Home > About Us > Sustainability Management > Sustainability Report > Sustainability Report 2012 > Promoting Recycling

Promoting Recycling

Promoting Recycling

As our operations cover a wide field, including materials and industrial machinery, we strive to keep waste to an absolute minimum at each of our locations. We also make every effort to reuse and recycle byproducts from our manufacturing processes, so as to make the best possible use of the limited resources we have available.

Curbing Waste Generation and Promoting Recycling

![]()

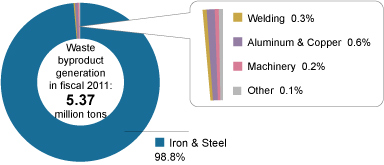

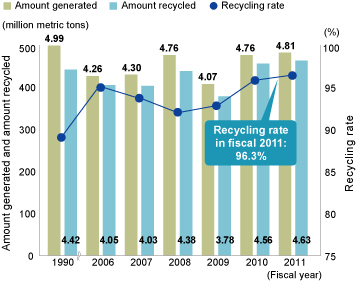

In fiscal 2011, the Kobe Steel Group generated 5.37 million metric tons of byproducts (waste), 98.8% of which was produced as part of our Iron & Steel Business. We have continued to promote efforts to recycle iron and steel slag*, dust and other byproducts generated at our works as a result of the steelmaking process. In fiscal 2011, our recycling rate came to 96.3% for all Kobe Steel plants, and 95.9% for the entire Group.

We have been focusing in particular on reducing the volume of waste sent to landfill during fiscal 2011, by making effective use of slag, dust and other such materials. We have also been making a concerted effort to reduce the volume of waste that we generate in the first place, for instance by optimizing the quantities of raw and auxiliary materials that we use.

The Kobe Steel Group sent around 170,000 tons of waste to landfill overall, representing a 20% reduction compared to the previous year.

We will continue to take steps to reduce the volume of waste generated in the future. We will also undertake resource recovery and develop new recycling technologies. In thse ways, we aim to reduce the volume of waste sent to landfill and achieve our voluntary action plan target by fiscal 2015.

* Slag: Byproduct separated and recovered from molten iron and steel during the refining process

Byproducts Generated by Business Segment (including group companies)

Byproducts Generated by Business Segment (including group companies)

Amount of Waste Byproduct Generated, Amount Recycled & Recycling Rate (parent only)

Amount of Waste Byproduct Generated, Amount Recycled & Recycling Rate (parent only)

Promoting Recycling Activities

![]()

We have drawn up action programs for all of our businesses and at all of our sites, in an effort to reduce the volume of waste sent to landfill. We are continuing to focus on priorities such as reducing and reusing waste, developing recycling technologies, exploring new uses for recycled materials.

Iron & Steel Business

![]()

Recycling Byproducts

![]()

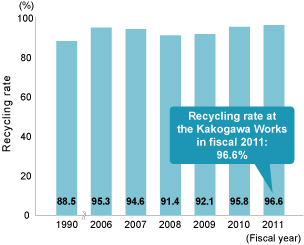

Having continued to develop slag and dust recycling technologies and explore new uses for recycled materials at our Kobe, Kakogawa and Takasago works, we managed to reduce the volume of waste sent to landfill in fiscal 2011 by approximately 30,000 tons compared to the previous year.

Built in partnership with Nippon Steel Corporation, our new steel dust recycling plant (located at Nippon Steel’s Hirohata Works, completed and operational in October 2011) is a prime example of our efforts to recycle byproducts.

By processing around 20,000 tons of steel dust generated by our Kobe Works and Kakogawa Works, this plant has effectively reduced the amount of waste that we send to landfill*.

We intend to make the most of this plant in the future to increase our recycling rate even further.

* More details are in "Contributing to the environment through products, technologies and services."

Recycling Rate at the Kakogawa Works

Recycling Rate at the Kakogawa Works

Recycling iron and steel slag

![]()

In fiscal 2011, our Kakogawa Works and Kobe Works together generated 2.41 million metric tons of blast furnace slag and 1.11 million metric tons of steel slag as byproducts. Both types of slag are reused as a raw material for cement or as a bedding material in road construction. Compared with regular cement, blast furnace cement containing finely powdered blast furnace slag can limit the alkali-aggregate reaction. As it also requires less energy consumption during cement production and reduces emissions of CO2, it is popular in the market. Fine aggregate for concrete made of granulated blast furnace slag helps conserve natural resources as a substitute for natural sand.

