Home > About Us > Sustainability Management > Sustainability Report > Sustainability Report 2014 > Disaster Prevention Initiatives

Disaster Prevention Initiatives

Disaster Prevention Initiatives

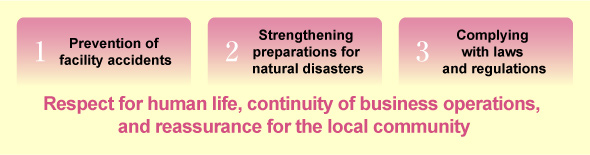

The Kobe Steel Group makes groupwide efforts to comply with laws and regulations, implement measures to guard against equipment accidents, and prepare for natural disasters through such means as establishing disaster management systems and holding regular training exercises. These measures are actively pursued to prevent accidents from occurring and to minimize damage if a disaster does strike.

We will continue to raise each and every employee's awareness of disaster prevention while continuing to carry out disaster prevention activities on a groupwide basis.

Fiscal 2013 Companywide Disaster Prevention Management Policy

![]()

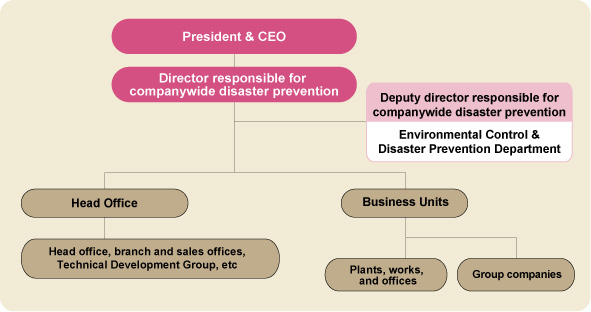

Companywide Disaster Prevention Management Structure

![]()

At the Kobe Steel Group, the head office, business units, business locations, and Group companies all implement disaster prevention management activities under the supervision of the president and the director responsible for companywide disaster prevention.

Companywide Disaster Prevention Management Structure

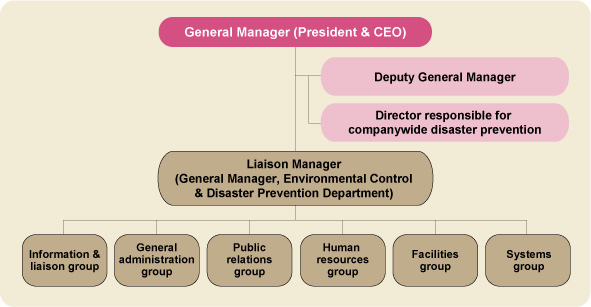

Disaster Management Structure

![]()

In the event of a large-scale earthquake or other natural disaster or accident we will set up a disaster management headquarters at our Tokyo Head Office or Kobe Head Office to coordinate relief efforts and restoration activities.

When the Great East Japan Earthquake struck in March 2011, we established a headquarters at our Tokyo Head Office to verify people's safety and provide assistance for affected locations. We also provided support to get operations up and running again as quickly as possible, including arranging and shipping relief supplies.

We intend to continue our educational and training activities in the future to ensure that we can respond to any disaster as smoothly as possible.

Disaster Management Headquarters Organization

Kobe Steel Group Disaster Prevention Meeting

![]()

We organize Kobe Steel Group Disaster Prevention Meetings every year in an effort to share information and strengthen disaster prevention initiatives. A total of 116 employees from 50 Group companies took part in our fiscal 2013 meeting, which featured updates on the latest revisions to laws and regulations, reports on initiatives at individual locations, and an explanation of the new Medium-Term Disaster Prevention Plan (Fiscal 2013-2015).

The meeting helped remind attendees of the importance of day-to-day disaster prevention activities.

On-site Disaster Prevention Inspections

![]()

on the premises of Kobelco

Eco-Solutions Co., Ltd.'s

Technical Research Center

We conduct on-site disaster prevention inspections at our facilities in order to verify levels of compliance with disaster prevention legislation and minimize risks that could potentially lead to accidents.

Following on from the previous year, in fiscal 2013 we again conducted inspections at group companies. We found no serious legal violations, but had to correct deficiencies in equipment management.

Going forward, we will continue to reinforce disaster prevention management systems throughout the Kobe Steel Group.

