Home > About Us > Sustainability Management > Sustainability Report > Sustainability Report 2012 > Contributing to the Environment Through R&D

Contributing to the Environment Through R&D

Contributing to the Environment Through R&D

Contributing to the Environment through Products, Technologies and Services

We are committed to developing environmentally friendly materials and machinery in an effort to create and increase sales of the Kobe Steel Group's "Only One" products. This section outlines some of the research and development activities that underpin our efforts to commercialize environmentally friendly materials.

High heat-transfer titanium sheet

![]()

We are always working to develop new materials that will meet society's needs, in terms of reducing CO2 emissions and cutting energy costs. Heat exchangers are a prime example, as they are able to use seawater as a readily available heating and cooling source. If we can harness the corrosion resistant properties of titanium sheet and improve heat conductivity, heat exchangers are likely to be used for an increasingly wide range of applications in the future.

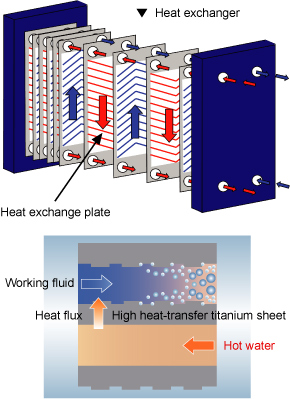

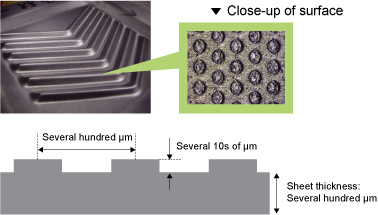

To improve heat conductivity using a regular plate heat exchanger, the user would have to process the heat transfer surface by forming it into a corrugated shape. As an alternative, we opted to improve heat conductivity by making minute bumps on the surface of the titanium sheet itself. This increases the surface area, enhances turbulent heat transfer, and facilitates nucleate boiling (Figure 1). We therefore set about developing the necessary technology to manufacture this type of titanium sheet (Figure 2). Taking into account productivity and manufacturing costs, we decided to used cold rolling for faster processing. Titanium sheet is rolled between two work rolls with uneven surfaces so that the unevenness is transferred onto the sheet. In order to make high enough protrusions of several tens of microns via the rolling process however, it is crucial to get the shape of the protrusions and rolling conditions just right. The rolling technology and process as a whole need to be advanced enough to achieve the right thickness and flatness for the material to be used in products.

Our Technical Development Group carried out testing and made prototypes using a small-scale rolling mill. Having compiled rolling force predictions, based on rolling theory and improved levels of flatness, our researchers managed to produce a viable high heat-transfer titanium sheet.

Using the resulting high heat-transfer titanium sheet is expected to increase heat conductivity by over 10% if using a heat exchanger with a boiling media (Figure 3), making it possible to improve performance without reconfiguring equipment. It is also possible to reduce the number of heat exchange plates made of titanium sheet and the volume of fluid used as a heat source. As a result, it should be possible to streamline equipment, by reducing the level of pump usage required to circulate the fluid, and cut costs.

Practical research, commissioned by the New Energy and Industrial Technology Development Organization (NEDO), is underway into ocean thermal energy conversion (OTEC) generation using high heat-transfer titanium sheet (i.e. generating power using the small difference in temperature of around 20˚C between cold deep water and surface water that has been warmed by the sun). In order to make OTEC generation a commercial reality, we need to develop an inexpensive heat exchanger with a large surface area that is highly resistant to corrosion from seawater (the heat source) and that can efficiently extract energy from such a small difference in temperature. The ideal solution would be to commercialize our high heat-transfer titanium sheet. As part of the aforementioned commissioned research, we are currently conducting trials on high heat-transfer titanium sheet in an effort to increase the efficiency of heat exchangers.

Figure 1. Heat exchanger made from high heat-transfer titanium sheets

Figure 1. Heat exchanger made from high heat-transfer titanium sheets

Figure 2. High heat-transfer titanium sheet

Figure 2. High heat-transfer titanium sheet

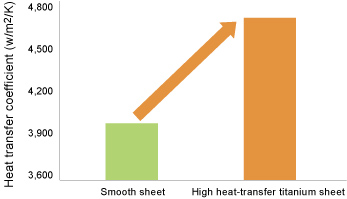

Figure 3. Comparison of heat transfer against a regular sheet

Figure 3. Comparison of heat transfer against a regular sheet