To make effective use of limited resources, the Kobelco Group implements measures to control waste. We add value to by-products created during manufacturing processes, develop and introduce new applications for materials, and actively pursue recycling. The Group also reduces paper consumption by reviewing packaging specifications for products to be shipped for the reuse of packaging/shipping supplies, and by actively promoting digitization and IT adoption in documents used at office work across the entire Group. Additionally, we have set recycling targets for the main forms of waste, and are seeking to improve the recycling rate in order to reduce the final disposal amount.

See below for details about our management structure.

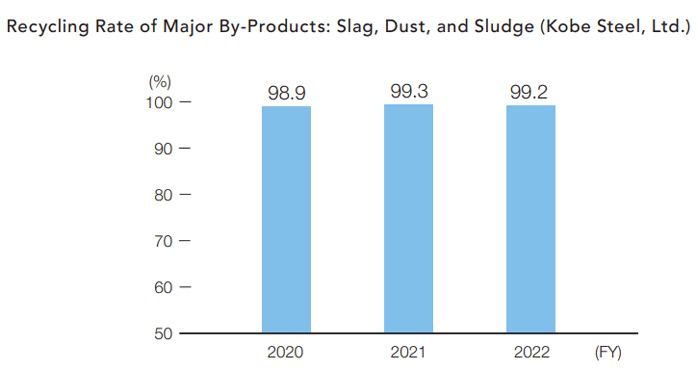

We actively promote yield improvement and reduction of auxiliary material consumption. We have set the fiscal 2025 target of achieving a recycling rate of 99% for major by-products (slag, dust, and sludge).

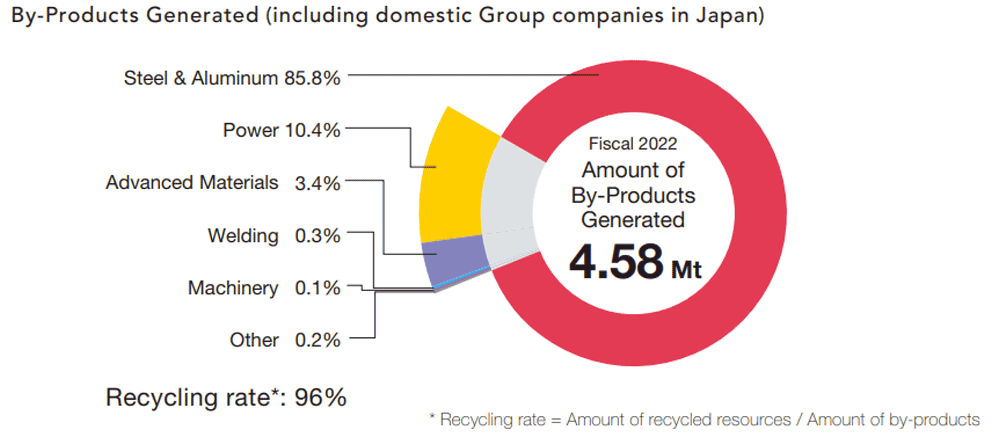

In fiscal 2022, a total of 4.58 million tons of by-product materials were generated by the Kobelco Group* and the recycling rate was 96%. We will continue to reduce final landfill disposal volume by controlling the amount of by-products produced, increasing recycling, and developing new recycling technologies and offering added value.

* The information above covers 99% or more of the amount of waste generated by the Kobelco Group in Japan.

Among this, the recycling rate of major by-products (slag, dust, and sludge) in fiscal 2022 was 99.2%, achieving the target. We will continue to work on raising the recycling rate of by-products and reducing final disposal amounts in order to achieve these targets.

| Fiscal 2020 | Fiscal 2021 | Fiscal 2022 | |

|---|---|---|---|

| Amount of by-products (t) | 3,188,926 | 4,051,021 | 4,576,542 |

| Amount of recycled resources (t) | 3,021,888 | 3,901,504 | 4,441,651 |

| Amount of landfill disposal (t) | 135,923 | 119,932 | 124,363 |

| Other (volume reduction, t) | 31,115 | 29,585 | 40,528 |

| By-product recycling rate2 | 95% | 96% | 96% |

| Amount of specially controlled industrial waste generated |

23,949 | 21,136 | 19,597 |

| Amount (rate) of specially controlled industrial waste generated (%)3 | 0.75% | 0.52% | 0.43% |

