Home > About Us > Sustainability Management > Sustainability Report > Sustainability Report 2012 > Providing outstanding products and services

Providing outstanding products and services

Providing outstanding products and services

To "provide reliable technologies, products and services that satisfy customers," one of the aims set out in the Kobe Steel Group's Corporate Philosophy, we are committed to continually improving our monozukuri-ryoku, or manufacturing strengths, via a comprehensive range of activities covering every stage of the process, from sales and marketing to development and design, to procurement, manufacturing and production. Referring to our ability to continually provide reliable technologies, products and services, our manufacturing capabilities are the driving force behind growth. We are determined to keep on improving our manufacturing capabilities in the future by reinforcing links between individual locations. We will also continue to maintain the trust of our customers and business partners, both in Japan and overseas. Furthermore, we will keep on supplying products and services that satisfy our customers

MONODZUKURI (Production System Innovation) Planning and Promotion Department

![]()

Since its establishment in April 2010, the MONODZUKURI (Production System Innovation) Planning and Promotion Department has been working to improve manufacturing capabilities throughout the Kobe Steel Group, based on the key concepts of cross-deployment between sites and visualization.

In addition to improving technical standards by sharing details of the most successful initiatives within the company, we are also working to establish a set of standard indicators in order to visualize our monozukuri-ryoku, or manufacturing strengths.

If we can enhance our manufacturing strengths on a groupwide basis, by reinforcing technical capabilities, establishing management indicators and rolling out activities to group companies the world over, we will be able to keep on providing our customers with products and services they can trust. That is the sort of system we are aiming to put in place.

Cross-Deployment between Locations

![]()

Basic Policy

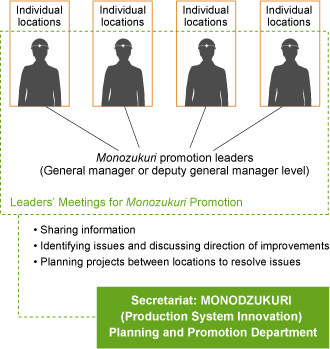

We share general information via leaders' meetings for monozukuri promotion attended by representatives from each location and promote exchanges between a network of engineers specializing in individual technologies via production technology exchange meetings.

Leaders' Meetings for Monozukuri Promotion

![]()

Promotion

Groupwide activities revolve around monozukuri promotion leaders (at the general manager or deputy general manager level) at each of our plants. We then get all leaders together for leaders' meetings for monozukuri promotion three times a year, in order to outline effective initiatives and discuss general matters relating to key policies.

Initiatives outlined during such meetings are then used as guidelines for improvement activities at other sites. We also arrange individual meetings upon request if necessary.

As well as sharing information, in the future we intend to use meetings so that leaders can work together to identify groupwide issues and work out the best direction for improvements

Envisioned companywide organization for monozukuri

Envisioned companywide organization for monozukuri

Production Technology Exchange Meetings

![]()

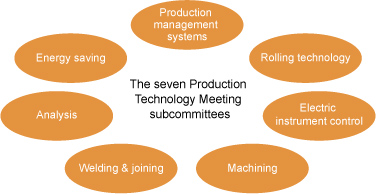

Whereas the purpose of Monozukuri Leaders Meetings is to share manufacturing and related information between sites and discuss possible measures, production technology exchange meetings are intended for engineers specializing in individual key technologies.

The aim is to bring together engineers working on the same technologies or in the same field at different locations to speed up the process of resolving issues, while at the same time helping to train engineers more efficiently.

In an effort to deal with the common issues of "chatter vibration"* in machining for instance, we developed a system that enables us to avoid chatter and configure cutting conditions to achieve optimum production efficiency. Thanks to production technology meetings, we are now able to use this system throughout the group.

Although activities currently revolve around seven subcommittees, we are planning to expand into other areas of technology in the future. Our vision is for groupwide issues identified via leaders' meetings for monozukuri promotion to then be tackled by project teams put together via production technology exchange meetings.

* The phenomenon of "chatter vibration" occurs when cutting tools or the material itself vibrates during the cutting process.

This has a significant impact on precision and can even damage cutting tools in some cases.

The seven Production Technology Meeting subcommittees

The seven Production Technology Meeting subcommittees

Visualization – Establishing groupwide standard indicators

![]()

Basic Policy

We take appropriate steps to evaluate improvement activities in order to clarify issues and improve the manufacturing capabilities of the entire group.

