Home > About Us > Sustainability Management > Sustainability Report > Sustainability Report 2013 > Environmental Accounting

Environmental Accounting

Environmental Accounting

The Kobe Steel Group continuously engages in environmental conservation. The cost and benefit of these efforts is analyzed, and relevant information is disclosed in order to deepen understanding on the part of stakeholders.

Environment-Related Investments

![]()

Capital is invested for the introduction and continual maintenance of environmentally sound facilities, and environmental measures are pursued on a variety of fronts. Capital investments in fiscal 2012 were approximately ¥3.06 billion, while expenses were approximately ¥37.88 billion. Approximately 33% of expenses was used to limit air pollution, approximately 13% to limit water pollution, and approximately 33% for resource recycling.

Additionally, in order to contribute to the environment via products, technologies and services, development of hydrogen station technologies and binary power generation systems was carried out. Expenses for product and technology developments such as these accounted for approximately 15% of total expenses, at approximately ¥5.69 billion.

Breakdown of Capital Investments and Expenses

(100,000,000 yen)

| Category | Capital investments | Expenses | |||

|---|---|---|---|---|---|

| Within business area | Pollution control | Air pollution control |

9.2 |

124.0 |

|

| Water pollution control |

0.8 |

49.2 |

|||

| Resource recycling | Waste recycling/treatment |

8.0 |

124.8 |

||

| Environmental conservation | Investment in energy conservation |

12.6 |

- |

||

| Management activity | EMS registration, updates, etc. |

- |

0.1 |

||

| Inspection of environmental impact |

- |

2.8 |

|||

| Environmental organization personnel |

- |

17.4 |

|||

| Research and development | Developments for the reduction of environmental burden through eco products/manufacturing processes |

- |

56.9 |

||

| Social activity | Support for environmental organizations, PR, etc. |

- |

0.3 |

||

| Other | Pollution load levies |

- |

3.3 |

||

| Total |

30.6 |

378.8 |

|||

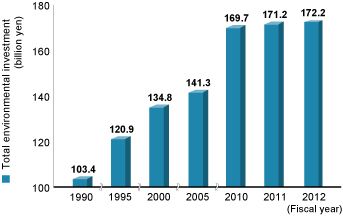

Total Environmental Investment (Kobe Steel)

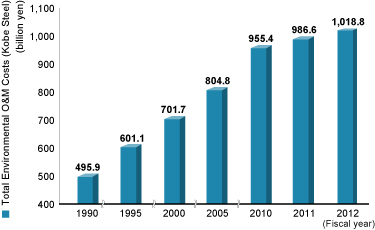

Total Environmental O&M Costs (Kobe Steel)

*The above two graphs are for cumulative totals from fiscal 1970.

Results of Environmental Conservation

![]()

In fiscal 2012, Kobe Steel implemented the following initiatives in regard to environmental conservation:

Kakogawa Works

Kakogawa Works

Belt conveyor dust measures (air pollution control) Ibaraki Plant

Ibaraki Plant

Updates to emergency holding tanks for drainage (water pollution control) Fukuchiyama Plant

Fukuchiyama Plant

Updates to plating solution leakage alarms (water pollution control)

In the future, Kobe Steel plans to continue implementing updates to equipment and other environmental conservation measures.