April 24, 2025

Kobe Steel, Ltd.

Kobe Steel, Ltd. announces that its low-CO2 blast furnace steel product Kobenable® Steel has been selected by Isuzu Motors Limited as part of steel sheet products used in its light-duty tuck ELF and other models. Employed is Kobenable® Premier, which reduces 100% of CO2 emissions in steel production based on the mass balance method*1.

ELF Diesel: Photo courtesy of Isuzu Motors

Kobenable® Steel, developed by Kobe Steel using its original CO2 reduction solution for blast furnace ironmaking*2, is available for all types of steel products (steel sheets, steel plates, wire rods and bars) manufactured at the Company’s Kakogawa Works and Kobe Wire Rod & Bar Plant. In addition, since it maintains the same level of high quality as conventional products, customers can use low-CO2 blast furnace steel for products that require high quality, such as special steel wire rods and ultra high-tensile strength steel, which are Kobe Steel’s specialties.

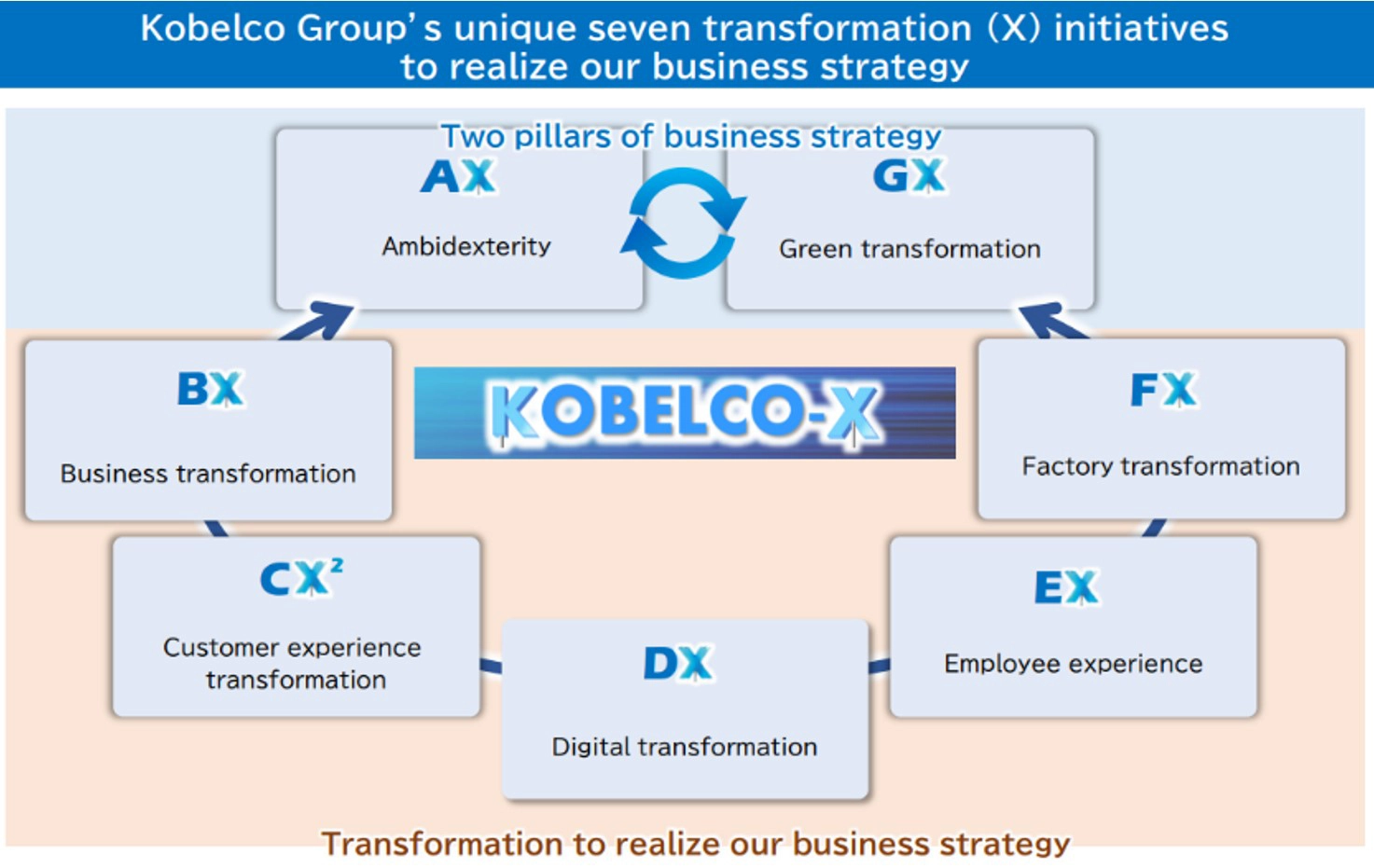

The Kobe Steel Group (also known as the Kobelco Group) is working on the transformation into an appealing company, as set out in its Medium-Term Management Plan (Fiscal 2024–2026). As part of this effort, we are advancing an initiative called KOBELCO-X*3, which spans a wide range of transformations, including this one classified as green transformation (GX)—Contributing to decarbonization by providing the low-CO2 blast furnace steel product for the automotive industry.

