Home > About Us > Sustainability Management > Sustainability Report > Sustainability Report 2015 > Unparalleled Products and Services

Unparalleled Products and Services

Unparalleled Products and Services

Providing "reliable technologies, products, and services" is one of the aims set out in the Kobe Steel Group's Corporate Philosophy. By strengthening our monozukuri-ryoku, or manufacturing capabilities, we aim to maintain the trust of our customers and business partners, both in and outside Japan, by continuing to supply unparalleled products and services.

MONODZUKURI (Production System Innovation) Planning and Promotion Department

![]()

The MONODZUKURI (Production System Innovation) Planning and Promotion Department has been working to improve information sharing, synergy, and human resource development.

The department is currently working to strengthen quality, procurement and energy conservation so as to increase manufacturing capabilities throughout the Kobe Steel Group and enable the Group to continue offering trustworthy products and services.

Strengthening Groupwide Collaboration

![]()

Representatives from each plant participate in our Leaders' Meetings for Monozukuri Promotion. These meetings allow participants to discuss companywide policies, present examples of positive initiatives and share information. Our Production Technology Exchange Meetings, meanwhile, provide an opportunity for engineers to share information on elemental technologies and raise the Group's overall technical level.

Leaders' Meetings for Monozukuri Promotion

![]()

Each plant in the Group has a monozukuri promotion leader (at the general manager or deputy general manager level) who acts as a contact person for Kobe Steel Group monozukuri promotion activities. The leaders gather for regularly held Leaders' Meetings for Monozukuri Promotion. Examples of in-house and outside initiatives are reported on, progress reports for ongoing initiatives are shared, and debates on new measures are carried out.

Initiatives outlined during these meetings are then used as guidelines for improvement activities at each plant. When members are interested, we also arrange for on-site meetings to directly inspect the improvements introduced.

Sharing examples of outstanding advancements

A leaders' meeting to discuss current challenges

Production Technology Exchange Meetings

![]()

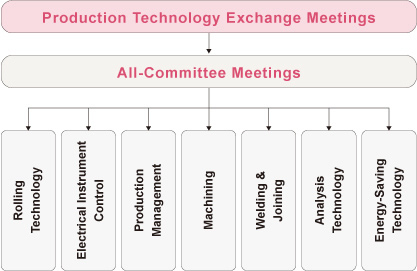

The Kobe Steel Group holds Production Technology Exchange Meetings to allow engineers from different locations in shared technological fields to interact and exchange ideas.

The meetings currently include seven subcommittees split according to technological field, as shown in the diagram below.

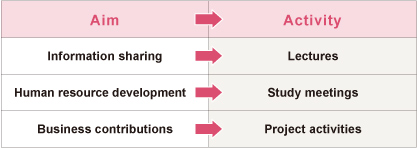

These subcommittees go beyond the organizational framework of business units and companies. Engineers participate and tackle the issues of information-sharing, human resource development and business contributions.

Information-sharing is carried out through lectures. Lectures are carried out once or twice per year per subcommittee, with the location rotating between related company sites. At these lectures, information on outstanding cases is shared by the persons directly involved.

Regarding human resource development, subcommittees identify the elemental technologies required in their field and then hold study workshops to improve their knowledge of these technologies.

Regarding business contributions, project teams are formed in each subcommittee to address challenges shared throughout that technological field.

For instance, the Machining Subcommittee offered guidance to manufacturing locations on machining improvements using the "Optimum Machining Conditions System" jointly developed by the Machinery Business and the Technical Development Group. By bringing new insight to improvements being pursued independently at individual locations, we will continue to create ever more effective improvement proposals.

Production Technology Exchange Meetings

Production Technology Exchange Meeting Initiatives

Improving welding capabilities

Machining Subcommittee lecture

Initiatives to Strengthen Quality

![]()

Each Kobe Steel Group location adopts quality management systems (such as ISO 9001 certification) and strives to improve quality through customer satisfaction surveys.

For instance, the Quality Assurance Department at Kobelco Construction Machinery carries out customer satisfaction surveys to gauge customers' perceptions and strives to meet customers' increasingly sophisticated demands for quality.

Order of priority for improvement activities

| 1. Safety | Putting safety first |

|---|---|

| 2. Quality | Ensuring safety, improving quality |

| 3. Delivery | Ensuring safety and quality, improving productivity |

| 4. Cost | Ensuring safety, quality, and productivity, cost reductions |