February 24, 2021

Kobe Steel, Ltd.

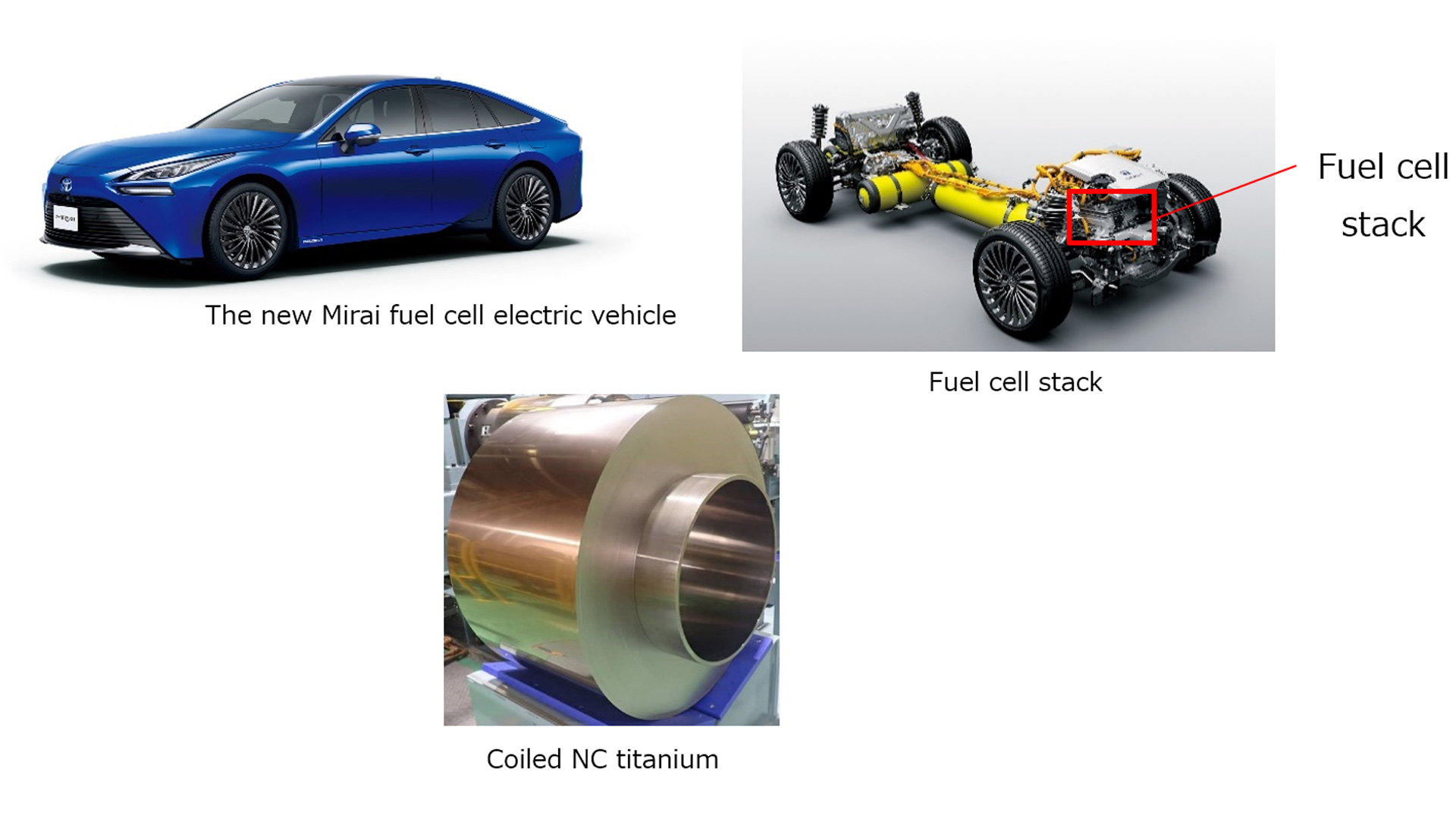

Kobe Steel, Ltd. announces that it has succeeded in the development and mass production of the world’s first nano-carbon composite coat titanium (NC titanium) *1).