Our Group’s current Medium-Term Management Plan also aims to take on the challenge of realizing carbon neutrality as one of its priority issues, and we believe that promoting the use of the low-CO2 blast furnace steel product Kobenable® Steel will help us reach this goal. The Group will continue to work for providing solutions to the needs of society by integrating its diverse businesses, technologies and human resources in a unique way and will move forward with its transformation initiatives in order to become a more appealing company to all of its stakeholders with a view to a world in which people, now and in the future, can fulfill their hopes and dreams while enjoying safe, secure, and prosperous lives.

*1 Mass-balance method:

Steelmakers allocate their CO2 reductions to a certain portion of products by receiving a certificate for their CO2 reductions in accordance with the Guidelines for Green Steel, established by the Japan Iron and Steel Federation (JISF). The items that have been allocated CO2 reductions are classified as steel products with low-CO2 emission intensity.

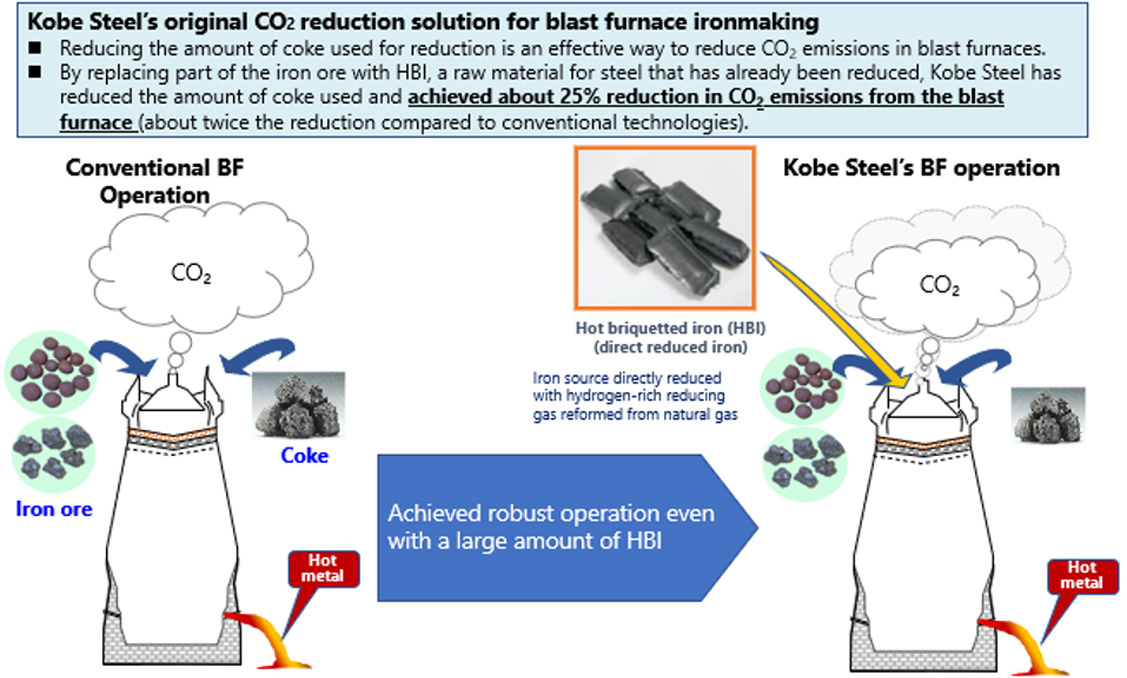

*2 Kobe Steel’s original CO2 reduction solution for blast furnace ironmaking:

This technology, demonstrated at Kobe Steel’s production site Kakogawa Works, achieves a significant reduction of CO2 emissions from the blast furnace by charging into the blast furnace a large amount of hot briquetted iron (HBI) manufactured via the MIDREX® Process, a direct reduced ironmaking process, which accounts for about 80% of the world’s natural gas-based direct reduced iron (DRI) production (60% of the world’s overall DRI production). It can reduce CO2 emissions in the blast furnace ironmaking process by 20–40%.

*3 KOBELCO-X:

KOBELCO-X is a collective term for seven transformation initiatives that the Kobelco Group is promoting to transform into an appealing company.

| Categories | CO2 reduction rate per ton (compared to 2018 levels) |

|---|---|

| Kobenable® Premier | 100% |

| Kobenable® Half | 50% |

(Note) The information on this web site is presented "as is." Product availability, organization, and other content may differ from the time the information was originally posted. Changes may take place without notice.