We aim to be the world's most trusted company for welding solutions, offering total solutions, including welding materials, robotic welding systems and construction technologies.

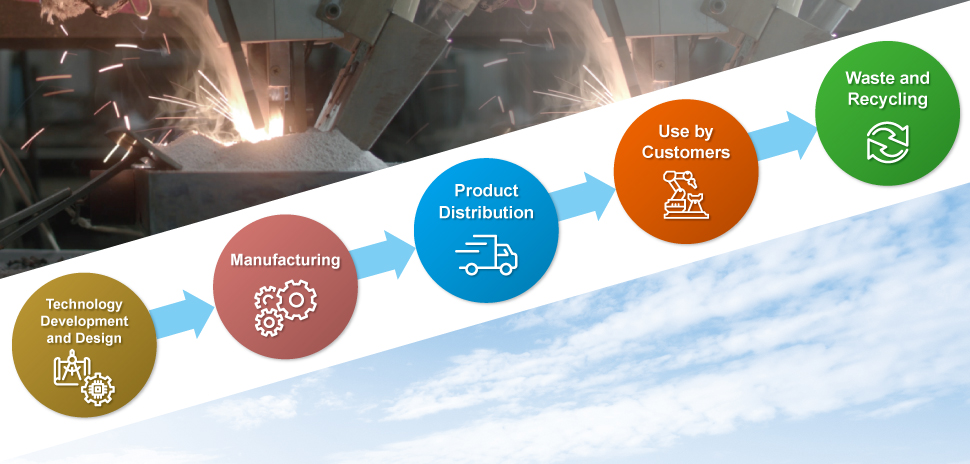

In all of our many technologies and products, from development and design to waste and recycling, the Welding Business conserves energy, decreases CO2 emissions, and otherwise contributes to reduced environmental impact.

Example of Initiatives

Reducing CO2 through weight savings in transportation (such as for automobiles and marine vessels) requires technologies necessary for welding strong, lightweight steel sheet. We have developed a diverse array of welding materials and construction technologies to meet society's needs.

Example of Initiatives

Topics

Energy-Saving Patrols

Aiming to rationalize energy use, all employees engage in plant-wide activities to improve facilities, rectify air leaks and otherwise save energy.

Example of Initiatives

We are introducing extensive modal shifts in transportation, shifting from trucks to transportation such as rail and ships. We reduce the energy required for transportation through direct shipping to customers without the use of intermediate warehouses.

Welding Materials

Kobe Steel manufactures and sells approximately 800 different types of welding materials. These materials help contribute to better manufacturing in a wide variety of industries, including the shipbuilding, steel frame and automotive sectors.

Example of Initiatives

We have commercialized and launched the TRUSTARC™ MG-S120T for the welding of ultra high-strength steel sheet, which is expected to reduce the weight of cars and reduce CO2 emissions.

Welding Systems

Kobe Steel boasts top results in Japan in fields such as structural construction steel and construction machinery. We offer optimal welding solutions that not only automate welding work and improve efficiency, but also help reduce costs and improve quality for customers.

Example of Initiatives

We contribute to improved working environments, through use of the REGARC™ welding process, which greatly decreases fumes and spatter in comparison to previous methods, in conjunction with welding wires specifically tailored to REGARC™ technology.

Example of Initiatives

In addition to efforts to reduce waste flux, we are also reducing landfills through the recycling of neutralized sludge into cement materials.