Home > About Us > Sustainability Management > Sustainability Report > Sustainability Report 2013 > Contributing to Lighter Automobiles

Contributing to Lighter Automobiles

Contributing to Lighter Automobiles

In order to promote environmental conservation, new regulations on automobile exhaust emissions are being developed in countries throughout the world. Accordingly, in order to improve fuel consumption and reduce CO2 emissions, the need for lightweight materials has been growing among automobile manufacturers. Utilizing the advanced technologies accumulated over our many years as a comprehensive producer of materials, Kobe Steel has created a broad range of differentiated products that contribute to lightweighting and strengthen our worldwide presence in the automobile market.

Symbols indicate the sectors in which our products are used by customers.

![]()

Contributing through Steel Products

Contributing through Steel Products

![]()

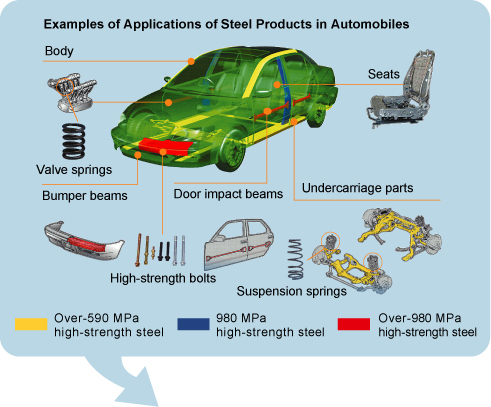

Responding to the need for added value in the automobile and consumer electronics fields, Kobe Steel produces materials such as high-strength steel sheet, surface-treated steel sheet, precoated steel sheet, and environmentally friendly ZINKOBELLA GREENCOTE steel sheet, which is free of hexavalent/trivalent chromium. In particular, we have been involved in the research and development of high-strength steel sheet from its earliest days. Through supplying distinctive "Only One" products such as steel for bolts and valve springs, we have built a reputation among automobile manufacturers for our contributions to lighter, safer and more environmentally friendly cars.

The Evolution of High-Strength Steel Sheet

![]()

Utilizing the know-how for composition, microstructure control through heat treatment, and other processes amassed through our specialization in the field of special steels for wire rods and bars, Kobe Steel continues to improve its high-strength steel sheet. Combining high strength with exceptional formability, the steel is used in a wide variety of functional components such as automobile bodies, bumpers and door impact beams, as well as parts for seats and other applications that require complex processing

Joining of Dissimilar Metals Aluminum Alloy and Steel Contributes to Lighter Cars

Joining of Dissimilar Metals Aluminum Alloy and Steel Contributes to Lighter Cars

![]()

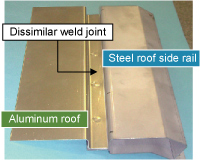

Kobe Steel is developing highly productive methods to weld dissimilar metals during automobile assembly. Through material qualities conducive to welding and control of welding conditions, a bond equal in strength to the welding of aluminum to aluminum can be achieved.

Through further developments combining steel and aluminum technologies, Kobe Steel will continue to contribute to automobile lightweighting.

Contributing through Aluminum Products

Contributing through Aluminum Products

![]()

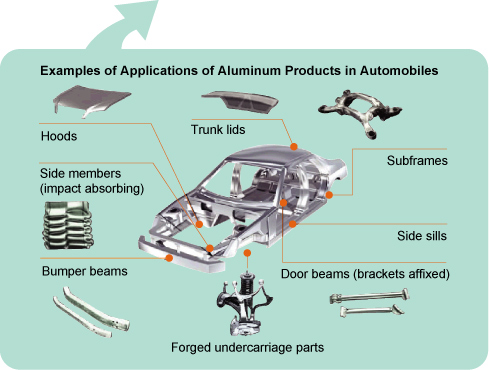

In order to reduce CO2 emissions through lighter weight automobiles, Kobe Steel is developing aluminum products for a variety of automobile parts. These include effective hoods, panel materials such as for doors, extrusions such as for bumpers, and forgings for undercarriage parts such as for suspensions. The development of such parts allows us to contribute to more fuel efficient cars.

With a diversity of high-precision, high-quality casting and forging technologies accumulated from the manufacture of aircraft parts, Kobe Steel is able to meet a variety of needs for aluminum cast and aluminum forged products.

Integrated Manufacturing of Aluminum Forgings for Automobile Suspensions in Three Countries

![]()

From melting and casting to forging, the production of our aluminum forged parts for automobile suspensions relies on integrated production in three countries. Production takes place at the Daian Plant in Japan, Kobe Aluminum Automotive Products, LLC in the United States, and Kobe Aluminum Automotive Products (China) Co., Ltd. in China.