October 5, 2016

Kobe Steel, Ltd.

The die-forging method enables Kobe Steel to supply high-strength, lighter weight components with an approved 5-percent margin in fatigue strength in the design phase. Having already received the same Class NK approval for small and medium-sized throws, Kobe Steel is the only company in the world to receive certification for the full range of throws, ranging from small to large, for use with two-cycle engines.

In addition, for rudder parts such as rudder horns and rudder stock, the fuel consumption of ships can be improved through narrower rudders by using higher-strength (and consequently thinner) components. For this field, Kobe Steel in 2013 developed cast steel that is 60 percent stronger than conventional cast steel. At this time, Kobe Steel has also developed high-strength cast steel that does not require heat treatment when welding rudder parts made of the material to the ship’s hull. This is anticipated to contribute to high-strength and thinner components, without hindering the welding process.

The marine industry currently faces an increasing need to improve fuel consumption due to stricter exhaust gas regulations and from the standpoint of increasing the energy efficiency of ship operation. The main ways to do this are to develop hull form designs that reduce drag and high-efficiency engines.

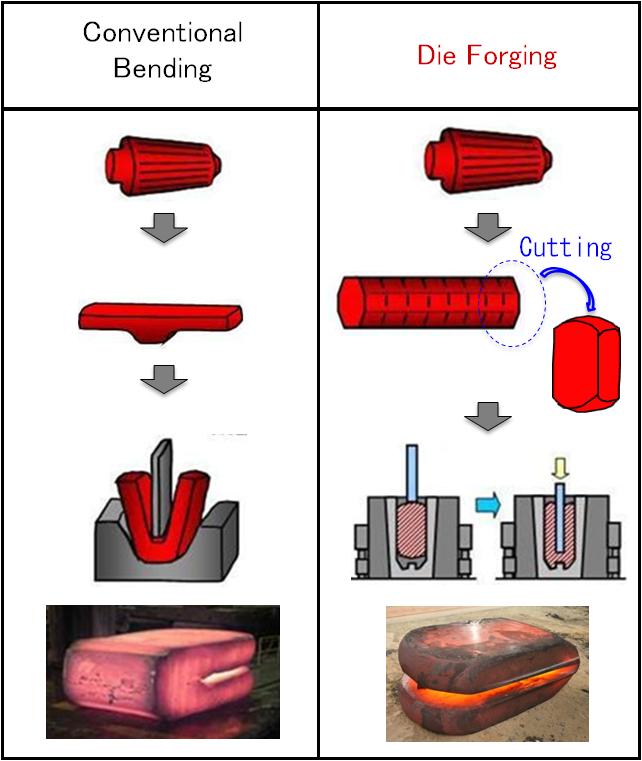

Kobe Steel has already developed a method of die forging that increases fatigue strength by approximately 20 percent, compared with the conventional method. In 2014, Kobe Steel received ClassNK certification for the manufacture of small and medium-sized crank throws using this process. The application of the same die-forging method to make large-sized throws encountered the issue of high binding force necessary during forging. Kobe Steel developed a mold with a new design configuration, along with low-sulfur steel with reduced nonmetallic inclusions, which contributed to ClassNK certification.

Kobe Steel plans to utilize its production technology for super clean steel to attain certification for higher K-factors.

In addition, to achieve further weight savings in built-up crankshafts, it is necessary to ensure the gripping strength (slip resistance property) of the throw and journal. In response, Kobe Steel developed a low-cost, low-alloy steel with a high yield point and created drawings of lightweight crank throws for current engines. In the future, Kobe Steel hopes to contribute to higher output and more compact engines, combining high fatigue strength utilizing the K-factor and its proprietary steel.

Rudder parts for ships such as the rudder horn need to be welded to the ship’s hull. To prevent welding defects during the welding process, high-strength material generally requires heat treatment (preheating and post-heating) during welding. By making fine adjustments to the component composition, Kobe Steel was able to develop a new cast steel in which welding defects do not occur even though heat treatment is omitted during the welding process. This development improves shipbuilding productivity and makes possible rudder parts of high strength.

Through innovative technology and product development, Kobe Steel contributes to energy savings in marine transportation and the further development of the shipbuilding industry.

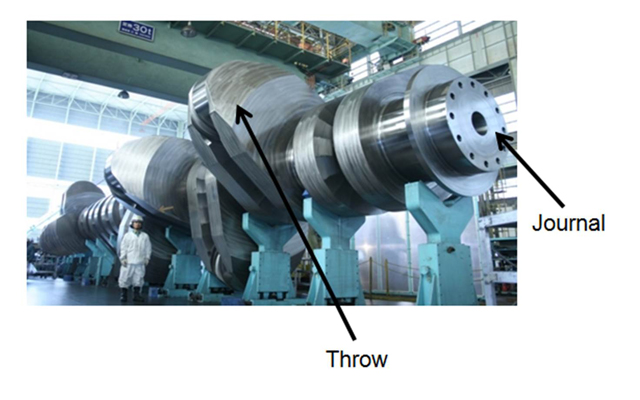

A crankshaft consists of a shaft portion called the journal and offset arms on the crank called throws. A crankshaft converts the reciprocating motion of the engine pistons to rotational motion of the shaft to transmit power to turn the propeller.

A method of forming the throw. In the die-forging method, the steel is shaped by forcing it into a die, resulting in a high-quality piece with no segregation and a 20-percent improvement in fatigue strength, compared with the conventional bending method of forging.

A coefficient used in calculating design fatigue strength. In comparison to a standard value of 1.0, Kobe Steel’s high strength forging is certified with a strength design of 1.05, providing a margin that can contribute to lighter and more compact forgings.

(Note) The information on this web site is presented "as is." Product availability, organization, and other content may differ from the time the information was originally posted. Changes may take place without notice.