In order to make effective use of limited resources, the Kobe Steel Group implements measures to control waste at its offices and plants. We add value to byproducts created during manufacturing processes, develop new applications for materials and actively pursue recycling. We reduce waste during shipping by simplifying packaging methods and introducing lighter weight packaging throughout the Group. We are also working to reduce paper consumption at offices by proactively digitizing meeting materials and introducing IT throughout the Group.

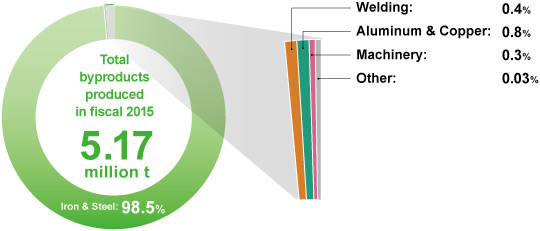

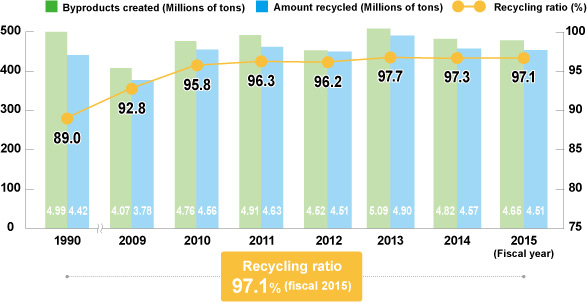

In fiscal 2015, a total of 5.17 million tons of byproduct materials were created by the Kobe Steel Group, including overseas Group companies, with approximately 98.5 percent coming from the Iron & Steel Business. At the steelworks, we strive to recycle and add value to secondary materials produced during iron and steelmaking such as slag* and dust. In fiscal 2015, the recycling ratio for all of Kobe Steel was 97.1 percent, while the overall ratio for the Kobe Steel Group, including overseas Group companies, was 97.5 percent.

In addition to recycling, we also follow a fundamental policy of reducing the volume of waste generated by thoroughly adjusting the amount of raw materials and auxiliary materials used (improving productivity). As a result, in fiscal 2015 we were able to achieve the targets laid out in our voluntary action plans (i.e. target numbers for waste consigned to landfill and recycling).

Throughout the Kobe Steel Group, including overseas companies, Kobe Steel consigned 130,000 tons of waste to landfills. We plan to continue to reduce this amount and achieve our targets through measures such as controlling the amount of waste generated, increasing recycling, developing new recycling technologies and adding value to byproducts.

* Iron and steel slag is a byproduct separated and recovered during iron and steel refining.

Byproducts by Business Unit (Includes Japanese and Overseas Group Companies)

Byproducts, Amount Recycled and Recycling Ratio (Kobe Steel)

* Recycling ratio = Amount recycled/total amount of byproducts

In each business unit and at each location, we implement action programs to reduce levels of waste consigned to landfills and aim for even greater levels of added value through reducing and reusing waste, developing recycling technologies, and creating new avenues for use.

Kobe Steel continues to develop new technologies for the recycling of steel slag and dust as well as new uses for recycled material. As a result, in fiscal 2015 Kakogawa Works, Kobe Works and Takasago Works limited waste consigned to landfills to approximately 90,000 tons.

Through the stable operation of a new hot-metal treatment plant, Kakogawa Works has reduced the amount of slag* produced per unit.

In fiscal 2015, 2.38 million tons of blast furnace slag* and 1.03 million tons of steel slag* were produced at Kakogawa Works and Kobe Works. The works pursue appropriate operation and management, in line with the “Guidelines for Management of Iron and Steel Slag Products” established by the Nippon Slag Association.

As part of research into development of new uses for recycled slag, demonstration tests were held at Iwaya Port (Awaji Island, Hyogo Prefecture). The tests established that slag can possess exceptional environmental value and can be used to promote the growth of seaweed beds. As a result, Kobe City will now begin using slag as a harbor material in its public works.

* Blast furnace slag, steelmaking slag: Products classified as blast furnace slag and steelmaking slag are generated in the ironmaking process in the blast furnace and in the steelmaking process in the steelmaking plant, respectively.

