February 27, 2025

Kobe Steel, Ltd.

Nippon Kaiji Kyokai (ClassNK) granted a Statement of Feasibility for Technology Qualification*1 on February 14th for Kobe Steel’s ultra-low temperature hydrogen reciprocating compressor developed for the maritime shipping industries.

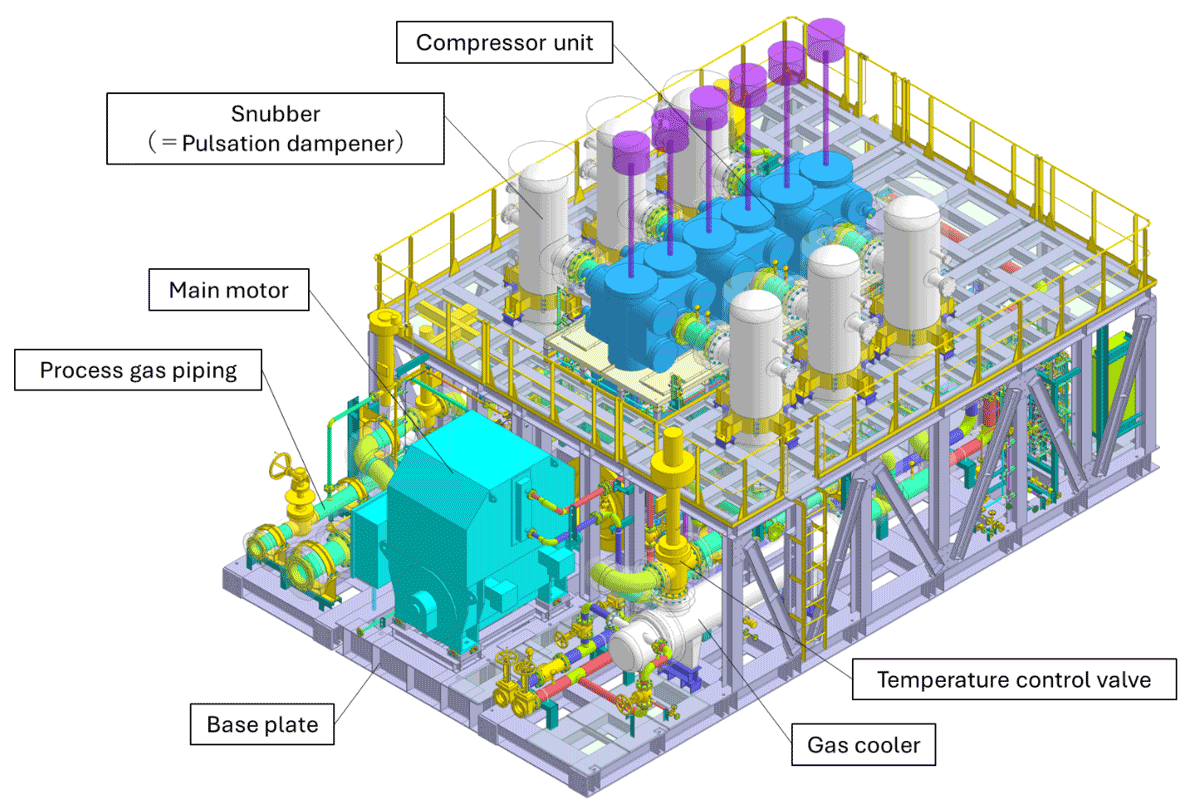

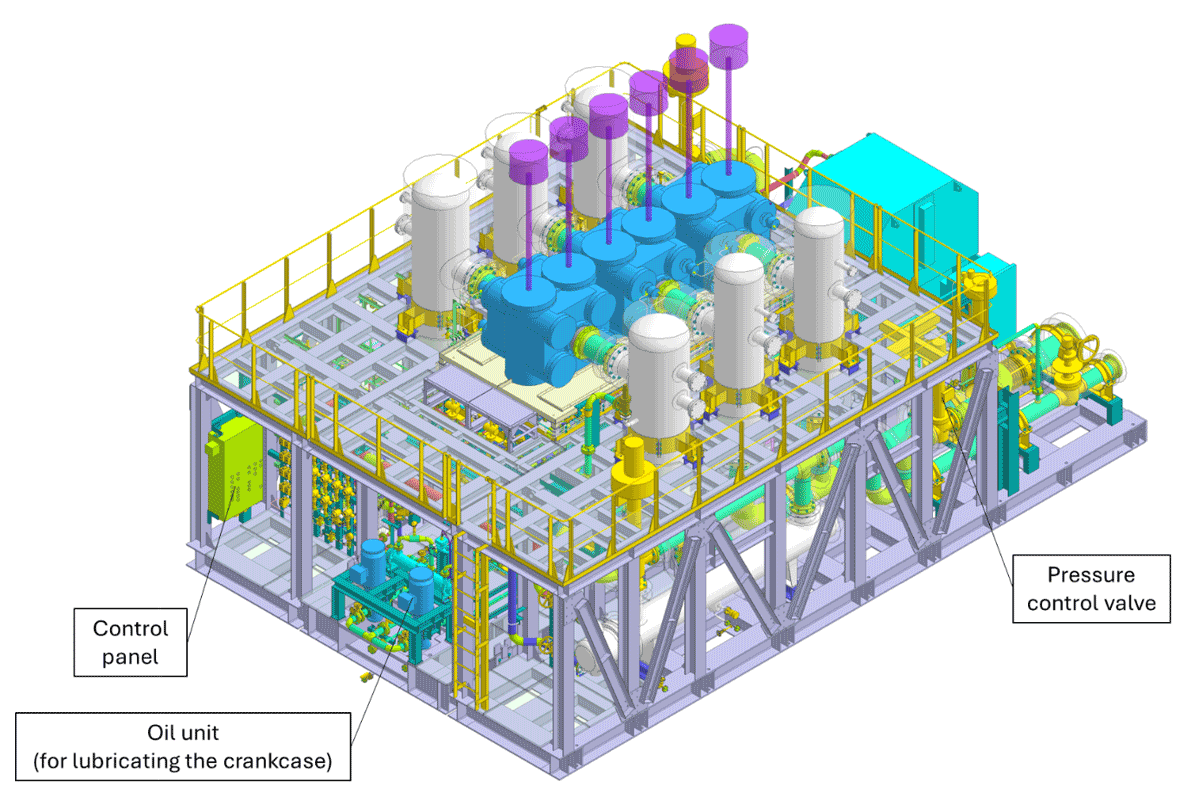

As part of its effort to realize a carbon-neutral society, Kobe Steel has been working on the design of a reciprocating compressor capable of taking in and compressing ultra-low temperature hydrogen with the aim of introducing a new application in the hydrogen compressor industry. This is the Company’s first ultra-low temperature hydrogen compressor while it has an extensive track record of delivering compressors for room temperature hydrogen and ultra-low temperature LNG boil-off gas. The demand for ultra-low temperature hydrogen reciprocating compressors is projected to grow primarily for the use in liquefied hydrogen transportation and storage facilities, however there are technical challenges to overcome, including hydrogen embrittlement and low-temperature embrittlement of the materials used, high thermal stress in equipment and piping, and hydrogen gas leakage.

As a result of addressing these technical issues, the Company has received the Statement confirming that the ultra-low temperature hydrogen reciprocating compressor has completed Step 2 (Analysis of technology elements), the second step of the four-step technology qualification process*2 outlined in ClassNK’s Technology Qualification Guidelines.

For this qualification, a special team made up of members from ClassNK, Kobe Steel, and the purchaser of the compressor, conducted material tests to ensure the suitability of the materials used in the ultra-low temperature hydrogen environment, identified various issues and preconditions required for the qualification process, and performed risk assessments.

Through these verifications, the safety and reliability of the ultra-low temperature hydrogen reciprocating compressor required for the qualification of Step 2 was confirmed by the team and endorsed by the Statement. This acknowledgement will provide customers with assurances regarding the equipment.

