Home > About Us > Sustainability Management > Sustainability Report > Sustainability Report 2010

New-generation ironmaking process speeds up low-carbon industrial and social development

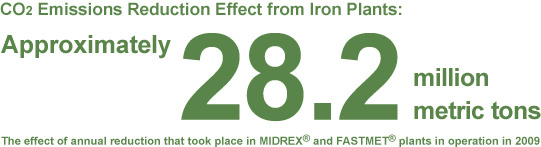

The MIDREX® Process: A way to slash CO2 emissions by using natural gas to convert iron ore into direct reduced iron

Iron ore has conventionally been reduced using lump ore or coking coal. With the MIDREX® Process, however, natural gas is used as a reducing agent, enabling substantial reductions to CO2 emissions.

Blast furnaces reduced iron ore using coke and coal. However, the MIDREX® Direct Reduction Process uses natural gas as the reductant, resulting in a considerable reduction in CO2 emissions. We have constructed MIDREX® direct reduction plants mainly The MIDREX Process provides a source of clean iron units, which is essential to the production of high-grade steel using electric furnaces. As such, demand is on the increase.

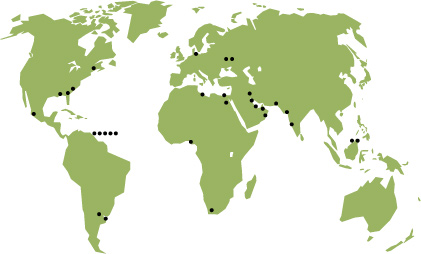

The MIDREX® Process, the license of which is held by Kobe Steel, is used in approximately 60% of direct reduced iron production worldwide. There are presently about 60 direct reduction plants around the world that use the MIDREX® Process.

MIDREX® reduction plants around the world

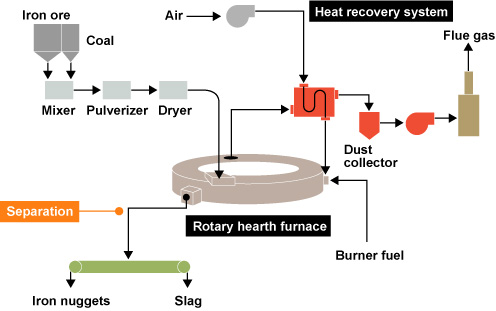

The ITmk3® Process: Tapping underutilized resources with third-generation ironmaking to open up a low-carbon future

Originally there was the blast furnace process, then the Kobe Steel Group developed the MIDREX® Process, and now there is a third generation of ironmaking, the proprietary ITmk3® Process. Taking advantage of low-grade iron ore and steaming coal that are difficult to use in conventional blast furnaces, the ITmk3® Process uses a rotary hearth furnace to produce high-purity iron nuggets. There is no need for sintering equipment for the lump ore and coke ovens for the coking coal required by blast furnaces. In addition to being able to reduce the environmental impact of NOX and SOX, there is the potential to reduce CO2 emissions by approximately 20% compared with ironmaking using blast furnaces in emerging markets or at mine sites.

In January 2010, we launched the world's first commercial ITmk3® plant in Minnesota, USA. The plant supplies iron nuggets for the production of high-grade steel using electric furnaces. We are marketing this new technology in other parts of the world, including India, Vietnam and the Ukraine.

In addition to reducing facility costs and utilizing untapped resources, ITmk3® also reduces the environmental impact and enables the production of high quality iron units. It is a truly innovativeprocess that is set to pave the way for the future.

The ITmk3® Process

Remarks from the Key Technologist

Bringing about a paradigm shift in ironmaking through ITmk3®

Hidetoshi Tanaka, General Manager,

Research & Development Department,

Iron Unit Division,

Natural Resources & Engineering Business

If you mention iron, most people tend to picture massive blast furnaces, which produce large quantities of CO2 and require high-grade raw materials. In contrast to that image, we have developed a brand new ironmaking process called ITmk3R, following in the footsteps of MIDREXR, which uses natural gas, and FASTMETR, which uses ordinary coal. After working on development for over a decade, we have finally launched the first commercial plant in the United States. We hope that this will sparka 21st century paradigm shift, moving away from existing large-scale ironmaking plants on the waterfront and toward dispersed ironmaking at raw material locations.

| Products and technologies | Description of product / technology and capabilities |

|||

| Iron & Steel |

|

Lightens vehicles for improved fuel efficiency | ||

| Automotive high-strength valve spring steel | Lightweight, compact valve springs improve engine and fuel efficiency | |||

| High-strength steel plate for ships | Lightweight steel plate improves fuel efficiency of ships | |||

| Titanium materials for aircraft | Enables lightweight aircraft development for improved fuel efficiency | |||

| Blast furnace cement | Can be used as an alternative raw material to reduce energy consumption when manufacturing cement | |||

| Aluminum & Copper |

|

Enables lightweight vehicle development for improved fuel efficiency | ||

| Aluminum extrusion components for railcars | Enables development of lightweight railcars for reduced power consumption | |||

| Aluminum and magnesium components for aircraft | Enables lightweight aircraft development for improved fuel efficiency | |||

| High-performance inner-grooved copper tube for air conditioners | Improves heat exchange performance, enabling a 100% increase in air conditioning efficiency compared to 1990 levels (30% of which is due to innergrooved copper tube) | |||

| Machinery | Ordinary compressors | Can be operated on demand, using inverter controls, in order to save energy | ||

| Screw compressors | High-efficiency screw compressors for high-pressure gas turbine fuel compressors | |||

| High-efficiency heat pumps | Uses high-performance compressors and heat exchangers to improve performance by 50% and the partial load by four times compared to existing pumps | |||

| SteamStar® | Recovers unused energy from low-pressure steam and uses it to generate electricity | |||

| Binary generation units | Uses exhaust heat to heat and evaporate liquids with low boiling points and uses the resulting steam to generate electricity Enables industrial exhaust heat and other low-temperature exhaust heats to be reused |

|||

| Air separation systems | Increases separation efficiency, reduces pressure loss and improves compressor performance, increasing efficiency by approximately 10% | |||

| Natural Resources & Engineering | MIDREX® | Uses natural gas to reduce iron ore, significantly reducing CO2 emissions compared to ironmaking in blast furnaces | ||

| FASTMET® FASTMELT® |

Produces direct reduced iron from low-grade ore and steel dust Effectively harnesses carbon contained in dust and exhaust heat to reduce CO2 emissions |

|||

| ITmk3® | Uses low-grade iron ore and ordinary coal, rendering coke processing and sintering unnecessary Reduces processing time and effectively harnesses exhaust heat, enabling reduced CO2 emissions |

|||

| Kobelco Construction Machinery Co., Ltd. | ACERA GEOSPEC | Significantly improves operational efficiency and uses fuel efficient engines to achieve a 15-20% improvement in fuel efficiency | ||

| Hybrid hydraulic excavators | Enables battery storage of surplus engine power when operating with no load or with a partial load and energy from braking when rotating in order to provide power assistance when operating with heavy loads, improving fuel efficiency by approximately 40% | |||

| Kobelco Eco-Solutions Co., Ltd. | Natural biogas | Refines gas produced during sewage treatment and reuses it as fuel | ||

| Energy-saving sewage and wastewater treatment facilities | Increases efficiency of auxiliary machinery in order to save energy and reduce volume of chemicals used |