Home > About Us > Sustainability Management > Sustainability Report > Sustainability Report 2010

Reducing environmental impact through continually evolving materials

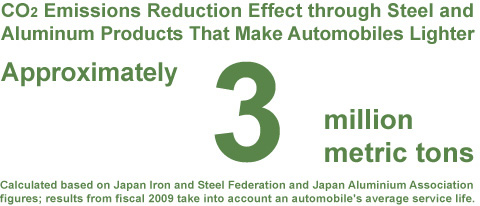

In order to reduce CO2 emissions and stop them contributing to global warming, developing lightweight cars is a top priority so as to improve fuel efficiency.

We do our bit to reduce CO2 emissions at Kobe Steel through our high-strength steel products and aluminum products designed with automotive lightweighting.

Automobile weight reduction with iron and steel products

With steel wire rod and bar, Kobe Steel develops and mass produces the world's strongest spring steel and bolt steel, contributing to lighter automobiles and higher performance engines. Kobe Steel spring steel for automotive suspension systems and engine intake valve springs enable weight reductions of 20% and 50%, respectively, compared with conventional products.

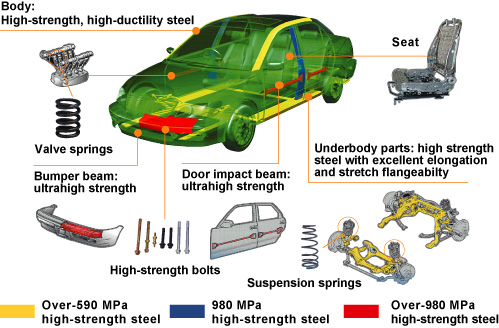

Kobe Steel is also developing and implementing a production and supply structure for high-strength steel sheet, utilizing the chemical composition expertise gained from specialty steels for wire rod and bar and the microstructure control from heating and cooling processes. Realizing high tensile strength and exceptional formability, high-strength steel sheet is an ideal material for reducing the weight of the structural components that make up the vehicle body, seat, bumper and door impact beams as well as other parts.

In addition to developing even stronger products at Kobe Steel in the future, we will continue to create products that cater to new demand for items such as motor materials for hybrid, electric and other next generation vehicles. We also intend to continue developing next generation high strength steel sheet, so as to make it more workable but just as strong, and working on the application of high strength steel sheet on more complex parts in order to contribute to lightweight vehicle development.

Examples of steel products used in vehicle parts

Remarks from the Key Technologist

Adopting a diverse approach to reducing CO2 emissions in the automotive sector

Masato Kaiso, General Manager

Wire Rod & Bar Products Development Department, Technical Development Center, Iron & Steel Business

In the wire rod and steel bar sector, we have continued to develop new products that are designed to be the world's strongest. Now that our new products are being used by our customers, we are contributing to the development of lightweight vehicles and helping to improve fuel efficiency and reduce CO2 emissions by minimizing energy loss from various sources whilst driving. In addition to improving fuel efficiency through increased strength, we are also committed to developing new products and technologies capable of reducing CO2 emissions at the component manufacturing stage in the future so as to provide the market with environmentally friendly wire rod and steel bar.

Aluminum products that reduce vehicle weight

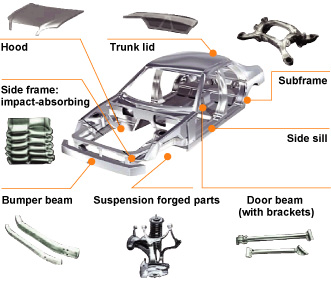

Kobe Steel was an early adopter of aluminum materials to reduce vehicle weight. Aluminum is particularly effective as panel sheet used for hoods and doors, for such extruded parts as bumpers, and for such forged underbody components as suspensions, which contribute to making vehicles more fuel efficient.

In the future, we intend to develop forming technology to enable us to expand the range of applicable parts and work on developing battery components such as casings and electrode foils for hybrid, electric and other next generation vehicles. We are also planning to establish production systems in areas such as China, which is experiencing a major surge in vehicle production, and Europe, which is introducing new fuel efficiency regulations, in order to make an even greater contribution to lightweight vehicle development and reduced CO2 emissions.

Remarks from the Key Technologist

Promoting aluminum alloy-based lightweight vehicle development on a global scale

Tadashi Aiura, Manager

Automotive Materials Planning Section, Technology Control Department, Aluminum & Copper Business

We continue to develop material, design, analysis and assembly technologies, so that we can offer our customers the best possible solutions in line with their lightweighting needs. We intend to keep on increasing product supply as part of our lightweighting solutions for auto manufacturers, in Europe and the US as well as in Japan, and helping to reduce CO2 emissions on a worldwide scale via our global aluminum alloy-based lightweight vehicle solutions.

Examples of aluminum products used in vehicle parts

Making a contribution at home and in the office through outstanding thermal conductivity

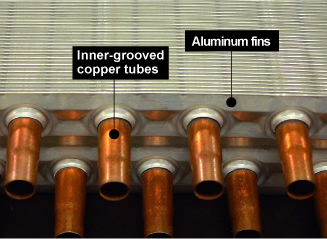

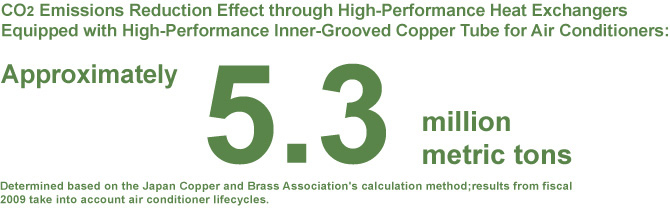

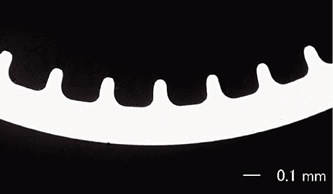

Given their high heat transfer performance and conductivity, copper products are playing a major role in improving energy savings for air conditioners, control equipment and other products. Particularly in the case of air conditioners, the development of high-performance grooved copper tubes has further raised the ability to transfer heat. This is possible by processing grooves into the interior surface of the copper tubes used in heat exchangers. Compared with 1990, there has been a two-fold improvement in air conditioner coefficient of performance (COP*); approximately one-third of this is thought to be the result of the higher performance of heat exchangers equipped with inner-grooved copper tubes.

Kobe Steel provides about 30% of the copper tubes used in air conditioners, contributing to the reduction of CO2 emissions.

* The COP index is used to state air conditioner performance, comparing the ability to heat and cool against electric power consumed.