Home > About Us > Sustainability Management > Sustainability Report > Sustainability Report 2014 > The Aluminum Value Chain

The Aluminum Value Chain

The Aluminum Value Chain

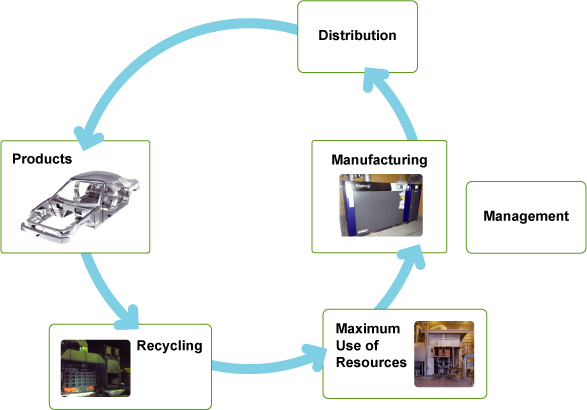

Creating added value by reducing the environmental impact in every process

From procurement of materials to product use, the Kobe Steel Group strives to reduce the environmental impact in every process. In particular, the Group has created a highly efficient value chain for aluminum products, with the majority of used products being recycled into new raw materials.

*We are also working to construct value chains that take advantage of the unique characteristics of raw materials in other businesses, such as in steel and machinery.

Manufacturing

![]()

The Kobe Steel Group pursues greater efficiency and energy savings for facilities and equipment used in every process.

The Kobe Steel Group utilizes a variety of original energy-saving technologies at its manufacturing locations, including regeneration burners that make use of waste heat produced during melting and state-of-the-art compressors that reduce loss.

Steam compressor

Melting furnace

Arc furnace

Management

![]()

All employees work to reduce energy usage at plants, offices and other locations.

A wide range of measures are in place to reduce energy usage, including proactive adoption of LED and metal halide lamps, use of natural lighting, extinguishing lights during lunch breaks, and reduction of energy consumed for air-conditioning through use of heat pumps and green walls.

Distribution

![]()

The Group strives for energy-efficient product shipping.

We take meticulous care to reduce the energy consumed during shipping, for instance by redesigning shipping routes in response to the locational conditions of our customers.

Products

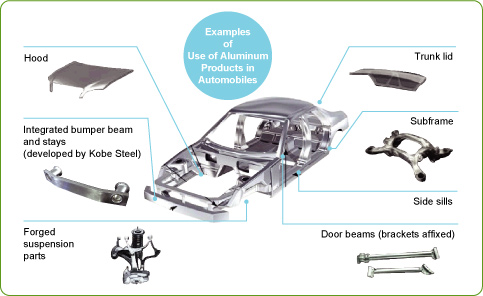

![]()

Aluminum products help reduce environmental impact in a variety of ways, such as lighter-weight automobiles and railway cars and lower CO2 emissions.

Utilizing materials and manufacturing technologies developed over many years, the Kobe Steel Group has developed a variety of aluminum vehicle parts that contributes to automotive lightweighting.

Recycling

![]()

Scrap recycling furnace

Aluminum is a highly recyclable material. The majority of aluminum products are recycled as a raw material.

The Moka Plant carries out "can-to-can" recycling, with a scrap recycling furnace on site for used beverage cans.

Maximum Use of Resources

![]()

Aluminum recycling furnace

Recovered aluminum

Aluminum is an important resource, which is why the Kobe Steel Group strives to make the most efficient use of it during manufacturing.

Some aluminum is lost during melting. However, the Moka Plant utilizes recovery equipment developed in house to reduce loss as far as possible and achieve more efficient manufacturing.