By contrast, steelmaking slag can expand in volume owing to its free lime content, and so is used as a road bedding material after expansion has been stabilized through an accelerated aging process that uses steam. Steam aging facilities consist of a concrete pit into which the slag is dumped. The steam is then driven through the slag from the pit floor. Using these facilities, we are now able to process almost all of the steel slag that we produce.

Developing artificial reefs using steel slag

![]()

In an effort to reuse steel slag, one of the byproducts from the steelmaking process, to help restore and protect the environment, we have installed complex steel artificial reefs for seaweed and fish in the Ieshima Islands (off the coast of Himeji, Hyogo prefecture), on the north embankment of Kobe Airport, and in Yonabaru in Okinawa Prefecture. This work was dones in conjunction with Shinko Slag Products, Co. Ltd., Shinko Kenzai, Ltd. and Kobelco Research Institute, Inc. We are also conducting research aimed at nurturing seaweed and improving fishing grounds, as part of a public-private sector project.

Iron, minerals and other nutrients contained within steel slag are anticipated to have restorative effects on marine environments, including helping seaweed to flourish.

The reefs are already covered with seaweed and are attracting migrating fish as the gradual process of restoration gets underway.

A steel artificial reef for seaweed and fish

Migrating fish swimming around one of the reefs

Seaweed growing on one of the reefs

Aluminum & Copper Business

![]()

In the Aluminum & Copper Business, we are working to effectively reuse waste products through CCI&GO (Cost, Cash Innovation/Global & Only One) activities aimed at cutting costs and generating cash.

These activities are already having a major impact, as a result of clarifying the cost of waste products and sharing information on successful initiatives between sites. The three key elements of our CCI&GO activities are as follows:

- Tackling common issues affecting the entire business

- Identifying and combining the most successful initiatives, based on the amount of waste generated and processed, in order to establish the best possible processes

- Assessing waste production costs and working to reduce volumes of high-value items

Specific initiatives include installing wastewater treatment plants, sludge drying facilities, and vacuum distillation facilities to reduce the volume of waste that requires processing and recycling materials so they can be used for other purposes. We are also actively sharing information on related technologies between sites.

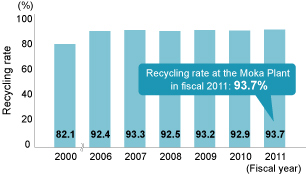

At our Moka Plant, we have been working to reduce the volume of waste sent to landfill by installing wastewater treatment and sludge drying facilities. As a result, we managed to achieve a recycling rate of 93.7% for fiscal 2011.

We are currently continuing with CCI&GO activities, given that they have enabled us to cut annual costs by over ¥100 million across the Aluminum & Copper Business as a whole.

Recycling Rate at the Moka Plant

Recycling Rate at the Moka Plant

Welding Business

![]()

In the Welding Business, we set waste-related targets and implement a range of measures based on the volume of waste generated at each of our locations. We then share expertise and information acquired through such activities via regular meetings.

In an effort to reduce the volume of waste sent to landfill, we are also working to improve methods of recovering and reusing waste flux and lubricants, which are produced when manufacturing welding materials, and have improved specific production figures as a result.

Machinery Business

![]()

Thanks to our efforts to recycle packaging materials from selected products at our Harima Plant, including shipping products in returnable containers, we have managed to keep the volume of waste set to landfill to zero.

We have also introduced a range of measures aimed at reducing waste and promoting recycling at our Takasago Machinery Center, which manufactures compressors and other industrial machinery. As a result, we achieved a recycling rate of 97.9% for fiscal 2011.

