Home > Products > Energy & Chemical Field > Pressure Vessels > New Non-destructive Examination (TOFD SYSTEM)

New Non-destructive Examination (TOFD SYSTEM)

New Non-destructive Examination (TOFD SYSTEM)

HIGHLY RELIABLE UT TECHNIQUE-----TOFD UT SYSTEM

![]()

All the butt welds of high pressure vessels manufactured in accordance with ASME Sect. VIII.DIV.2 should be inspected by using RT for quality assurance. But recent ASME Code Case 2235 permits automatic UT in lieu of RT. Kobe Steel has developed the new automatic UT technique using TOFD (Time of Flight Diffraction) method and has been using for inspection of welds of heavy wall pressure vessels in lieu of RT.

Features of TOFD

![]()

- High Probability of Flaw Detection

- High Accuracy of Flaw Location Measurement

- High Accuracy of Flaw Sizing in Length

- Weld Integrity to be observed on CRT in Real Time as probes scan

- All inspection Data to be Digitised and Stored so that the Data can be Recalled and Processed for In-Service Inspection

What is TOFD?

![]()

The basic configuration for TOFD (Time Of Flight Diffraction) technique consists of a separate ultrasonic transmitter and receiver. After emission of a compressional wave from a transmitter, the first signal to arrive at the receiver is lateral wave through upper surface. In the absence of defects the second signal to arrive at the receiver is the backwall echo. The diffracted signal generated at the upper tip of a defect will arrive before the signal generated at the lower tip of a defect.

With a time of flight of each flight path, the ultrasonic velocity and the spatial relationships of the two probes, location and height of defects can be very accurately calculated.

Gray scale imaging techniques are applied to the RF(AC) signal phases and enable weld integrity to be observed in real time. The defects are shown like as shell pattern on CRT. A-scan signals are stored in the memory together with location signals.

TOFD System

![]()

TOFD system consists of computerized UT detector, transmitter, receiver, pream-plifier, encoder and cables.

TOFD system is small and light and is portable and accessible to inspection position.

Scanning and display on CRT

![]()

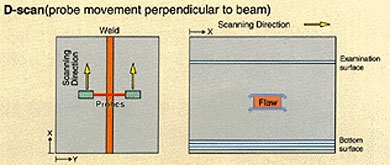

D-Scan

D-scan is non parallel scanning placing weldment at the center of the two probes.

Signals from the upper and lower tips of a defect are displayed on gray scale. D-scan and length and height of a defect can be accurately measured.

D-scan is the most popular scanning procedure for weldment.