Home > About Us > Sustainability Management > Sustainability Report > Sustainability Report 2013 > Disaster Prevention Initiatives

Disaster Prevention Initiatives

Disaster Prevention Initiatives

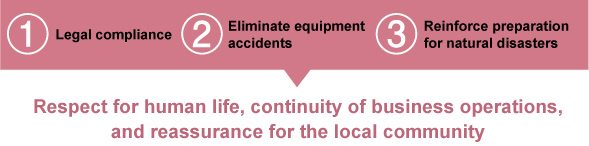

The Kobe Steel Group makes groupwide efforts to comply with laws and regulations, implement measures to guard against equipment accidents, and prepare for natural disasters through such means as establishing disaster management systems and holding regular training exercises. These measures are actively pursued to prevent accidents from occurring and to minimize damage if a disaster does strike.

We will continue to raise each and every employee's awareness of disaster prevention while continuing to carry out disaster prevention activities on a groupwide basis.

Fiscal 2012 Companywide Disaster Prevention Management Policy

![]()

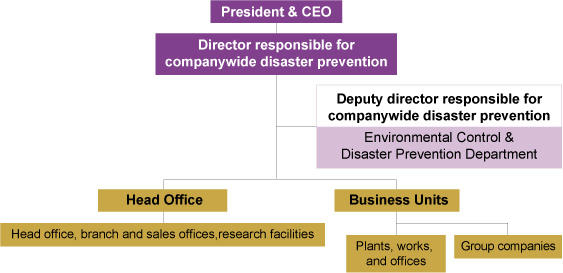

Companywide Disaster Prevention Management Structure

![]()

At Kobe Steel we believe that health and safety are fundamental to business management and take priority over all business activities. In keeping with this principle, we take various steps to create a vital workplace where employees can safely pursue their careers with peace of mind.

Companywide Disaster Prevention Management Structure

Disaster Management Structure

![]()

In the event of a large-scale earthquake or other natural disaster or accident we will set up a disaster management headquarters at our Tokyo Head Office or Kobe Head Office to coordinate relief efforts and restoration activities.

When the Great East Japan Earthquake struck, we established a headquarters at our Tokyo Head Office to verify people’s safety and provide assistance for affected locations. We also provided support to get operations up and running again as quickly as possible, including coordinating and shipping relief supplies.

We intend to continue our educational and training activities in the future to ensure that we can respond to any disaster as smoothly as possible.

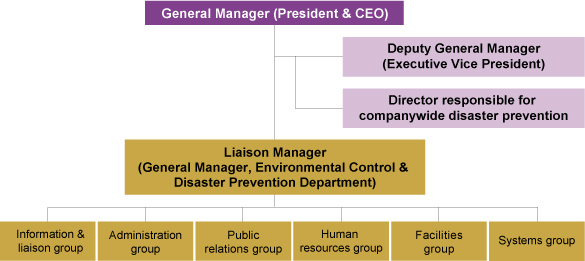

Disaster Management Headquarters Organization

Kobe Steel Group Disaster Prevention Meeting

![]()

Group Disaster Prevention

Meeting

We organize the Kobe Steel Group Disaster Prevention Meeting every year in an effort to share information and strengthen disaster prevention initiatives. A total of 74 employees from 29 Group companies took part in our fiscal 2012 meeting, which featured updates on the latest revisions to laws and regulations, reports on initiatives at individual locations, and a special lecture by Professor Haruo Hayashi of the Disaster Prevention Research Institute at Kyoto University. Attendees reaffirmed the importance of day-to-day disaster prevention activities, including the need to prepare for enormous disasters.

On-Site Disaster Prevention Inspections

![]()

Disaster prevention inspection

at Ceratechno Co., Ltd.

(Akashi Plant)

We conduct onsite disaster prevention inspections at our facilities in order to verify levels of compliance with disaster prevention legislation and minimize risks that could potentially lead to accidents.

Following on from the previous year, in fiscal 2012 we again conducted inspections at group companies. We found no serious legal violations, but had to correct deficiencies in equipment management.

Going forward, we will continue to reinforce disaster prevention management systems throughout the Kobe Steel Group.

Disaster Prevention Measures at Plants, Works and Offices

![]()

Despite making every effort to prevent accidents, we were once again unable to completely eliminate fires and other accidents during fiscal 2012. We have investigated the causes of all accidents and are taking appropriate action.