1 The information above covers more than 99% of the waste generated by the KOBELCO Group in Japan.

2 By-products (total) recycling rate = Amount of recycled resources / Amount of subject to treatment

3 Rate = Amount of specially controlled industrial waste generated / Amount of by-products generated

| Fiscal 2020 | Fiscal 2021 | Fiscal 2022 | |

|---|---|---|---|

| Transportation amount of specially controlled industrial waste (t) |

15,656 | 16,935 | 15,333 |

* Amount of specially controlled industrial waste for which processing is outsourced

| Main Raw Materials | Unit | Fiscal 2020 | Fiscal 2021 | Fiscal 2022 |

|---|---|---|---|---|

| Iron ore | 10,000 t | 931 | 1,047 | 933 |

| Coking coal/coke | 10,000 t | 492 | 534 | 497 |

| Aluminum ingots, copper ingots, etc. | 10,000 t | 43 | 49 | 46 |

| Total | 10,000 t | 1,466 | 1,630 | 1,475 |

Note: The totals may not match as a result of rounding.

Of the by-products produced, steel slag, which is produced in large amounts, is recycled more than 99% into construction and other materials, thereby contributing to a recycling-oriented society. Most steel slag products are designated as specified procurement items under the Act on Promoting Green Procurement for public work projects as materials that benefit environmental conservation. Going forward, we will continue to expand the applications of steel slag products that contribute to carbon neutrality and biodiversity.

| Application | Details |

|---|---|

|

Granulated blast furnace slag is pulverized and mixed into ordinary cement as a raw material for cement. This reduces CO2 emissions generated in the cement manufacturing process because the firing process of clinker, an intermediate product of cement, is no longer required. |

|

Roadbed material is made by pulverizing/granulating steel slag and ash stone. It has hydraulic properties and provides strong support. The roadbed material can contribute to conservation of the natural environment by being utilized as a substitute for natural resources. |

|

By replacing cement stabilizers with steel slag, it is possible to build a robust ground base at low cost, contributing to national resilience and reducing CO2 emissions during material manufacturing. |

|

Steel slag artificial stone is a form of artificial stone made by solidifying steel slag with cement. Steel slag is expected to make a contribution to absorb and hold CO2 by helping to restore marine resources by providing nutrients in the form of iron and other substances contained within the slag to encourage luxuriant seaweed growth. Steel slag is already being used in submerged bank construction work contracted by the City of Kobe. |

| Business Divisions | Examples of Initiatives to Reduce the Generation of By-Products/Waste and Decrease Landfill Disposal |

|---|---|

| Steel & Aluminum |

|

| Welding |

|

| Advanced Materials |

|

| Machinery |

|

| Power |

|

| Company Name | Examples of Initiatives to Reduce the Generation of Waste and Decrease Landfill Disposal |

|---|---|

| Kobelco Spring Wire (Foshan) Co., Ltd. (KSW) | Reuse of lubricants |

| Kobelco Automotive Aluminum Rolled Products (China) Co., Ltd. | Reuse of pallets used to transport products |

| Kobelco Aluminum Products and Extrusions, Inc. (KPEX) | Recycling of wooden pallets and sales of recyclable materials made of aluminum scrap |

| Thai Kobelco Welding Co., Ltd. (TKW) | Reuse of packaging materials and pallets |

| Kobelco MIG Wire (Thailand) Co., Ltd. (KMWT) | Reuse of packaging materials and pallets |

| Kobe Aluminum Automotive Products (China) Co., Ltd. (KAAP-C) | Reuse of aluminum scraps, etc., and conversion of packaging materials, resin pallets, hydraulic oil/ lubricant into recyclable materials |

| Kobe Aluminum Automotive Products, LLC (KAAP) | Reuse of aluminum balls for shot blasting and caustic soda |

| Initiative | Details |

|---|---|

| Initiatives to effectively use underutilized energy in local communities: From conversion of sewage sludge to fuel to hydrogen production and supply |

For more information, please see the following: |

| Study group for expanding usage of steel slag |

For more information, please see the following: |

| Demonstration project for gasification and methanolization of waste plastics |

For more information, please see the following: |

Based on the Act on Promotion of Resource Circulation for Plastics, we have set a goal of “strive to recycle target waste as much as possible (target: recycling rate of 80%).” We are aiming to achieve this by reducing the emission of used plastic products and industrial waste and outsourcing disposal to treatment companies that perform recycling and heat recovery. The recycling rate in fiscal 2022 was 79.6%. We will continue with our initiatives to control waste generation and recycling.