Home > About Us > Sustainability Management > Sustainability Report > Sustainability Report 2013 > Material Balance

Material Balance

Material Balance

The Kobe Steel Group undertakes environmentally conscious management throughout every aspect of its operations.

As part of this approach, the Group continuously strives to increase energy efficiency, make effective use of byproduct gases, waste heat, water and other resources, and promote the recycling of byproducts.

Resource and Energy Usage at Kobe Steel

![]()

Iron & Steel Business

![]()

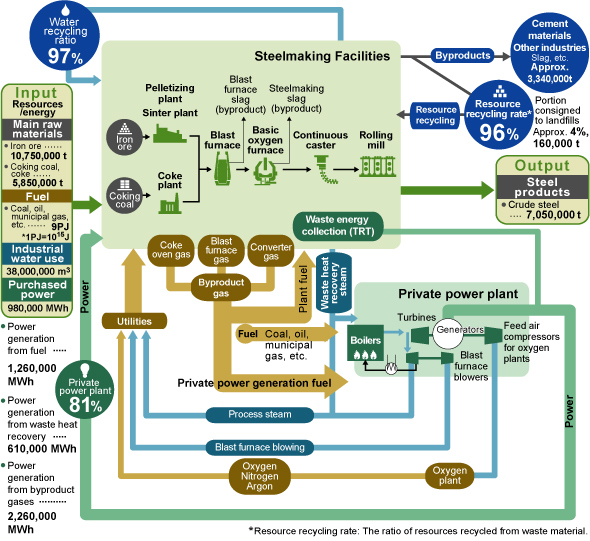

At Kobe Steel, 95% of the energy usage is in the Iron & Steel Business. In fiscal 2012, this business unit used 10.75 million tons of iron ore, 5.85 million tons of coking coal and coke, 9PJ1 of fuels such as coal, oil and municipal gas, and 980,000 MWh of purchased power. Nearly all of the byproduct gases -- including coke oven gas, blast furnace gas and converter gas – derived from production processes are effectively reused as fuel for reheating steel or for use in inhouse generators. Kobe Steel also proactively implements power generation that utilizes waste heat. Combined with the power generated from byproduct gases, over 50% of the power required by production processes is generated through energy recovery.

Additionally, byproducts produced during production processes, such as slag2, dust and sludge, are also turned to effective use as raw materials in applications such as cement and roadbeds. Together with in-company re-use, 96% of byproducts are recycled in this manner.

In the future, Kobe Steel will continue to pursue environmentally friendly practices throughout all aspects of its operations, striving for more efficient use of resources and energy and advancing the development of new technologies to that end.

1. 1PJ=1015J

2. Slag is a byproduct recovered from ironmaking and steelmaking.

Resource and Energy Usage in the Iron & Steel Business (Fiscal 2012)

Welding Business

![]()

Using metal wires, hoops, fluxes, soluble glass and other raw materials, the Welding Business produces welding electrodes and welding wires. In fiscal 2012 the Fujisawa, Ibaraki, Saijo and Fukuchiyama plants used a combined 180,000 tons of raw materials, 66,000 MWh of electricity, and 0.2PJ of municipal gas and other fuels to manufacture 170,000 tons worth of products. This generated 16,000 tons of byproducts, of which 97% was successfully recycled.

Resource and Energy Usage in the Welding Business (Fiscal 2012)

| Input | Output | |||

|---|---|---|---|---|

| Raw materials | Products | |||

| Metal wires, hoops, flux, soluble glass, etc. |

180,000 t | Welding rods, welding wires, etc. | 170,000 t | |

| Energy | Waste materials | |||

| Purchased power | 66,000 MWh | Amount produced | 16,000 t | |

| Municipal gas, etc. | 0.2PJ | Recycling ratio* | 97% | |

* Recycling ratio indicates the ratio of waste produced that is not consigned to landfills.

Aluminum & Copper Business

![]()

Using ingots and scrap metal as raw materials, the Aluminum & Copper Business produces a variety of aluminum and copper products. In fiscal 2012 the business unit used 350,000 tons of raw materials, 430,000 MWh of electricity, and 3.3PJ of municipal gas and other fuels to create 320,000 tons of products.

During melting and casting, 26,000 tons of waste products, such as slag, dust and wastewater sludge, were produced. However, 97% of this waste was successfully recycled.

Resource and Energy Usage in the Aluminum & Copper Business (Fiscal 2012)

| Input | Output | |||

|---|---|---|---|---|

| Raw materials | Products | |||

| Aluminum ingots, copper ingots, etc. | 350,000 t | Aluminum and copper products | 320,000 t | |

| Energy | Waste materials | |||

| Purchased power | 430,000 MWh | Amount produced | 26,000 t | |

| Municipal gas, etc. | 3.3PJ | Recycling ratio* | 97% | |