Home > About Us > Sustainability Management > Sustainability Report > Sustainability Report 2013 > Unparalleled Products and Services

Unparalleled Products and Services

Unparalleled Products and Services

We are committed to continually improving our monozukuri-ryoku, or manufacturing capabilities, through a comprehensive range of activities covering all of our operations, including sales and marketing, development and design, procurement, and manufacturing and production, in order to "provide reliable technologies, products, and services," which is an aim set out in the Kobe Steel Group's Corporate Philosophy. "Manufacturing capabilities" refers to our ability to continually provide reliable technologies, products, and services, which are the engines of growth. We are determined to keep on improving our manufacturing capabilities by enhancing links between our locations, in order to maintain the trust of our customers and business partners, both in and outside Japan, and to keep on supplying products and services that satisfy our customers.

MONODZUKURI (Production System Innovation) Planning and Promotion Department

![]()

Since its establishment in April 2010, the MONODZUKURI (Production System Innovation) Planning and Promotion Department has been working to improve manufacturing capabilities throughout the Kobe Steel Group, based on the key concepts of cross-deployment of manufacturing-related information between sites and visualization of manufacturing capabilities.

In addition to improving technical standards by sharing details of the best practices within the Group, we are also working to establish a set of standard indicators to visualize our manufacturing capabilities.

Going forward we will continue raising the level of our manufacturing capabilities throughout the Group by reinforcing technical competence, establishing management indicators, and rolling out activities to group companies the world over, with the aim of putting in place systems that will enable us to keep on providing our customers with products and services they can trust.

Cross-Deployment between Locations

![]()

Basic Policy

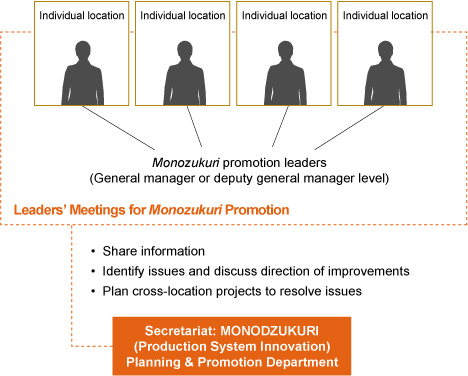

We share general information through leaders' meetings for monozukuri promotion attended by representatives from each location and also promote exchanges through production technology exchange meetings for networks of engineers specialized in individual elemental technologies.

Leaders' Meetings for Monozukuri Promotion

![]()

-

Each location in the Group has a monozukuri promotion leader (at the general manager or deputy general manager level) who acts as a conduit for groupwide activities. We get all leaders together for leaders' meetings for monozukuri promotion, at which we outline best practices and discuss general matters relating to key policies.

Initiatives outlined during these meetings are then used as guidelines for improvement activities at other locations. We also arrange individual meetings upon request if necessary.

As well as sharing information, in the future we intend to use these meetings so that leaders can work together to identify groupwide issues and work out the best direction for improvements.

-

Leaders' meetings for

monozukuri promotion

Envisioned Companywide Organization for Monozukuri

Production Technology Exchange Meetings

![]()

Whereas the purpose of monozukuri leaders meetings is to share manufacturing-related information between sites and discuss various measures, production technology exchange meetings are intended for engineers specializing in individual elemental technologies.

The aim is to bring together engineers working on the same technologies or in the same field at different sites to speed up the process of resolving issues, while at the same time helping to train engineers more efficiently.

The Energy-Saving Subcommittee, for example, created a team of experts who were scattered thorough the Group to propose improvements for making energy savings while visiting individual sites. The new insights being added to improvement work that individual sites used to attempt on their own are starting to lead to the development of more effective improvement proposals.

Although activities in production technology exchange meetings currently revolve around seven subcommittees, we are planning to expand into other areas of technology in the future. Our vision is for groupwide issues identified in leaders' meetings for monozukuri promotion to then be tackled by project teams put together at production technology exchange meetings.

The Seven Subcommittees of Production Technology Exchange Meetings

Establishing Groupwide Standard Indicators

![]()

Basic Policy

We evaluate improvement activities appropriately in order to clarify issues and improve the manufacturing capabilities of the entire group.

Quality Cost Control

![]()

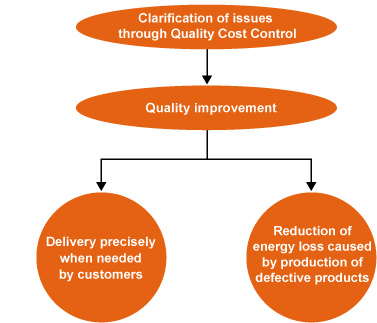

The most important consideration when operating any plant is to ensure safety. The next most important consideration is improving quality. (See diagram)

The MONODZUKURI (Production System Innovation) Planning and Promotion Department has introduced Quality Cost Control* as an indicator for monitoring the status of groupwide quality control as a first step followed by improvement efforts. Quality improvement activities are also effective for reducing energy usage in product manufacturing.

We will continue pursuing further quality improvements in the future and will create a framework that is capable of delivering products of a quality that satisfies customers-to customers precisely when they need them.

* Quality Cost Control: A management approach for evaluating quality control and quality improvement activities using cost as a shared indicator. The objective is to clarify issues and the effects of improvement measures.

Order of Priority for Improvement Activities

Ripple Effect of Quality Improvement