Home > About Us > Sustainability Management > Sustainability Report > Sustainability Report 2013 > Reducing the Environmental Impact

Reducing the Environmental Impact

Reducing the Environmental Impact

As part of its Basic Environmental Management Policy, the Kobe Steel Group is committed to "environmentally friendly manufacturing," and pursues this commitment on a variety of fronts, including improvements to sustainable manufacturing processes, updates to equipment, the introduction of efficient state-of-the-art equipment, and the introduction of pollution control equipment. The Group is striving to reduce its environmental impact on the atmosphere and water. In the future, Kobe Steel and its group companies will continue to reduce their impact on the environment even further.

Air Pollution Measures

![]()

Air Emissions

![]()

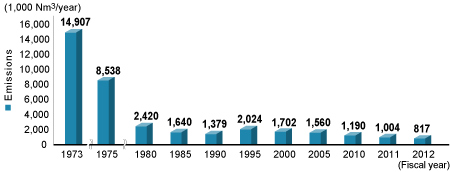

To suppress SOx (sulphur oxide) in manufacturing processes, we implement desulphurization and other exhaust emission controls as well as control emissions by reducing fuel consumption and switching to city gas.

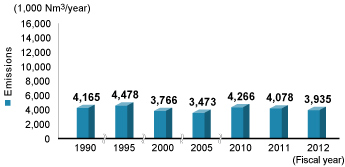

Likewise, in order to reduce NOx (nitrogen oxide) emissions, we also implement efforts such as the use of low NOx combustion technology and energy-saving measures.

SOx Emissions (Kobe Steel)

NOx Emissions (Kobe Steel)

Measures to Counter Dust at the Kakogawa Works

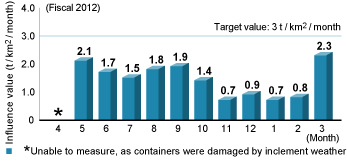

![]()

At the Kakogawa Works, voluntary targets for dustfall in three neighboring locations have been set at less than 3 tons/km2/month. In fiscal 2012, targets were met throughout the year due to countermeasures introduced such as those to limit dust from belt conveyors*.

*Debris can cling to the belt conveyors used to transport ore. When this debris comes loose it can result in dust. To prevent this, mechanical cleaners were installed on belts with a large amount of debris so as to wash their surfaces.

Steelworks Influence Values (Kakogawa Shinko Building)

Water Pollution Measures

![]()

Water Recycling

Emission Reduction Initiatives

(e.g. Kakogawa Works, fiscal 2012)

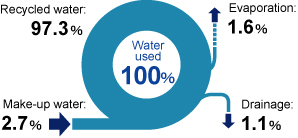

The Kobe Steel Group reduces water consumption through measures such as improvements to manufacturing processes and wastewater recycling. Additionally, drainage from manufacturing processes is purified using specialized treatment systems in order to reduce the impact on public waters.

Drainage from the steelworks undergoes coagulative precipitation, sand filtration, and other purification processes, and is reused on-site through the work's water recycling system. As a result, a 97.3% water recycling rate is achieved at the Kakogawa Works and Kobe Works.