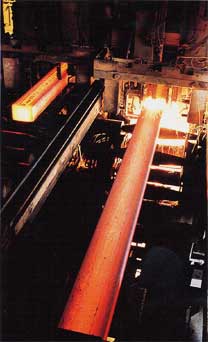

Continuous Casting

A combined electromagnetic stirring system in the mold and terminal stage of solidification is used in continuous casting to reduce inclusions and improve center segregation.

Solidification structure

improvement through

electromagnetic stirring

Without stirring

With stirring

The continuous casting process involves automation using computers, leading to the reduction of surface defect by in-mold surface level control with eddy current sensors and uniform cooling in a slab by misting.