is expected to increase, and have established a quality assurance system that is compliant with ASME Section III (US nuclear power regulations). In line with ISO/TS16949 quality assurance certification for the automotive industry, which is already in place, and quality assurance system certification in accordance with the Pressure Equipment Directive and other legislation, we are in the process of establishing a framework that is capable of meeting requirements across a wide range of sectors and regions. |

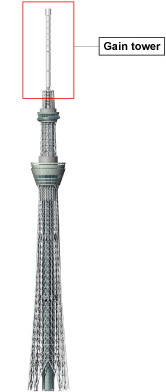

Circular steel pipe used for top part of Tokyo Sky Tree®

| The strongest circular steel pipe currently available in the domestic market was developed in conjunction between Kobe Steel and Sasaki Pipe & Tube Co. Ltd. and is being used in the gain tower on top of Tokyo Sky TreeR, to which broadcast antennas will be attached. The circular steel pipe iis noted for its low yield ratio, weld crack prevention, and has high toughness in the weld heat zone, making it highly earthquake-resistant. Unique to Kobe Steel, the low carbon fine bainite technology used in the steel tube won the Japan Welding Engineering Society's 2009 Technology Prize for its outstanding contribution in terms of increasing the toughness in the weld heat zone. |

The gain tower on Tokyo Sky Tree® made from circular steel pipe |

Working to Enhance Customer Satisfaction

Operating a System that Responds Quickly to Customer Requests

| The Iron and Steel Sector operates a Japanese website through which we provide quick answers to requests and inquiries received from customers about our many iron and steel products. The website has proven very effective in our efforts to provide explanations on new products and technologies. To enhance customer service still further, we provide technical services that provide timely responses to customer inquiries. This function has four operating centers in Japan and five abroad (in North America, China and Southeast Asia), enabling us to respond quickly on a global basis. |

Technical Exchange Meetings in the Shipbuilding and Construction Fields

| Kobe Steel sponsors regular meetings with shipbuilders, construction companies, design companies and manufacturers to provide a forum for the introduction of new products and technologies. Through these exchanges of technical information, we can pursue technologies that match customer needs and engage in joint research focused on such areas as new product development and proposals for more rational solutions for building steel structures. In fiscal 2009, we held more than 20 meetings. To encourage customers to use our products, we also provide customers with suggestions about such things as how they can improve their processing methods and equipment for greater efficiency and safety. In fiscal 2009, we started to work with the Welding Company so as to incorporate related welding technologies and provide integrated solutions. |

Welding Company

Assuring Quality and Product Safety

|

Customer Support Centers Create Kobelco Fans

| The Welding Company operates customer support centers that provide our customers and business partners with technical support. We also provide on-the-job training for all members of our nationwide sales network, comprised of companies belonging to the Shinyokai, Kobe Steel's welding association, and hold welding contests, technical tutorials for certification tests, and study groups aimed at strengthening our technical and sales capabilities. The ultimate goal of this technical support is to nurture trust and reassurance among our customers and business partners. To this end we also hold technical exchange meetings to introduce new products and processes to customers. This support, tailored closely to customer needs, is how we build a base of "Kobelco fans." |

Welding Demonstrations

| We operate two vans, one in western Japan and one in eastern Japan, equipped with everything needed to conduct welding demonstrations. The demonstrations have proven very popular among customers who find it easy to understand the welding process when it's performed right before their eyes. |

Shinyokai Supporter Certification System

| The Welding Company set up the Shinyokai Supporter Certification System in 2004. Although activities were slated to end in 2008, we extended the scheme by a further three years in response to strong demand from Shinyokai members and are continuing to work on improving technical standards. As a result of our activities, approximately 1,600 welders throughout Japan have passed practical and written welding tests and been certified as Shinyokai Supporters (as of the middle of 2009). The number of Expert Supporters with a higher level of expertise meanwhile currently stands at 65. |