In the future, we will step up efforts to prevent recurring accidents, share information on accidents that have occurred, and cross-deploy disaster prevention activities aimed at preventing similar accidents, in an effort to eliminate accidents throughout the Kobe Steel Group.

Accidents and Incidents at Locations in Fiscal 2012

| Location | Number of Incidents | Location | Number of Incidents |

|---|---|---|---|

| Kobe Works | 0 | Moka Plant | 0 |

| Kakogawa Works | 5 | Chofu Works | 0 |

| Fujisawa Plant* | 0 | Daian Plant | 1 |

| Ibaraki Plant | 0 | Hariama Plant | 0 |

| Saijo Plant | 0 | Kobe Corporate Research Laboratories | 0 |

| Fukuchiyama Plant | 0 | Takasago Works | 0 |

* Includes the Production Center, Technical Center, and group company facilities.

Main Incidents in Fiscal 2012

| Date and Location | Incident |

|---|---|

|

October 2012 Kakogawa Works |

Hot molten steel leaked out from the cassette below a ladle in a continuous caster, burning out cables in the transport trolley. |

|

December 2012 Daian Plant |

Oil leaked out from a large press during forging, sparking a fire when it touched a hot die. The fire spread and burned out the upper part of the press. |

Disaster Prevention Activities at Plants, Works and Offices

![]()

Petrochemical Complex

Comprehensive Disaster

Drill (Kakogawa Works)

Practice hosing down an LPG

tank

Practice setting up an onsite

command headquarters

We conduct regular emergency drills at each of the Kobe Steel Group's plants, works and offices. In December 2012, we held a Petrochemical Complex Comprehensive Disaster-preparedness Drill at Kakogawa Works.

The purpose of the drill is to establish a system for rapidly coordinating and working with disaster prevention agencies and preventing the spread of damage in the event of a leak of oil, high pressure gas, or other flammable material and a resultant fire.

This drill was a comprehensive disaster drill conducted in cooperation with fire-fighting organizations and related agencies based on a scenario involving facilities damage cause by an earthquake, accumulation of wreckage from a tsunami, injured employees, a tank fire caused by aftershocks, and a ship fire caused by leaked heavy oil flowing onto the sea.

About 110 people from 11 disaster prevention agencies, including the fire department, Hyogo Prefectural Police Department, and the Japan Coast Guard, as well as approximately 200 people from local government offices and corporate personnel took part in the drill.

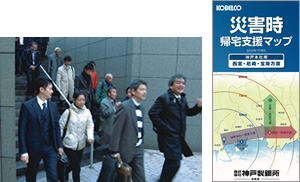

Drills for Returning Home in the Event of a Large-Scale Disaster

![]()

Left: Drill for returning home from the Tokyo

Head Office

Right: Kobe Head Office map for getting home

in a disaster

We held drills at the Kobe Head Office and Tokyo Head Office on how to return home in the event public transportation is not running due to an earthquake or other large-scale disaster. A total of 286 people took part.

Participants at the Kobe Head Office carried an original map for getting home in a disaster, checking points along the way that would be useful to know during a disaster, such as the locations of potential hazards, convenience stores, and toilets. They then contacted the office upon reaching their intended destinations, enabling us to confirm the safety of all participants.

We will continue these drills in the future along with the Kobelco 1/17 Walk that takes place in the area of the Kobe Head Office.

Promoting disaster prevention activities to become a corporate group trusted by communities and society

Koichiro Shibata, Officer & director

responsible for companywide

disaster prevention

Here at the Kobe Steel Group we are steadily continuing disaster prevention management activities, with the idea of complying with disaster prevention rules and regulations, enhancing management systems to eliminate accidents in the workplace, and being prepared in the event of a natural disaster.

In fiscal 2012, we undertook initiatives to reduce the risk of a disaster occurring by using examples other companies and past disasters as examples. We also put in place soft and hard measures with the highest priority on human life, to ensure that we are prepared in the event of a large-scale earthquake, tsunami, or other a natural disaster.

There is no end to disaster prevention and disaster reduction. That is why we are determined to steadily roll out disaster prevention activities step-by-step with the aim of being a corporate group that is trusted by communities and society and that is highly resistant to disaster.