Home > Notices > Notices > Binary cycle power generation system for ships passes tests, Receives approval from ClassNK, Installation on actual ship in May 2016

Notices

The information on this Web site is presented "as is." Product availability, organization, and other content may differ from the time the information was originally posted. Changes may take place without notice.

![]()

Binary cycle power generation system for ships passes tests,

Binary cycle power generation system for ships passes tests,

Receives approval from ClassNK,

Installation on actual ship in May 2016

December 2, 2015

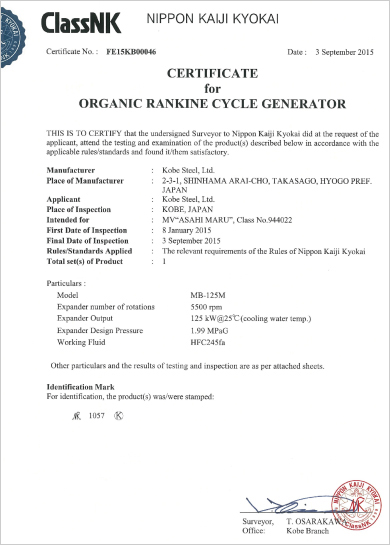

Kobe Steel, Ltd., ASAHI SHIPPING CO., LTD. and MIURA CO., LTD. began joint development of a binary cycle power generation system for ships in April 2014. Land-based testing of the binary cycle power generation system has recently been completed, and the system has received approval from Japan’s ship classification society Nippon Kaiji Kyokai (also known as ClassNK), a general incorporated foundation (“ippan zaidan hojin”).

ASAHI SHIPPING, an industrial carrier for Kobe Steel, has commissioned TSUNEISHI SHIPBUILDING Co., Ltd. to undertake mounting work of the binary cycle power generation system on the MV ASAHI MARU, a large coal carrier owned by ASAHI SHIPPING that serves Kobe Steel, in May 2016. The system will undergo performance assessments on the ship. After completing development in fiscal 2016, ending March 2017, Kobe Steel aims to commercialize the binary cycle power generation system.

In order for the binary cycle power generation system to be introduced as “environmental equipment” evaluated by ClassNK under its Environmental Guideline, ASAHI SHIPPING and the other companies are contributing to revision work of the Environmental Guideline—using the knowledge cultivated in the development of this system—to create a new classification, “waste heat power generation,” which is being promoted by ClassNK.

The binary cycle power generation system uses the heat emitted from the ship’s engine, which has largely gone unutilized in the past, as the heat source to generate approximately 100 kW (sending end output). The electricity will serve as auxiliary power and contribute to the efficient utilization of energy and reduction of CO2 emissions. As originally anticipated, land-based testing confirmed that it would be possible to reduce fuel consumption and CO2 emissions by 2.6 to 2.9 percent per year.

In this project, Kobe Steel developed the new binary cycle power generation system for ships, while MIURA developed an evaporator to recover the heat source. The binary cycle power generation system will be constructed on the MV ASAHI MARU, a large coal carrier owned by ASAHI SHIPPING that serves Kobe Steel. TSUNEISHI SHIPBUILDING will be responsible for overall engineering.

The power generation system is noted for two original features:

- As the binary cycle power generation system is applicable for main engines in the 5,000-kW class and higher, which are used by most vessels, the system can be used in a wide variety of ships.

- The main engines in ships undergo large load fluctuations. The binary cycle power generation system can generate electricity under a wide range of conditions, from high loads (about 70-90%) to low loads (about 50%).

This project has been adopted as a joint research theme by Japan’s Ministry of Land, Infrastructure, Transport and Tourism and ClassNK.

Background Information

![]()

* Note

![]()

With environmental problems in the shipping industry drawing increasing attention, ClassNK has been promoting the identification of ships that have introduced environmental technology using evaluation criteria compiled in its Environmental Guideline, as a way to evaluate technology that has achieved a reduction in the environmental load. As the binary cycle power generation system for ships and other so-called products for waste heat power generation are in a new field, ClassNK is pushing forward with revision work on the Environmental Guideline to create a new classification that recognizes the advantages in environmental terms of the new binary cycle power generation system.

Initiatives Undertaken by the Companies

![]()

Kobe Steel

![]()

Kobe Steel developed the binary cycle power generation system for ships. Since 2011, Kobe Steel has been selling a power generation system called Microbinary. This system produces electricity from a turbine driven by steam generated by vaporizing a working medium, using factory waste heat as the heat source. For marine main engines, which undergo large load fluctuations, the new binary cycle power generation system can generate electricity under a wide of conditions, from high loads to low loads.

ASAHI SHIPPING

![]()

ASAHI SHIPPING will mount the binary cycle power generation system on its ship. Gathering data on the effectiveness of the new power system, ASAHI SHIPPING will share data on various operating conditions with joint researchers so that improvements can be made to the binary cycle power generation system. The safety, economy, operability and other factors of the system will be confirmed. ASAHI SHIPPING will serve as the facilitator of this research and study, responsible for schedule coordination, results compilation and other aspects.

With the cooperation of shipbuilder TSUNEISHI SHIPBUILDING, which is commissioned to undertake the mounting work on the ship, ASAHI SHIPPING will provide ship data to the other companies. ASAHI SHIPPING will also determine the optimum place on the ship to install the binary cycle power generation system, by applying model analysis using 3D CAD and 3D scanners and considering the necessary pipework and possibility of manufacturing.

MIURA

![]()

MIURA developed the evaporator, in which the heat of compression from the supercharged air is transferred to the medium, for the binary cycle power generation system for ships. In the limited space on a ship, using an evaporator in which heat exchange can be effectively utilized contributes to reducing fuel consumption and CO2 emissions.

TSUNEISHI SHIPBUILDING

![]()

TSUNEISHI SHIPBUILDING is responsible for undertaking the mounting and installation work of the binary cycle power generation system on the MV ASAHI MARU, which is currently in service. Since 2013, the company has been making drawings of the engine room using a 3D scanner. It has also started on the layout design and detailed design. In 2015, whenever the ASAHI MARU has called at port at certain steelworks, piping and other installation work has been undertaken and completed as needed. Preparations for mounting major equipment on the ship, scheduled to be conducted at the end of this year and early next year, are underway.

Certificate from ClassNK

MV ASAHI MARU