Home > About Us > Sustainability Management > Sustainability Report > Sustainability Report 2011 > Contributing to Environmental Conservation through R&D

Contributing to Environmental Conservation through R&D

Contributing to Environmental Conservation through R&D

| Research and development speeds up commercialization of environmentally friendly "Only One" materials and machinery |

We actively promote the commercialization of environmentally friendly materials and machinery, in an effort to create and increase sales of the Kobe Steel Group's original "Only One" products. Corporate R&D provides support to our businesses in materials, machinery, natural resources and engineering. The following section outlines some of the research and development activities that underpin our efforts to commercialize environmentally friendly materials and machinery.

We make the most of the gas-handling technologies that we have developed through Kobe Steel's machinery and plant operations and the byproduct gas purification technologies used at our steelworks, to conduct research and development aimed at creating a hydrogen society, in the hope of significantly reducing CO2 emissions.

Powered by electrochemical reactions, pure hydrogen fuel cells maintain efficiency levels even at low loads, making them ideal for distributed generation. Whereas hydrogen is used on a continual, stable basis for industrial purposes, facilities need to be flexible when using hydrogen to generate and supply energy, in terms of dealing with load variations and enabling easy start-up and shut-down in the morning and at night.

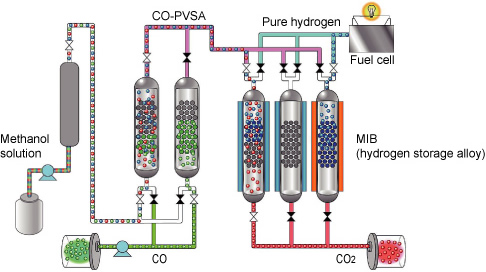

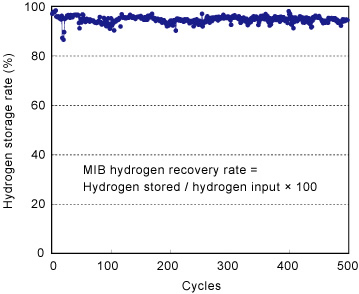

In partnership with Tsukuba University, our Technical Development Group has developed a new hydrogen purification and storage process (COA-MIB Process, Figure 1) that is compact, easy to start up and shut down on a daily basis, and highly responsive to load variations. We have already operated a 100NL/h compact system on a trial basis for over 750 hours without deterioration. Results indicate that it would be possible to supply pure hydrogen at a high recovery rate of at least 88% on a DSS (daily start and stop) basis (Figure 2).

We have also achieved an 85% hydrogen recovery rate using 3Nm3/h bench scale equipment and are currently conducting experimental research with an eye to achieving commercialization.

As this process would make it possible to flexibly manufacture and store hydrogen, so that it could be supplied to fuel cells without requiring a large-scale hydrogen network, there are high hopes that it could contribute to the creation of a hydrogen society.

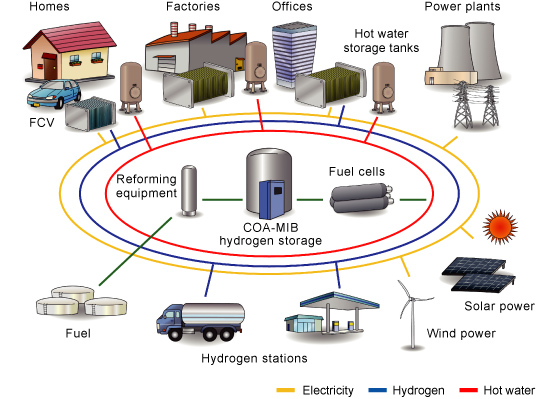

Using pure hydrogen fuel cells as batteries would resolve the issue of instability throughout the power system, which could otherwise result from an influx of natural energy from unstable sources such as solar cells and wind power. We will continue to work towards commercialization and explore the possibilities of creating a new energy network (Figure 3).

| * | The above research and development is being carried out as part of a global warming technical development project commissioned by the Ministry of the Environment. |

3Nm3/h bench-scale equipment

Figure 1. Outline of the COA-MIB Process

Figure 2. Hydrogen recovery rates achieved by a compact system operating on a

Figure 2. Hydrogen recovery rates achieved by a compact system operating on a DSS (daily start and stop) basis (1 cycle = 1.5 hours)

Figure 3. Positioning of a COA-MIB system in an energy network

Figure 3. Positioning of a COA-MIB system in an energy network