The Welding Business established resource recycling action plans and pursues a variety of measures at each of its locations. The know-how behind such measures is shared throughout the Business via regular meetings.

At the Ibaraki Plant we are working to reduce waste oil through improvements to oil coating equipment. We strive to thoroughly reduce waste flux at the Fujisawa and Saijo plants and pursue recycling of waste flux at the Fujisawa Plant.

At Kobelco Welding of Europe B.V. (Netherlands) and Kobe Welding of Korea Co., Ltd. (South Korea), we are working to reduce waste through the reuse of lubricants.

Drawing on the cutting-edge initiatives for controlling waste that are in place at individual locations, the Aluminum & Copper Business pursues horizontal development at its locations that aim to improve the resource recycling rate of the business unit as a whole.

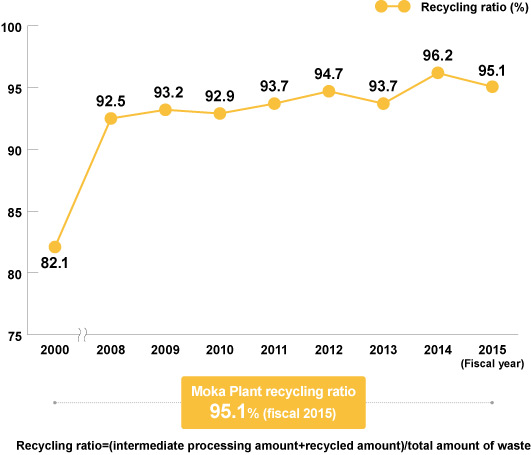

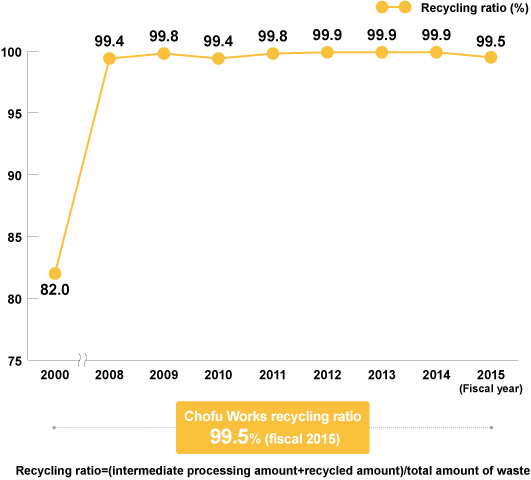

We continue to roll out activities at our three manufacturing locations within Japan to reduce waste consigned to landfills and increase recycling ratios. We have achieved high recycling ratios at all three sites as a result. At the Chofu Works, in particular, as a result of aggressive measures, we have achieved a recycling ratio of 99.5 percent.

At Shinko Leadmikk Co., Ltd. we are striving to reduce waste alkali through improvements to production processes and other measures.

Moka Plant Recycling Ratio

Chofu Works Recycling Ratio

In the Machinery Business, a high resource recycling ratio is maintained through previously implemented measures that have taken root.

The Takasago machinery plants, which manufacture nonstandard compressors and industrial machinery, have been aggressively introducing measures to reduce waste (from the source) and increase recycling. Additionally, the Harima Plant, which makes standard compressors, maintains zero waste consigned to landfills, through recycling measures such as the introduction of returnable containers for parts packing.

Topics

Initiatives Related to Packing Materials (Introduction of Simple Packaging Combining Effectiveness with Environmental Friendliness, Recycling of Packing Materials)

At Kobelco Advanced Lube-System Asia Co., Ltd. (South Korea), which handles the manufacture, sales, after-service and maintenance for a variety of lubricating oil units, we are aggressively transitioning to simpler packaging. Additionally, at Kobelco Spring Wire (Foshan) Co., Ltd. (China), which produces and sells high-grade spring steel wires, we are striving to improve the reuse of unnecessary packing materials and packaging for our clients.

In order to reduce waste, we are also promoting the reuse of wooden pallets, packaging papers and film at other locations.