Home > About Us > Sustainability Management > Sustainability Report > Sustainability Report 2012 > Reducing the Environmental Impact

Reducing the Environmental Impact

Reducing the Environmental Impact

"Reducing the environmental impact from production" is one of the principles outlined in the Kobe Steel Group Basic Environmental Management Policy. As such, we are committed to environmentally friendly manufacturing in every aspect of our activities, including ongoing improvements to production processes, upgrading equipment, using the latest high-efficiency facilities and installing pollution control equipment to deal with environmental pollutants. We make every effort to reduce the environmental impact that our activities place on the air, water and other elements of the environment and will continue to do so at all group companies in the future.

Measures to Counter Atmospheric Pollution

![]()

Air Emissions

![]()

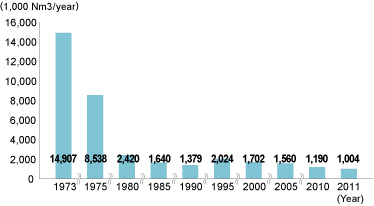

In addition to taking steps to reduce sulfur oxide (SOx) emissions from production processes and other sources through initiatives such as saving energy to reduce fuel consumption, using low sulfur fuels and switching fuels to city gas, we continue to subject emissions to desulfurization treatment and other such measures.

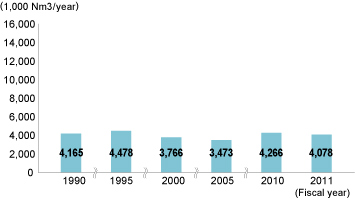

In terms of nitric oxide (NOx), we are focusing on reducing emissions through initiatives such as installing low NOx combustion technology and energy saving measures.

Volume of Sulfur Oxide Emissions (parent only)

Volume of Sulfur Oxide Emissions (parent only)

Volume of Nitric Oxide Emissions (parent only)

Volume of Nitric Oxide Emissions (parent only)

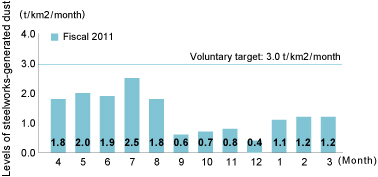

Dust control measures at the Kakogawa Works

![]()

At the Kakogawa Works, we have set ourselves the voluntary target of limiting steelworks-generated dust per square kilometer per month to 3.0 metric tons or less in three locations in the vicinity of the steelworks, and have continued to implement a range of measures to achieve that target.

We managed to keep within our target of 3.0 metric tons per square kilometer per month throughout fiscal 2011.

Levels of Steelworks-generated Dust (recorded at Kakogawa Shinko Building)

Levels of Steelworks-generated Dust (recorded at Kakogawa Shinko Building)

Water Pollution Prevention

![]()

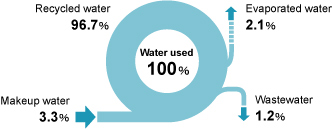

In the Kobe Steel Group, the water consumption rate is being reduced by improving production processes and using recycled water. Wastewater from production processes is purified via treatment systems best suited to the properties of the relevant water so as to reduce the impact of water-polluting substances on public water supplies.

Once wastewater from individual production processes at our steelworks has been purified, using methods such as coagulation sedimentation and sand filtration, it is then reused on-site via our water recycling system. We have achieved a water recycling rate of approximately 96.7% at the Kakogawa Works.

Breakdown of Water Recycling

Breakdown of Water Recycling

Efforts to Reduce Wastewater (Kakogawa Works, fiscal 2011)