Holding regular international quality control meetings

| In October 2009, the 13th international quality control (QC) group meeting took place at Fujisawa Industrial Operations. Approximately 200 employees from six domestic sites and five countries outside Japan took part in the meeting, which outlined a total of 11 domestic and overseas case studies. The Welding Company is committed to improving quality standards on a global basis through activities such as these. |

Aluminum and Copper Company

Quality Management System (QMS) Operates in Business Units

|

Certified by Global Quality Systems in Numerous Fields

| The Aluminum and Copper Company is active in the automotive, aerospace and shipbuilding fields, and has received global certification in all of them, including ISO/TS 16949, ISO 9001, JIS Q 9100, NADCAP, Boeing, GE and ship registry companies. We continue our commitment to product quality control that is internationally recognized in a wide range of industries. * NADCAP (National Aerospace and Defense Contractors Accreditation Program) is a certification program developed by the Performance Review Institute of the United States. It is the only fully integrated certification program in the world and has become the global standard for certifying the specialized processes used in aerospace industries. |

Technical Exchange in Thailand and Malaysia to Achieve Same Global Quality Standard

| Kobelco & Materials Copper Tube, Ltd. is actively engaged in technical exchange and support provided by its main production facility, the Hatano Plant in Japan, directed toward its plants operating in Thailand and Malaysia. In fiscal 2009, we organized a three-way meeting and stepped up efforts for personnel exchanges and to share quality information via the intranet, harnessing the group's combined capabilities to achieve the same global quality standard. |

Received the "Outstanding Partner Award" from Mitsubishi Heavy Industries' Nagoya Guidance & Propulsion Systems Works

| Having worked on quality improvement activities in conjunction with Mitsubishi Heavy Industries' Nagoya Guidance & Propulsion Systems Works, the Aluminum and Copper Company has been commended as an outstanding partner, in recognition of the fact that its magnesium cast and forged products, used in helicopters and other aircraft, have helped to significantly reduce internal defects. |

Machinery & Engineering Company

Promoting Early-Stage Product Quality Monitoring Activities

|

Kobelion® SD wins Japan Industrial Technology Grand Prix Special Jury Prize

| Developed in conjunction with leading compact through-flow boiler manufacturer Miura Co. Ltd., the Kobelion® SD DS1310-HR compression heat recovery stream-driven air compressor won the Special Jury Prize at the 39th Japan Industrial Technology Grand Prix sponsored by Nikkan Kogyo Shimbun, in recognition of its unrivalled energy saving capabilities and environmental performance. Kobelion® SD is a groundbreaking product that reduces running costs by around 85% and cuts CO2 emissions by approximately 90% by using a steam motor as its power source and recovering compression heat so that the heat can be used to preheat boiling water instead of being emitted into the atmosphere, as was the case previously. The compressor is expected to make a significant contribution in terms of cutting industrial overheads and reducing environmental impact. |

The award ceremony |

Global quality improvement initiatives

| The Standard Compressor Plant (Harima/Takasago) hosts monthly Plant Quality Meetings with Kobelco Compressor Manufacturing (Shanghai), our standard compressor manufacturing subsidiary in China, and makes every effort to improve global quality standards in its capacity as our main air compressor plant. |

Kobelion® SD and SteamStar® honored at award ceremony for successful energy conservation

| The Energy Conservation Center, Japan (ECCJ), an organization under the jurisdiction of the Ministry of Economy, Trade and Industry's Agency for Natural Resources and Energy, picks out successful examples of energy conservation in each region and organizes awards in recognition of the relevant achievements and as a means of sharing technology. At the fiscal 2009 award ceremony for the Kanto region, the Energy Conservation Center Award went to Dia Chemical Co. Ltd., which uses Kobe Steel's KobelionR SD compression heat recovery stream-driven air compressors. An award for excellence was also given to Sanko Co. Ltd., which uses Kobe Steel's SteamStarR screw-type compact steam generators. We will continue to develop products that our customers can put to effective use in the future. |

Group Companies

Kobelco Eco-Solutions Co., Ltd.