Examples of Activities Aimed at Reducing Waste and the Volume of Waste Sent to Landfill

Examples of Activities Aimed at Reducing Waste and the Volume of Waste Sent to Landfill

| Name of company or manufacturing base |

Location | Example initiatives |

|---|---|---|

| Kakogawa Works | Kakogawa, Hyogo |

Reducing slag containing fluorine Recycling mill sludge, etc. Reducing waste refractories by increasing their life span and recycling refractories into raw materials |

| Kobe Works | Kobe, Hyogo |

Reducing waste refractories by increasing life span of ladles Using steam aging to process steel slag for use in earthworks and as bedding material for roads |

| Takasago Works | Takasago, Hyogo | Continuing to develop technology aimed at reusing steel slag more effectively |

| Fujisawa Plant | Fujisawa, Kanagawa |

Reducing volume of wastewater through dewatering and sludge drying Recycling and outside sales of dry lubricants and abrasive sand |

| Ibaraki Plant | Ibaraki, Osaka | Improving methods of reusing and recovering lubricants |

| Saijo Plant | Higashi-Hiroshima, Hiroshima | Reusing flux and recycling raw material for cement |

| Fukuchiyama Plant | Fukuchiyama, Kyoto | Reprocessing and reusing used dies |

| Moka Plant | Moka, Tochigi | Reducing the volume of wastewater by installing dewatering and sludge-drying facilities |

| Daian Plant | Inabe, Mie |

Selling magnesium chips and waste oil Sorting and recovering waste plastic more effectively by using RPF (refuse, paper and plastic fuel) Reusing waste alkaline fluid from wastewater treatment facility |

| Chofu Works Shinko Fab Tech, Ltd. |

Shimonoseki, Yamaguchi |

Increasing volume of recovered aluminum ingot and copper Outside sales of sludge (containing copper) from wastewater treatment |

| Harima Plant | Kako, Hyogo | Reusing cushioning materials from purchased items when shipping components |

| Kansai Coke and Chemicals Co., Ltd. | Kakogawa, Hyogo |

Recycling sludge from wastewater treatment Reusing refractory bricks, etc. |

| Shinko Wire Company, Ltd. | Amagasaki, Hyogo | Recycling selected sludge |

| Kakogawa, Hyogo | Reviewing methods of regulating surface treatment acid to reduce amount used | |

| Shinko Kobe Power Inc. | Kobe, Hyogo | Optimizing volume of coagulant additives used in wastewater treatment facilities |

| Shinko Special Tube Co., Ltd. | Shimonoseki, Yamaguchi | Reviewing usage of hydrofluoric acid to reduce waste and reuse acid |

| Ceratechno Co,. Ltd. | Bizen, Okayama | Reducing and reusing spilled ore, reusing dust |

| Akashi, Hyogo | Reducing spillages from transport equipment by reinforcing preventive measures | |

| Tesac Wirerope Co., Ltd. | Kaizuka, Osaka | Recycling sludge from wastewater treatment facilities |

| Nippon Koshuha Steel Co., Ltd. | Imizu, Toyama |

Reviewing frequency of acid washing to reduce sludge Melting and reusing dust from electric furnaces |

| Shinko Actec Co., Ltd. | Toyooka, Hyogo | Reusing recovered flux and burrs |

| Hanshin Yosetsu Kizai Co., Ltd. | Okayama, Okayama |

Taking steps to control dust generation Recycling dust into raw materials |

| Niko-Aluminium Industries, Ltd. | Moka, Tochigi | Improving coating processes to reduce volume of coatings used |

| Kobelco & Materials Copper Tube, Ltd. | Hadano, Kanagawa | Outside sales of copper dregs |

| Kobelco Research Institute, Inc. | Takasago, Hyogo |

Reusing refractories Outside sales of metal chips |

| Kobelco Construction Machinery Co., Ltd. | Hiroshima, Hiroshima | Outsides sales of waste oil |

| Ogaki, Gifu | Using specialized returnable containers to reduce waste | |

| Kobelco Cranes Co., Ltd. | Akashi, Hyogo | Using specialized returnable containers to reduce waste |

| Shinko Industrial Co., Ltd. | Kurayoshi, Tottori | Promoting the reuse of more welding slag |

| Shinko Engineering Co., Ltd. | Ogaki, Gifu | Using fracturing facilities to reuse sand |