See below for details about our management structure.

The Kobelco Group identifies environmental risks in its business activities and takes steps to reduce these risks, while properly managing risks in accordance with daily operating procedures. Through environmental audits and other activities, the Group continues to ensure thorough compliance with laws and regulations and reinforces environmental management.

We have set the following two targets in the Medium-Term Management Plan (Fiscal 2021–2023):

The Group conducts paper-based audits based on checklists of risks for each business location every year to ensure compliance with laws and regulations at Kobe Steel and all business locations of domestic Group companies.

On-site environmental audits had been conducted regularly at 11 business locations of Kobe Steel and 25 business locations of 17 domestic Group companies with high environmental risks. These are strict on-site environmental audits to check documents, such as measurement records and various reports, and inspect work sites for waste storage and other conditions. The audits also entail interviews with personnel in charge.

We implement on-site environmental audits regularly once every two to five years at overseas Group companies. During these audits, the environmental manager at the regional headquarters, who is well-versed in local laws and regulations, or a local consultant is appointed to review compliance with environmental laws and regulations as well as to reduce risks.

A total of 28 overseas Group companies are subject to on-site environmental audits: 6 in the United States, 9 in China, 12 in Asia excluding China, and 1 in Europe (as of April 2023). During on-site environmental audits, we grasp the actual state of environmental management and identify problem areas locally on-site, based on which necessary corrective measures are undertaken

In fiscal 2022, we conducted paper-based environmental audits of all the Group’s business sites, including non-production sites in Japan, and conducted on-site environmental audits at 13 production sites to confirm the status of environmental management. As for overseas Group companies, we conducted on-site environmental audits of 18 companies in Vietnam, Malaysia, the United States, China, and India.

At Company business locations and Group companies in Japan, there were four cases where air quality values exceeded regulation standards, and one case where water quality values exceeded regulation standards. All the cases were discovered by self-inspections and reported promptly to relevant authorities, with actions taken. No fines or punishments were imposed.

Overseas Group companies were fined 148,000 yuan (approximately 3 million yen) for violating paint storage standards. They also incurred fines of 30,000 yuan (approximately 900,000 yen) for exceeding water quality regulations.

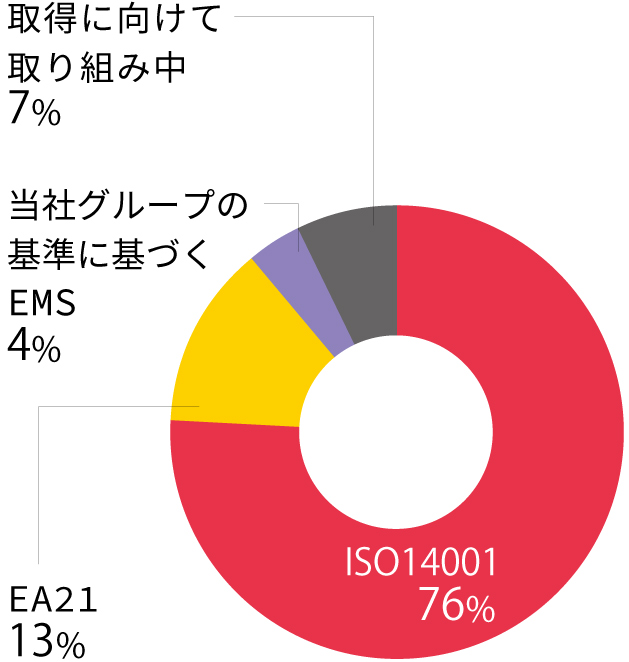

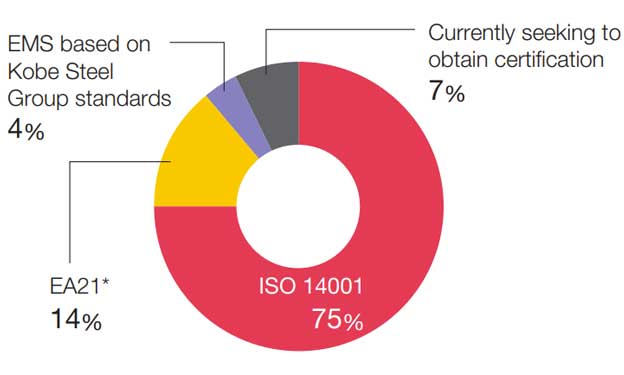

The Kobelco Group employs environmental management systems (EMS) based on ISO 14001 and reinforces environmental management through a plan-do-check-act (PDCA) cycle. At Kobe Steel, Ltd., certifications were obtained at all 11 locations (an integrated certification for Fujisawa Plant, Ibaraki Plant, Saijo Plant, and Fukuchiyama Plant) and the Engineering Business, with 17 Group company locations in Japan and 11 Group companies overseas having also obtained certification. The percentage of locations that have obtained certification for environmental management systems at all 44 main production sites is 89%.

