Home > About Us > Sustainability Management > Sustainability Report > Sustainability Report 2012 > Feature: Contributing to Society Through Monozukuri

Feature: Contributing to Society Through Monozukuri

Feature: Contributing to Society Through Monozukuri

Supporting society through monozukuri

The Kobe Steel Group's DNA, passed down for over a century, continues to create products and technologies in line with modern-day needs.

For over a century since the Kobe Steel Group was founded, we consider it our mission to support society through monozukuri, or manufacturing. That philosophy runs through our corporate DNA, which has enabled us to manufacture products in line with modern-day needs throughout our history.

This special feature looks at some of the cutting-edge achievements made possible by our original technologies, as we continue to contribute to society through monozukuri.

Protecting People Through Monozukuri

![]()

We want to make products that protect people's lives and their livelihoods from natural disasters.

Our engineers' hard work is now starting to bear fruit in disaster prevention and recovery support technologies.

Japan is at constant threat from nature—from earthquakes to typhoons and landslides. Here at the Kobe Steel Group, we have continued to develop unique technologies in various fields to protect people from natural disasters. This commitment to "protecting people through monozukuri" is now starting to bear fruit, in the form of disaster prevention and recovery support technologies, providing members of the public with the safety and peace of mind they need.

Coastal engineering for disaster prevention:

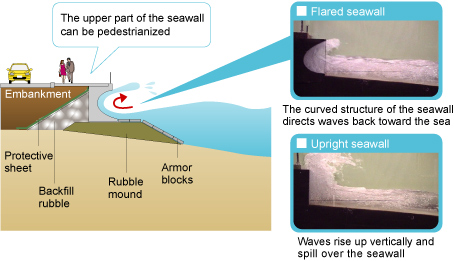

Flared seawalls deflect high tides and high waves

![]()

When waves crash into shore, they can be deflected using seawalls with a smooth curve. Developed by our Technical Development Group in conjunction with our Natural Resources & Engineering Business, our flared seawalls are attracting a lot of attention as a new form of disaster prevention infrastructure. The term "flared" is used in shipbuilding to describe the curvature of a ship's leading edge, which prevents waves from splashing. At Kobe Steel, we have put this principle into practice in coastal engineering.

When waves come up against conventional upright seawalls, the water is pushed up vertically, making overtopping waves, or waves that go over the top of the wall. If the seawall is flared on the other hand, the curved shape redirects the waves back toward the sea. Using a hybrid technology that combines steel and concrete, we have managed to develop a seawall structure that combines quality with long-term durability against waves. Flared seawalls keep high tides, caused by low pressure or typhoons for instance, at bay and can even weaken the momentum of a tsunami to some extent.

Structure of flared seawall and hydraulic testing

Protecting livelihoods as well as the environment:

More coastal areas around Japan have flared seawalls

![]()

Flared seawalls offer considerable benefits from an environmental standpoint, too. Conventional seawalls are often combined with wave-absorbing blocks, which reduce the power of the waves but can also affect the appearance of the coastline. As flared seawalls eliminate the need for wave-absorbing blocks, the upper part of the seawall can be pedestrianized, creating a pleasant waterfront space ideal for attracting tourists to the coast.

In recognition of these benefits, flared seawalls have already been constructed in eight locations in western Japan. One such location is the Betsudai National Highway in Oita Prefecture, where high-tide traffic restrictions have now been lifted as a result. In Okinawa meanwhile, flared seawalls are proving highly effective for both people and the ecosystem, providing protection for sea turtle spawning grounds and safeguarding against damage from high tides during typhoon season.

Flared seawall in Kunigami, Okinawa

Preventing landslides, preserving biodiversity with sabo dams

![]()

landslides and driftwood

Kobe Steel also supplies steel grid-type dams designed to stop major landslides (known as "mountain tsunami" in Japanese). Such dams are positioned along rivers running through mountain valleys all over Japan. Traditionally, "sabo" (erosion control) dams always used to be made from concrete. Our steel grid-type dams however are made from an arrangement of steel pipes. As water can still flow between the pipes, dams allow fish and other aquatic creatures to pass through. This groundbreaking technology therefore protects the natural ecosystem as well as prevents landslides.

We have also developed a steel sabo structure called "Bull Metal," which is small enough to be transported by helicopter. In January 2011, structures were relocated from Fugendake on Mount Unzen to Mount Shinmoe in Miyazaki prefecture, to guard against the risk of landslides. Whether the threat is from the sea or the mountains, Kobe Steel technology is there to protect people.