Quality cost control

![]()

The most important consideration when operating any plant is to ensure safety. The next most important consideration is improving quality. (See diagram)

As the first step towards monitoring groupwide quality control standards, the MONOZUKURI (Production System Innovation) Planning and Promotion Department has introduced a precise system based on the universal concept of "quality cost control." As well as rolling out this system to group companies in the future, we are working to visualize our manufacturing capabilities based on various other priorities as well as quality, in order to create a framework that is capable of delivering quality products to customers precisely when they need them.

Order of priority for improvement activities

Order of priority for improvement activities

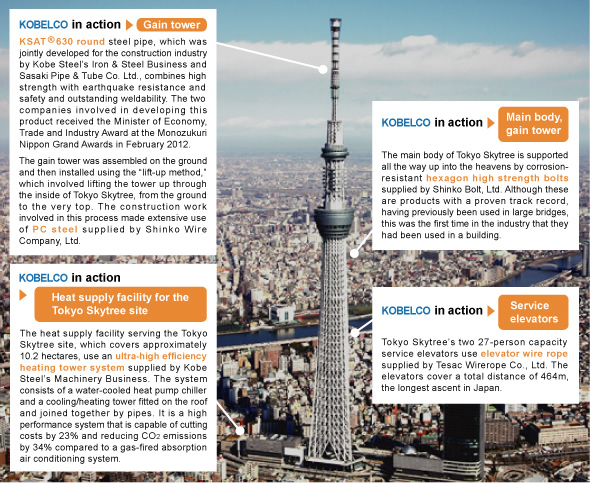

KOBELCO products used in Tokyo Skytree®

![]()

Standing approximately 634 m tall, Tokyo Skytree is the world's tallest freestanding broadcasting tower. It opened for business on May 22, 2012 and has already become a new Japanese landmark. It also uses Kobe Steel Group products at various points.

The purpose of Tokyo Skytree is to broadcast terrestrial digital signals. Concerns that the increasing number of high-rise buildings over 200 m in the central Tokyo area could potentially disrupt radio waves led to calls for a broadcasting tower around the 600 m mark, in order to transmit at a higher altitude.

The crucial component in order to broadcast radio waves is the gain tower. Digital broadcast antennas are attached to the gain tower, which is roughly 160 m long and has a diameter of around 6 m, at the top of Tokyo Skytree. It is made from the highest strength circular steel pipe currently available in Japan, jointly developed for the construction industry by Kobe Steel's Iron & Steel Business and Sasaki Pipe & Tube Co., Ltd. The main body of Tokyo Skytree meanwhile uses welding materials supplied by Kobe Steel's Welding Business, high strength bolts supplied by Shinko Bolt, Ltd. and prestressed concrete (PC) steel supplied by Shinko Wire Company, Ltd.

Located roughly 20 minutes by train from Tokyo Station, and around 30 minutes from Shinagawa Station, be sure to take a look up if you're to Tokyo Skytree on foot. Up there, you will see the Kobe Steel Group's high quality products and technologies in use, 600 m off the ground.

Photo courtesy of Obayashi Corporation

Products used in Tokyo Skytree

Products used in Tokyo Skytree

|

Company / |

Location |

Product |

Volume |

|---|---|---|---|

| Kobe Steel's Iron & Steel Business, Sasaki Pipe & Tube Co., Ltd. |

Main body |

Round steel pipe Steel plate for use in steel frame |

5,000t 1,000t |

|

Gain tower |

Round steel pipe Steel plate for use in steel frame |

750t 200t |

|

|

Lower floors, central part of tower, viewing platform |

Steel plate for use in steel frame |

2,400t |

|

| Shinko Bolt, Ltd. |

Main body |

Torshear high strength bolts Corrosion-resistant hexagon high strength bolts |

235t |

|

Gain tower |

Corrosion-resistant hexagon high strength bolts |

15t |

|

| Shinko Wire Company, Ltd. |

Construction work involved in lifting up gain tower |

15.2 mm diameter PC steel |

148t |

|

Concrete reinforcement of central pillar |

15.2 mm diameter PC steel |

283t |

|

|

Construction work involved in lifting up emergency stairs |

15.2 mm diameter PC steel |

2t |

|

| Tesac Wirerope Co., Ltd. |

27-person capacity service elevators |

Wire rope for single-deck elevator |

33t |

| Kobe Steel's Welding Business |

Main body, gain tower |

Flux-cored wires, solid wires, submerged wires |

100t |

| Kobe Steel's Machinery Business |

Heat supply facility for Tokyo Skytree site |

Water-cooled heat pump chiller for ultra-high efficiency heating tower system (KHT Series) |

12units |