Maintenance Seminars for Process Equipment

| The Customer Service Department at Kobelco Eco-Solutions invites customers' maintenance personnel to the Harima Plant to take part in maintenance seminars in an effort to improve after-sales services. It also strives to improve customer satisfaction through initiatives such as organizing offsite seminars at the request of the customer. In fiscal 2009, Kobe Eco-Solutions established a record management system and provided services such as tailored routine visits and improvement proposals. |

Bio Natural Gas Generator wins Minister of Economy, Trade and Industry Award

| Developed as part of a three-way project between the City of Kobe, the Public Works Research Institute and Kobelco Eco-Solutions, the Bio Natural Gas Generator, a system designed to refine sewage sludge digestion gas (by refining gas produced by sewage sludge into highly concentrated methane gas), won the Minister of Economy, Trade and Industry Award at the 35th Excellent Environmental Equipment Awards, organized by the Japan Society of Industrial Machinery Manufacturers. |  The award ceremony |

Kobelco Construction Machinery Co., Ltd.

Promoting high quality standardization based on the slogan "Made by Kobelco"

| Kobelco Construction Machinery holds joint quality meetings with each of its domestic and overseas plants (Hiroshima, Ogaki, two in China, and one in Thailand) and overseas subsidiaries (Singapore, India, etc.) once a year and is committed to improving quality levels on a global scale based on the slogan "Made by Kobelco," meaning that all products are of the same high quality no matter where they are made or sold. |

Kobelco Research Institute, Inc.

Using Customer Satisfaction Surveys Throughout the Company

| As part of its quality management activities based on ISO9001, the Sales Division of Kobelo Research Institute, Inc. conducts customer satisfaction surveys. Twice a year, the results are processed statistically, subjected to trend management, and reported to a company-wide management review, where they are used to help determine future policies and company directions. The survey results are also studied by each department at monthly quality meetings. In addition to the activities of the Sales Division, other divisions and operating locations pursue their own quality management activities, the results of which are also discussed at the quality meetings. |

Kobelco Cranes Co., Ltd.

Using the Internet to Better Gauge Customer Opinion

| To better reflect customer input, the Customer Support Dept. of Kobelco Cranes Co., Ltd. uses the Internet in addition to visiting customers. Its website features different access points for different categories of inquiries, including questions about new machines, used machines, parts, and technical information. In this way we collect detailed information on what customers really think. In Japan, the company offers IT controllers as standard equipment and studies how customers actually use the cranes, enabling a quantified grasp of such parameters as load and utilization rates. This information is then used in the design of next-generation products. |

Other Activities

Procurement Regulations

| Kobe Steel has established basic procedures as part of its procurement regulations that govern such aspects as the proposal and implementation of purchasing plans and the signing of contracts. The regulations stipulate that "when engaging in procurement, full consideration must be given to social conditions and demands, environmental protection, resource conservation and other concerns." Every effort is made to deal honestly and fairly with business partners and to support and nurture a relationship of trust, while strictly adhering to all laws, regulations, and social norms. In this way, procurement activities are pursued as correctly and effectively as possible. |

Responsible Exporting

| Kobe Steel is committed to appropriate and responsible exporting and has developed company guidelines governing the management of secure trade. In accordance with these guidelines, we enforce strict internal controls so as to ensure compliance with all regulations applicable to products and technologies that could be used as weapons or for other military purposes (list regulations) and regulations relating to our customers' intended purposes (catch-all regulations*). This proactive stance on security is spreading from Kobe Steel itself to all members of the Kobe Steel Group, so that each company can implement appropriate export policies as part of a comprehensive trade security system. Similarly, we are educating Group members on the RoHS (Restriction of Hazardous Substances) Directive adopted by the European Union in July 2006 and taking steps to ensure conformity. While providing our employees with e-learning and other educational opportunities to increase their knowledge level, we continue our efforts to nurture an ongoing sensitivity to changes in international conditions. *Catch-all regulations: Legislation applicable to the export of all products and technologies that could potentially be used in the development and production of nuclear weapons or in the development and production of regular weapons. |