The Kobe Steel Group (also known as the Kobelco Group) is working on the transformation into an appealing company, as set out in its Medium-Term Management Plan (Fiscal 2024–2026). As part of this effort, we are advancing an initiative called KOBELCO-X, which spans a wide range of transformations, including this one classified as green transformation (GX)—Contributing to decarbonization in hydrogen plants for the maritime shipping and onshore industries through the development of ultra-low temperature hydrogen reciprocating compressor.

Our Group’s current Medium-Term Management Plan also aims to take on the challenge of realizing carbon neutrality as one of its priority issues, and we believe the ultra-low temperature hydrogen reciprocating compressor will help us reach this goal. We will continue to provide solutions to the needs of society through the supply of ultra-low temperature hydrogen reciprocating compressor units to the maritime shipping industries and onshore hydrogen plants while utilizing new technologies, as we strive to realize a world in which people, now and in the future, can fulfill their hopes and dreams while enjoying safe, secure, and prosperous lives.

*1: Statement of Feasibility for Technology Qualification is a certificate stating that the technology satisfies the requirements of the Technology Qualification Guidelines (Version 1.0). Technology Qualification verifies and proves that new technologies that are outside the scope of the existing ClassNK rules for the survey and construction of steel ships meet the specifications proposed by the applicant through testing based on an agreed plan. Kobe Steel’s ultra-low temperature hydrogen reciprocating compressor has completed the second of the four steps.

*2: Technology qualification process consists of the following four steps

(Note) The information on this web site is presented "as is." Product availability, organization, and other content may differ from the time the information was originally posted. Changes may take place without notice.