Providing "reliable technologies, products, and services" is one of the aims set out in the Core Values of KOBELCO. By strengthening our monozukuri-ryoku, or manufacturing capabilities, we aim to maintain the trust and satisfaction of our customers and business partners, both in and outside Japan, through unparalleled products and services.

The MONODZUKURI (Production System Innovation) Planning & Promotion Department has been working to improve information sharing, synergy, and human resource development, in order to strengthen the monozukuri-ryoku, or manufacturing capabilities, of the Kobe Steel Group.

We will continue to work to strengthen quality, on-site manufacturing capabilities and energy conservation so as to increase manufacturing capabilities throughout the Kobe Steel Group and provide reliable products and services.

Representatives from each manufacturing facility participate in our Leaders' Meetings for Monozukuri Promotion. These meetings allow participants to discuss companywide policies, present examples of positive initiatives and share information. Our Production Technology Exchange Meetings, meanwhile, provide an opportunity for engineers to share information on elemental technologies and raise the Group's overall technical level.

Each manufacturing facility in the Group has a monozukuri promotion leader (at the general manager or deputy general manager level) who acts as a contact person for Kobe Steel Group monozukuri promotion activities. The leaders gather for regularly held Leaders' Meetings for Monozukuri Promotion. Examples of in-house and outside initiatives are reported on, progress reports for ongoing initiatives are shared, and debates on new measures are carried out.

Initiatives outlined during these meetings are then used as guidelines for improvement activities at each facility. When members are interested, we also arrange for on-site meetings with the facilities where improvements have been introduced.

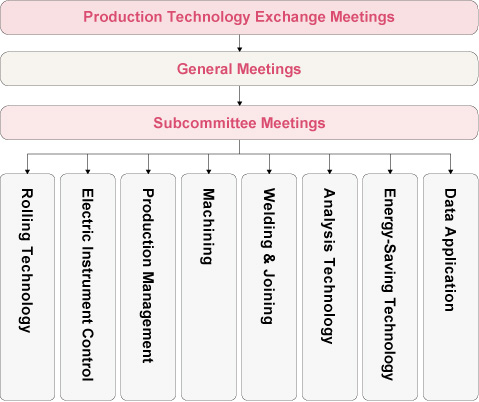

The Kobe Steel Group holds Production Technology Exchange Meetings to allow engineers to interact and exchange ideas with others in the same fields in the Group. The meetings currently include eight subcommittee meetings split according to technological field, as shown in the diagram below.

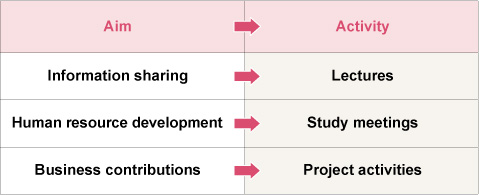

These subcommittee meetings go beyond the organizational framework of business units and companies. Engineers participate and tackle the issues of information-sharing, human resource development and business contributions.

Production Technology Exchange Meetings

Production Technology Exchange Meeting Initiatives

Each Kobe Steel Group location has adopted quality management systems (such as ISO 9001 certification) and strives to improve quality through customer satisfaction surveys.

The valuable opinions and requests received through customer satisfaction surveys are shared with executive personnel and relevant persons. We strive to strengthen our monozukuri-ryoku, so as to provide products and services that win customers' trust and satisfaction.

Order of Priority for Improvement Activities

| 1. Safety | Putting safety first |

|---|---|

| 2. Quality | Ensuring safety, improving quality |

| 3. Delivery | Ensuring safety and quality, improving productivity |

| 4. Cost | Ensuring safety, quality and productivity, reducing costs |

5S inspection

As the basis for on-site manufacturing capabilities, the Kobe Steel Group considers 5S* activities to be of utmost importance, and is working to strengthen such activities for all manufacturing workplaces.

We also proactively promote on-site Quality Control Circle Activities. In particular, we hold a KOBELCO Quality Control Circle Conference once per year, aiming to improve the level of activities through Group-wide, cross-functional information sharing and education.

* 5S stands for seiri (sort, classify), seiton (set in order, straighten up), seiso (shine, clean), seiketsu (standardize practices), and shitsuke (sustain discipline). 5S activities stress the importance of improving the work environment on the manufacturing floor.