The new titanium material was adopted by Toyota Motor Corporation for the latest model of Mirai fuel cell electric vehicle launched in December 2020. Kobe Steel received from Toyota the Project Award*2) in the category of 2020 model year FCEVs in recognition of the company’s superior technology that contributes to the enhancement of the product potential of the new Mirai.

NC titanium is used for separators*3) of the fuel cell stack*4), which is a power generator for FCEVs. The materials used for separators must have corrosion resistance, surface conductivity, and formability.

The KOBELCO Group has succeeded in developing NC titanium that meets these requirements by utilizing the synergy of its diverse businesses through a combination of titanium rolling material manufacturing and surface treatment technologies in the materials business and the vacuum surface treatment and related equipment technologies in the machinery business.

Titanium has superior corrosion resistance compared to other metal materials such as steel and aluminum. The specific gravity of titanium is about 60% that of iron, making it a very suitable metal material for the development of lighter vehicles. The main feature of NC titanium is that it has both high corrosion resistance and surface conductivity. NC titanium also has the formability to withstand press forming, and by applying NC surface treatment to the rolled strip in advance, surface treatment after press forming is not required. As a result, NC titanium contributes to the further downsizing and higher performance of fuel cell stacks, as well as the dramatic improvement in productivity at the customer’s production site.

The KOBELCO Group has elemental technologies and R&D facilities that can provide new value to society. We believe that it is our mission to contribute to creating a green society through our products, technologies and services with the aim of achieving carbon neutrality by 2050, as declared by the Japanese government. The KOBELCO Group has always strived to and will continue to provide solutions to the needs of society by making the best use of the talents of our employees and our technologies with a view to realizing a world in which people, now and in the future, can fulfill their hopes and dreams while enjoying safe, secure, and prosperous lives.

*1) Nano-carbon composite coat titanium (NC titanium), developed by Kobe Steel, is a rolled and surface treated titanium strip that combines the corrosion resistance, surface conductivity and formability required for fuel cell separators.

*2) Project Award is an award given to suppliers who have contributed to the enhancement of product competitiveness through their superior technologies, such as newly developed parts and materials used for the first time in a project undertaken by Toyota Motor Corporation and newly developed equipment and methods used for the first time in the manufacture of the vehicle.

*3) Separator is a plate-like component that plays the role of separating hydrogen gas and oxygen gas in the fuel cell. It provides a flow path with fine grooves that allow hydrogen and oxygen supplied as fuel gases to pass through, and it also serves to flow generated electricity.

*4) Fuel cell stack, a power generation device that generates electricity by reacting hydrogen gas and oxygen gas, is configured by combining a plurality of cells, which are the minimum power generation units containing a pair of separators. The new Mirai employs 330 cells.

Kobe Steel's special rolled titanium was also used for the separator of the first-generation Mirai, released in 2014. This special titanium rolled material had a problem of poor conductivity due to the oxide film on the surface of the material, which produces high corrosion resistance, and required the process of surface treatment to improve conductivity after press forming.

In addition to our existing technology for producing rolled titanium, Kobe Steel has newly employed its surface treatment and related equipment technologies to create a titanium oxide film with a surface layer containing dispersed nano-sized carbon as a conductor. In February 2014, the company succeeded in developing NC titanium, which is the most suitable material for the separator.

Since November 2014, Kobe Steel has jointly developed mass production technology for NC titanium with Toyota Motor Corporation. In the development of mass production technology, we applied the vacuum surface treatment technology developed by the Machinery Department of Kobe Steel to the NC titanium production process and devised Kobe Steel’s original continuous surface treatment equipment. By taking advantage of synergies in the materials and machinery businesses of Kobe Steel, we succeeded in the development of mass production technology.

(Note) The information on this web site is presented "as is." Product availability, organization, and other content may differ from the time the information was originally posted. Changes may take place without notice.