Disaster Prevention Measures at Plants, Works and Offices

![]()

Despite making every effort to prevent facility accidents, we were once again unable to completely eliminate fires and other accidents during fiscal 2013. We have investigated the causes of all accidents and are taking appropriate action.

In the future, in an effort to eliminate facility accidents throughout the Kobe Steel Group, we will step up efforts to prevent recurring accidents, share information on accidents that have occurred, and cross-deploy disaster prevention activities aimed at preventing similar accidents,.

Accidents and Incidents at Locations in Fiscal 2013

| Location | Number of Incidents | Location | Number of Incidents |

|---|---|---|---|

| Kobe Works | 0 | Moka Plant | 0 |

| Kakogawa Works | 2 | Chofu Works | 0 |

| Fujisawa Plant* | 0 | Daian Plant | 0 |

| Ibaraki Plant | 1 | Harima Plant | 0 |

| Saijo Plant | 0 | Kobe Corporate Research Laboratories | 0 |

| Fukuchiyama Plant | 0 | Takasago Works | 0 |

*Includes the Production Center, Technical Center, and group company facilities

Facility Accidents in Fiscal 2013

| Date and Location | Incident |

|---|---|

|

July 2013 Kakogawa Works |

A conveyor belt caught fire due to high-temperature sintered ore. |

|

November 2013 Ibaraki Plant |

While installing a signboard, a wire from the board came in contact with a crane trolley, sending out sparks which ignited dust accumulated in the dust collector. |

|

March 2014 Kakogawa Works |

While removing an ingot from a bag at the steelmaking plant, the ingot broke and the unsolidified portion inside the ingot ran out. The explosion of steam caused the ingotto fly apart and some of the materials nearby caught fire. |

Disaster Prevention Activities at Locations

![]()

Firefighting Competition held

by the Ogaki Fire Department

We conduct regular emergency drills at each of the Kobe Steel Group's plants, works, offices and other locations.

In April 2014, the Kobe Corporate Research Laboratories carried out a comprehensive large-scale earthquake drill. The drill was run by 11 municipal firefighters, and all 873 employees at the laboratories, including those from affiliated companies and subcontractors, participated. The drills focused on initial response and included evacuation from the building; use of fire hydrants, engine pumps and on-site ambulances; and carrying out roll calls and delivering messages without relying on landlines or mobile phones.

Members from the Kobelco Construction Machinery Co., Ltd. Hiroshima and Ogaki factories also participated in local firefighters' events to raise their awareness of fire prevention. In Fiscal 2013 members from the Ogaki Factory participated in indoor fire hydrant and extinguisher events in the Private Business First Response Firefighting Competition held by the Ogaki Fire Department. In order to raise fire prevention awareness among all employees the factory primarily sent employees who had yet to compete in the tournaments. We will continue to send employees to these mees in order to raise disaster prevention awareness.

The KOBELCO 1/17 Walk

![]()

home in a disaster

The 8th Kobelco 1/17 Walk was held on January 25, 2014 near the Kobe Head Office with 143 participants. The event is held to confirm roads to and from work in the event that an earthquake disrupts public transportation services.

Having learned from our experiences during the Great Hanshin Awaji Earthquake of 1995, the Kobe Head Office created a folding map designed from the perspective of pedestrians. The map is used during the 1/17 Walk to identify areas prone to tsunami flooding as well as spots that could be useful during emergency, such as convenience stores and toilets.

We will continue to carry out this walk at the Kobe and Tokyo head offices, in conjunction with drills in place to practice returning home during a disaster.

We engage in disaster prevention activities, with the aim of becoming a corporate group that is trusted by the community.

Makoto Mizuguchi,

director responsible for

companywide disaster prevention

(Senior Officer)

Disaster prevention activities for the Kobe Steel Group are carried out according to three basic principles: prevention of facility accidents, strengthening preparations for natural disaster, and compliance with disaster-related laws and regulations.

In fiscal 2013, guided by examples from the past and from other companies, we steadily implemented accident prevention measures and strove to raise disaster prevention skills. We also increased preparations for a variety of natural disasters, both foreseeable and unforeseeable, such as large-scale earthquakes, tsunamis and local flooding. Both hard and soft measures were implemented and drills corresponding to a variety of situations were carried out.

We will continue to implement activities, step-by-step, with the aim of being a corporate group that is trusted by the community and that is highly resilient to disasters.