"Mobile power plants" help restore damaged infrastructure

![]()

vehicle via helicopter

From the Great Hanshin-Awaji Earthquake and the Chuetsu Earthquake to torrential rains on Amami Oshima, one particular Kobe Steel Group technology has helped to restore infrastructure damaged by natural disasters. Subsidiary Shinko Engineering Co. Ltd. has developed Japan's first mobile power-supply vehicle. These "mobile power plants," which feature a diesel generator mounted on a truck, have helped restore communication and power infrastructure after disasters, by providing backup power sources for NTT base stations or power companies for instance. The same technology played a key role following the Great East Japan Earthquake, too.

To restore its communication network after the Great East Japan Earthquake, the NTT Group needed to mobilize a full fleet of around 400 power-supply vehicles. In response to this request from NTT Facilities, Inc., Shinko Engineering sent out a total of 72 engineers to operate, maintain and manage the vehicles. They worked round the clock for roughly two months, providing support services to get the communication network, which was essential to relief efforts, back up and running. Shinko Engineering has since received a letter of commendation from NTT Facilities, thanking the company for its recovery support services.

Our innovative "Only One" technologies enable us to develop disaster prevention and recovery support technologies such as these. We will continue to protect people through monozukuri across a wide range of areas.

General Manager, Steel Structures

& Sabo Department

Natural Resources & Engineering

Business

These days, we seem to be facing adverse weather conditions and natural disasters such as earthquakes and tsunamis on an ever-increasing scale. We want to do our bit to minimize the damage caused by these disasters, by installing more flared seawalls in coastal towns around Japan. We're really determined to achieve that.

Here at Kobe Steel, we have developed technology to simulate high tides and tsunamis, so that we can design flared seawalls that will offer the best possible protection from waves based on the characteristics of each coastline. It's essentially tailor-made disaster prevention technology. We want to help prevent disasters in the future, by equipping communities throughout Japan to cope with high tides and tsunamis.

Creating Energy Through Monozukuri

![]()

Saving power and reducing environmental impact by using discarded energy sources

At the Kobe Steel Group, we have continued to develop technologies that harness untapped energy sources such as geothermal heat and steam. As a result, we have developed products that "create energy" in the form of electricity or gas. Now that we need to save power and reduce CO2 emissions more than ever, technologies capable of filling in the gaps are crossing over into the mainstream.

Creating power from hot springs, the quintessential Japanese renewable energy source

![]()

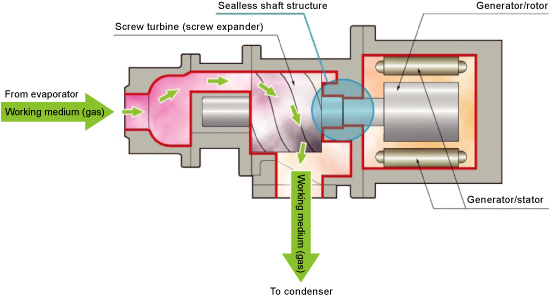

As a volcanic country, there is renewable geothermal energy available throughout Japan. At Kobe Steel, we have developed a compact binary generation system, called Microbinary, to generate power from hot springs. Binary generation is the process of heating and vaporizing a working medium with a low boiling point in hot water at around 70 to 95˚C, and then using the resulting steam to turn a turbine. Systems aren't limited to geothermal heat either. They can generate power using hot water from biomass boilers for instance, or industrial wastewater and steam. This is technology that generates power from untapped energy sources that were previously discarded.

Kobe Steel's world-leading screw compressor technology played a key role in the development of Microbinary, which is the first binary generation system in the world to use a semi-hermetic screw turbine. This makes it possible to generate power efficiently without worrying about fluctuations in the heat source. With no leakage of the working medium, Microbinary can generate up to 60kW of power. That is equivalent to the amount of electricity used by roughly 150 households.

Semi-hermetic screw turbine

First binary generator to start up at hot spring resort in Kyushu

![]()

at Yufuin Shoya no Yakata

(due to start up in December 2012)

In fall 2012, a Microbinary system is due to be installed at Yufuin Shoya no Yakata, a hot spring hotel in the resort of Yufuin in Oita Prefecture. The inn itself has a natural spring that brings up hot water and steam from a depth of approximately 700m, so it will be able to make good use of the hot spring energy to generate power. All of the power generated by the system will be sold via a fixed price purchasing scheme for renewable energy, which is scheduled to come into effect in July 2012.

