June 29, 2021

Kobe Steel, Ltd.

Kobe Steel, Ltd. announces that it has decided to invest approximately 15 billion yen in the steel plate plant at Kakogawa Works to carry out a refurbishment of a finishing rolling mill. The refurbishment work is scheduled to take place in the second half of fiscal 2023 for a period of approximately 80 days.

Since the start of operation of the steel plate plant in 1968, Kobe Steel's steel plate business has been contributing to the development of communities and the manufacturing of social infrastructures while providing safety and security in these fields. Kobe Steel’s original steel plate products include Eco-View, a highly durable steel plate for bridges. In addition, our steel plate business has been offering unique solutions to customers in cooperation with the Company’s welding business and technical development group.

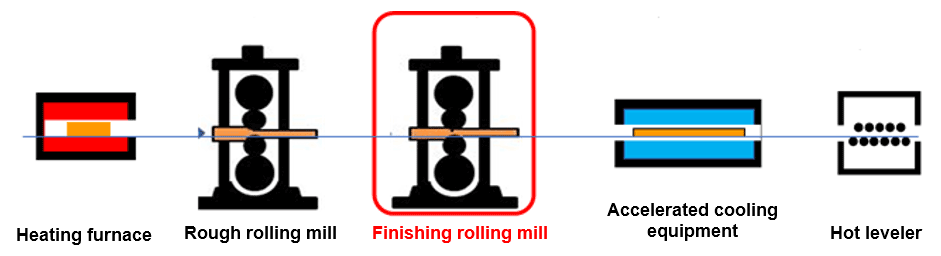

The finishing rolling mill is a machine for rolling slabs, heated in the heating furnace, to the thickness of a product after the process of increasing the width in the rough rolling mill. This capital investment will be used for upgrading the main body and the main motor of the finishing rolling mill as well as for enhancing functions such as improving the rigidity*1) of the mill. This will lead not only to strengthening the product supply system with stable quality and delivery time, but also promoting the development of high-functional steel plate manufacturing technology.

Through this refurbishment, Kobe Steel's steel plate products will achieve the highest performance and competitiveness in the industry. With such advantages, we will strive to further contribute to the enhancement of social capital while responding to various customer needs that are expected in the future, such as the replacement of ships and the reconstruction of buildings to reduce greenhouse gas emissions, the renewal of bridges to strengthen national infrastructure, etc. Moving forward with these efforts, we aim to realize a world in which people, now and in the future, can fulfill their hopes and dreams while enjoying safe, secure, and prosperous lives as envisioned in the KOBELCO Group’s Corporate Philosophy.

*1) Rigidity (of a rolling mill) refers to the ability to withstand deformation that occurs in the vertical, horizontal, and diagonal directions of a rolling mill during rolling of a material with four upper and lower rolls. The less deformation and the more robustness of the rolling mill, the less dimensional variations can be caused in steel plate products. With this refurbishment, the finishing rolling mill will have higher rigidity.

(Note) The information on this web site is presented "as is." Product availability, organization, and other content may differ from the time the information was originally posted. Changes may take place without notice.