* Environmental Activity Evaluation Program (Eco-Action 21):

A certification and registration program formulated by the Ministry of the Environment, for more accessible environmental management systems based on ISO 14001.

Each business location periodically conducts drills for possible emergency situations. Issues are identified in follow-up meetings after the drills and steps are taken to improve responsiveness.

Our overseas business locations also have environmental management structures in place, just like our business locations and Group companies in Japan. Kobe Steel aims to further strengthen environmental management by sharing information among business divisions at Kobe Steel and with overseas business locations.

In the United States and China, where many Group production sites are located, the regional headquarters for respective regions, Kobe Steel USA Inc. and Kobelco (China) Holding Co., Ltd., have environmental managers who are well-versed in local laws and regulations to assist other Group companies and take steps to mitigate risks.

The Kobelco Group established systems for checking compliance with environmental laws and regulations as well as environmental risks associated with investment projects at each business location. In addition, we employed an environmental checklist system through which the head offices double-check the laws and risks pertaining to projects that entail particularly large investments.

These checks are to confirm that, for example, chemical storage tanks are not installed underground in order to prevent soil contamination and check whether or not effective measures are in place for preventing leaks in cases when storage tanks are located near drainage channels.

We are working to improve environmental awareness through Eco-Office activities to create an energyefficient and comfortable work environment and to sustain environmental education/learning to enable all employees to take action for the environment.

The Group’s targets in the Medium-Term Management Plan (Fiscal 2021–2023) involve raising environmental awareness by continuing measures such as stratified training, e-learning, and environmental training for Group companies, as well as encouraging the use of the Kobelco Eco-Life Notebook.

As for results in fiscal 2022, we increased employees’ environmental awareness and knowledge through the Kobelco Group Environmental Conference, stratified training, and e-learning. Also, we promoted environmental awareness among employees in their home lives through the Kobelco Eco-Life Notebook.

The Kobelco Group Environmental Conference is held every year for the purposes of sharing environmental information and promoting crossdivisional environmental initiatives. In fiscal 2022, participants confirmed their commitment to steadily make efforts toward Kobe Steel’s carbon-neutral strategy, shared useful examples of ways to reduce the environmental burden at the business locations where they work, and reviewed changes to environmental laws and regulations.

Since fiscal 2006, we have continually incorporated environmental training and study into our stratified training program for employees in specific positions at respective business locations. Additionally, we provide e-learning programs regularly via the intranet.

In fiscal 2022, we provided stratified education and e-learning on compliance with environmental laws and regulations, environmental management, and “Taking on the Challenge of Realizing Carbon Neutrality by 2050.”

In the United States and China, we hold environmental seminars and networking events for employees in charge of environmental management at Group companies in order to advance their skills and share information on the latest developments in environmentrelated laws and regulations. Employees who will be transferred to overseas business locations are given environmental training prior to their departure with the aim of heightening the consciousness of environmental risks, ensuring compliance with local laws and regulations, and preventing environmental problems.

In order to strengthen environmental management and raise environmental awareness, we are encouraging employees to acquire environmental qualifications (such as for pollution control managers or qualified persons for energy management).

Employees Acquiring Environmental Qualifications in Fiscal 2022 (Kobe Steel, Ltd.)

(Persons)

| Qualification | Number of Qualified Personnel |

|---|---|

| Pollution Control Manager (Air) | 295 |

| Pollution Control Manager (Water) | 237 |

| Pollution Control Manager (Noise/Vibration) | 162 |

| Pollution Control Manager (Dust) | 50 |

| Pollution Control Manager (Dioxins related) | 66 |

| Pollution Control Chief Manager | 3 |

| Qualified Person for Energy Management | 258 |

| Certified Environmental Measurer | 19 |

The Kobelco Group actively discloses environmental information to communicate its environmental management initiatives to stakeholders. At our business locations, we work on environmental communication, including regularly holding dialogue with community members.