We plan to keep on reducing the size of our binary generation systems and improve their performance, so that more hot springs, factories and other facilities all over Japan will be able to use this technology.. As these systems can generate power in an emergency, we also envision them being used at disaster prevention facilities run by local authorities.

Steam-powered generators save power and reduce CO2 emissions at plants in Japan

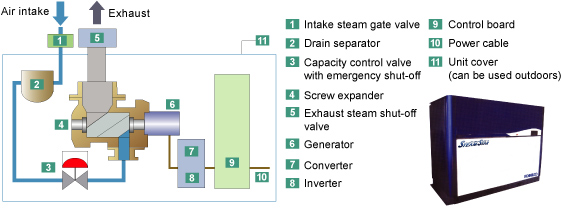

![]()

Another of our technologies that effectively harnesses steam as an untapped energy source is SteamStar®, a compact steam-powered screw-type generator developed by the Kobe Steel Group. Small and medium-scale manufacturing facilities that use compact boilers have struggled to fully utilize the steam produced during the manufacturing process, in the form of decompression energy for instance. With SteamStar however, it is possible to harness such untapped steam energy and generate electricity very efficiently.

There are approximately 250,000 compact boilers in operation around Japan. If just 5% of facilities with such boilers installed SteamStar generators, it would save power and reduce CO2 emissions by an estimated 5 million tons a year.

Basic configuration of SteamStar®

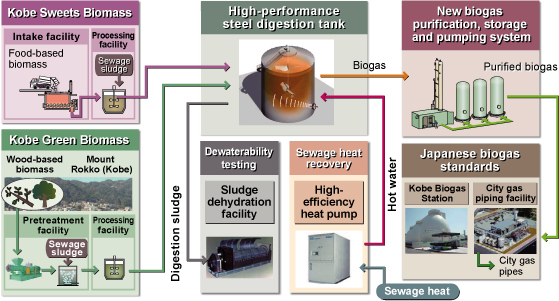

Using biogas to make vehicle fuel and city gas

![]()

Gas is a major source of energy that supports our modern society along with electricity. The Kobe Steel Group is constantly taking on new challenges in the gas sector, too.

In conjunction with Osaka Gas Co. Ltd., Kobelco Eco-Solutions Co. Ltd. and the City of Kobe submitted a proposal to the Ministry of Land, Infrastructure and Transport's B-DASH Project (Breakthrough by Dynamic Approach in Sewage High Technology)*. The government approved the proposal, called the Kobe Green/Sweets Project. The trial project comprises the production of renewable energy and use of innovative technology at Higashinada Sewage Treatment Plant. Kobelco Eco-Solutions is now carrying out research on commission from the National Institute for Land and Infrastructure Management.

The City of Kobe's Higashinada Sewage Treatment Plant already purifies biogas from sewage for use as vehicle fuel or city gas, as part of a cutting-edge initiative that was the first of its kind in Japan.

The aim of the current project is to turn the sewage treatment plant into a supply source for renewable energy. As well as taking in biomass from food ("sweets"), which is well suited to sewage, and wood ("green") to produce more biogas, the project will demonstrate that it is possible to reduce life cycle costs (LCC) and monitor operational status via a steel digestion tank fitted with sensors. The project aims to reduce LCC further by using a heat pump to heat the digestion tank and building in a bio-natural gas conversion system. The future of biogas starts now.

Harnessing untapped energy sources to create electricity and utilizing local biomass to produce gas, we will continue to draw on the Kobe Steel Group's technical capabilities to provide solutions to modern-day issues.

Outline of trial projects

* The Breakthrough by Dynamic Approach in Sewage High Technology (B-DASH) Project is a government scheme that aims to promote innovative technologies that will significantly reduce greenhouse gas emissions and construction costs, in order to treat sewage and reuse sewage sludge for energy more efficiently. This includes setting up and operating actual-scale plants, formulating guidelines and encouraging sewage treatment plants all over Japan to install new technologies

Harnessing our unique technologies to help generate and save energy

Manager, Sales Section

Refrigeration System & Energy Department,

Compressor Division, Machinery Business

Solar and wind power, which are major renewable energy sources, pose problems in terms of maintaining consistent output. Geothermal heat on the other hand is a promising energy source that could potentially generate consistent levels of power from Japan's unique resources as a volcanic country. We are determined to continue promoting binary generation, so that we can make more effective use of resources such as geothermal heat and hot springs.

Now more than ever, we are committed to both creating energy, from geothermal heat and other renewable energy sources, and saving energy, by harnessing untapped energy sources.