The Kobe Steel Group makes groupwide efforts to comply with laws and regulations, implement measures to guard against equipment accidents, and prepare for natural disasters through such means as establishing disaster management systems and holding regular training exercises. These measures are actively pursued to prevent accidents from occurring and to minimize damage if a disaster does strike.

We will continue to raise each and every employee's awareness for disaster preparedness while continuing to carry out disaster prevention activities on a groupwide basis.

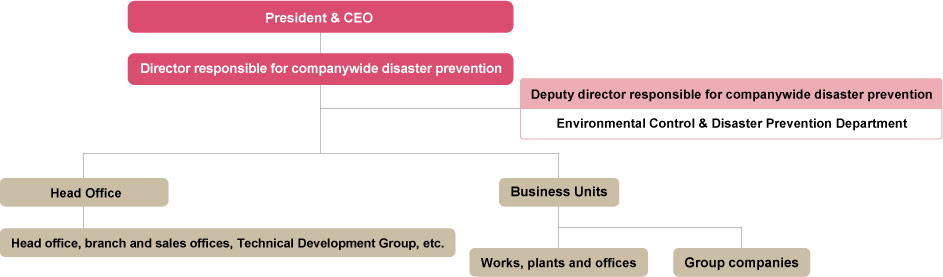

At the Kobe Steel Group, the head office, business units, business locations, and Group companies all implement disaster prevention management activities under the supervision of the president and the director responsible for companywide disaster prevention.

Companywide Disaster Prevention Management Structure

We organize the Kobe Steel Group Disaster Prevention Meeting every year in an effort to share information and strengthen disaster prevention initiatives. A total of 104 employees from 38 Group companies took part in our fiscal 2015 meeting. In addition to natural disaster countermeasures such as notification and contact protocols, satellite telephones, earthquake early warnings and tsunami and landslide preparedness, we also reported on examples of accidents

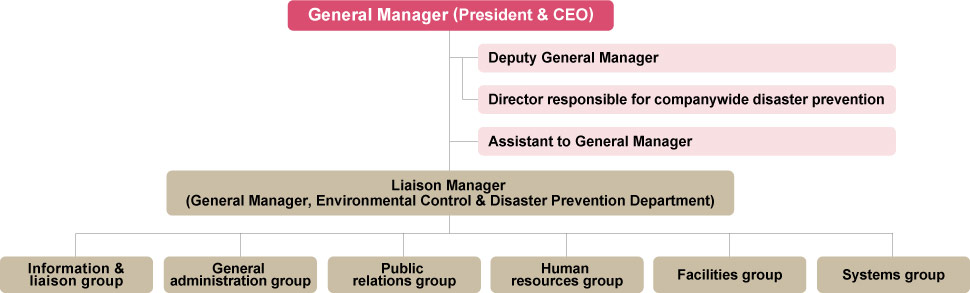

In the event of a large-scale earthquake or other natural disaster or accident, we will set up a disaster response headquarters at our Tokyo Head Office or Kobe Head Office to coordinate relief efforts and restoration activities.

On March 10, 2016, we established a disaster management headquarters and began implementing drills in preparation for the possibility of a major earthquake in the Nankai Trough. The drills focused on first response immediately after an earthquake occurs and support measures after 24 hours have passed. We will continue training in the future to ensure even smoother responses.

Disaster Response Headquarters Organization

Although the Kobe Steel Group makes every effort to prevent fires and other accidents before they occur, in fiscal 2015 there were five facility-related accidents at Kobe Steel locations and seven at Group companies. We have investigated the causes of all accidents and are taking appropriate action.

In the future, we will carry out extensive efforts to eliminate facility accidents throughout the Kobe Steel Group, including sharing information on accidents occurring within and outside the company and coordinating with voluntary action plans from industrial associations.

Facility Accidents at Kobe Steel Locations in Fiscal 2015

| Date and Location | Incident |

|---|---|

| April 2015

Kakogawa Works |

Fuel gas leaked from a crack in the fuel gas booster fan case at the hot strip mill's heating furnace, causing a fire. |

| June 2015

Kakogawa Works |

A malfunction occurred at the burner air pipe of the annealing furnace at the cold rolling mill, resulting in uncombusted gas igniting and causing a fire. |

| June 2015

Kakogawa Works |

Oil leaked from the hydraulic hose at the kiln in the lime plant and caught on fire. |

| November 2015

Daian Plant |

Molten magnesium leaked from the top part of the caster mold, burning hoses and other equipment. |

| February 2016

Kobe Works |

Slag was sent flying by a steam explosion at the steelmaking slag treatment area, burning nearby heavy machinery. |

We conduct regular emergency drills at each of the Kobe Steel Group's business locations including works, plants and offices.

We implemented comprehensive plant-wide drills (daytime/nighttime) for major earthquakes or fire at the Ibaraki Plant, practicing responses during early earthquake warnings and evacuation methods.

Additionally, we installed satellite phones, as a means of providing emergency communication channels, at all Kobe Steel company locations.

In order to protect the lives of our employees, and minimize any damage to the surrounding area, we will continue to strengthen emergency countermeasures.

In the event of an earthquake or other large-scale disaster, public transportation will likely become unavailable. We held drills at five locations throughout the Company, for employees to practice returning home during such an event.

At the Osaka Branch Office 19 employees participated, travelling to a distance approximately 6 km, while checking for potentially dangerous areas, as well as useful spots (such as convenience stores) as they travelled. The drill served as a reminder of the importance of practicing return routes in advance.

Kobe Steel's corporate headquarters conducts on-site disaster prevention inspections of facilities in order to verify levels of compliance with disaster prevention laws and regulations, and to minimize risks that could potentially lead to accidents.

No significant violations were found during inspections at Kobe Steel locations and Group companies in fiscal 2015.

Going forward, we will continue to reinforce disaster prevention management systems throughout the Kobe Steel Group.

We engage in disaster preparedness activities, with the aim of becoming a corporate group that is trusted by the community.

I offer my heartfelt condolences for all those who were affected by the earthquake in Kumamoto.

At the Kobe Steel Group, disaster prevention activities are carried out according to three basic principles: prevention of facility accidents, strengthening preparations for natural disaster, and compliance with disaster-related laws and regulations.

For disaster prevention, we used case studies from within and outside the company as references and implemented activities to reduce risks related to accidents.

Regarding disaster preparedness, we implemented both prevention and mitigation initiatives, working to grasp risks related to earthquakes, tsunami, landslides and other disaster, strengthen countermeasures, and promote education and training.

In the future as well, we will steadily implement each and every activity with diligence and faith, striving to live up to our ideals as a corporate Group that is strong against disaster and deserving of the trust of our local communities and clients.