The Kobelco Group set targets in the Medium-Term Management Plan (Fiscal 2021–2023) to continue initiatives such as the disclosure of information in an effort to communicate with all stakeholders.

In fiscal 2022, we disclosed environmental information via our integrated report, ESG data book, corporate website, public monitors, and other measures. Also, we set up booths at various exhibitions and introduced our Group’s environmental technologies and products.

We disclose environmental information as important non-financial information.

In order to gain the understanding of community members in the area of Kakogawa Works, the Kobe Wire Rod & Bar Plant, and the Kobe Power Plant regarding our environmental preservation efforts, we regularly hold information sessions. (In fiscal 2022, information sessions on the Kobe Wire Rod & Bar Plant and Kobe Power Plant were canceled to prevent the spread of COVID-19.)

Toll-free phone numbers (only available in Japan) have also been set up at Kakogawa Works and the Kobe Wire Rod & Bar Plant to answer environment-related inquiries. We will continue to value the opinions of local community members.

Kakogawa Works and the Kobe Wire Rod & Bar Plant (including the Kobe Power Plant) provide realtime information on the environment, including soot and smoke emissions from the steelworks, through monitors set up in various locations.

| Locations of Public Monitors | |

|---|---|

| Kakogawa Works environmental information | Kakogawa City Hall, Harima Town Hall, and local community centers in Befu and Onoe, both in Kakogawa |

| Kobe Wire Rod & Bar Plant environmental information (including Kobe Power Plant) |

Nadahama Science Square, Nadahama Garden Baden |

The Group is making efforts to reduce its environmental impacts.

We disclose information to better grasp the costs and benefits associated with our environmental conservation activities, and to deepen stakeholder understanding of our efforts.

Kobe Steel, Ltd. invests in the installation and continual maintenance of environmental equipment and pursues environmental measures on a variety of fronts.

In fiscal 2022, we invested approximately 1.12 billion yen in facilities to reduce CO2 emissions and prevent air and water pollution.

Expenses for environment related operations in fiscal 2022 totaled 44.0 billion yen.

Moreover, we invested about 26% of total expenses, or roughly 11.6 billion yen, in research and development for technology development, including making automobile weight-reduction proposals that combine competitiveness of cutting-edge materials such as high-tensile strength steel and aluminum with automotive solution technologies, demonstrating our strengths as a company that operates steel, aluminum, and welding businesses. Of these, we invested approximately 3.6 billion yen as R&D expenses related to climate change.

We will continue to implement measures to reduce environmental impacts.

(Millions of yen)

| Item | Fiscal 2020 | Fiscal 2021 | Fiscal 2022 | |||||

|---|---|---|---|---|---|---|---|---|

| Capital investment |

Expense | Capital investment |

Expense | Capital investment |

Expense | |||

| Expenses in business areas |

Environmental expenses |

Air pollution prevention | 2.1 | 76.1 | 2.2 | 90.9 | 6.2 | 112.9 |

| Water pollution prevention | 2.1 | 39.4 | 0.8 | 46.6 | 1.5 | 54.9 | ||

| Resource recycling expenses |

Waste recycling/processing, yield improvement |

0.1 | 89.5 | - | 94.0 | - | 128.1 | |

| Climate- related expenses |

Energy-saving investment | 12.3 | - | 3.5 | - | 3.5 | - | |

| Management activities expenses |

EMS registration/renewal | - | 0.4 | - | 0.4 | - | 0.4 | |

| Environmental impact monitoring/measuring | - | 2.5 | - | 2.8 | - | 4.6 | ||

| Personnel expenses for environmental measures/organization |

- | 18.8 | - | 19.3 | - | 19.4 | ||

| R&D expenses |

Development of eco products and reduction of environmental impact of manufacturing processes |

- | 89.6 | - | 102.6 | - | 116.4 | |

| Of which, R&D related to climate change |

- | 45.1 | - | 47.6 | - | 35.7 | ||

| Social activities expenses |

Environmental organization support, advertising | - | 0.1 | - | 0.1 | - | 0.2 | |

| Other expenses |

Pollution levy | - | 3.0 | - | 2.8 | - | 3.5 | |

| Total | 16.6 | 319 | 6.5 | 360 | 11.2 | 440 | ||