Advanced Materials

We maintain our leading position in Japan while pursuing weight reduction in automobiles, aircrafts, railway vehicles, vessels, and more.

Aluminum Forgings for Automotive SuspensionsMaterials Businesses

Top market share in Japan

Kobe Steel has the leading market share in Japan for aluminum forgings, which are over 40 percent lighter than conventional steel forgings.

Automotive aluminum extrusions and fabricated productsMaterials Businesses

Aluminum high-strength alloy

Bumpers and frame materials contribute to weight reduction of automobiles.

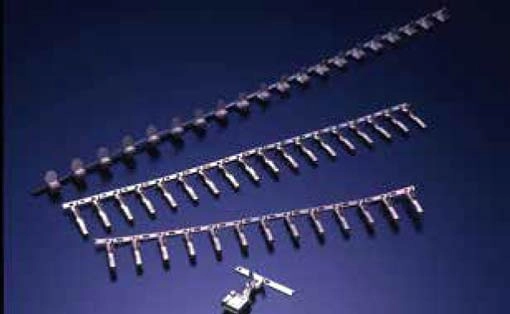

Copper Alloys and Plating for Automotive Terminals and ConnectorsMaterials Businesses

Top market share in Japan!

Copper alloys for automotive terminals and connectors are utilized in the wire harnesses often referred to as the nerves of an automobile. With about 30 percent of the market

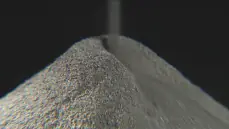

Steel PowderMaterials Businesses

Top market share in Japan

Used in automotive parts with complex shapes, and also manufactures products for environmental applications (for remediation of soil and groundwater contaminants).

Titanium for Aircraft Engine ComponentsMaterials Businesses

Titanium pioneer!

Kobe Steel has been delivering fan case components for aircraft engines for over 30 years

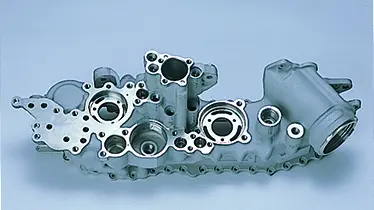

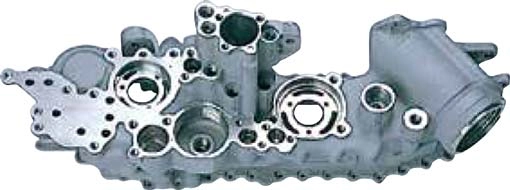

Aircraft GearboxesMaterials Businesses

Asia's only manufacturer to supply

Aircraft parts utilizing aluminum casting and forging technology, analysis techniques, and alloy development capabilities

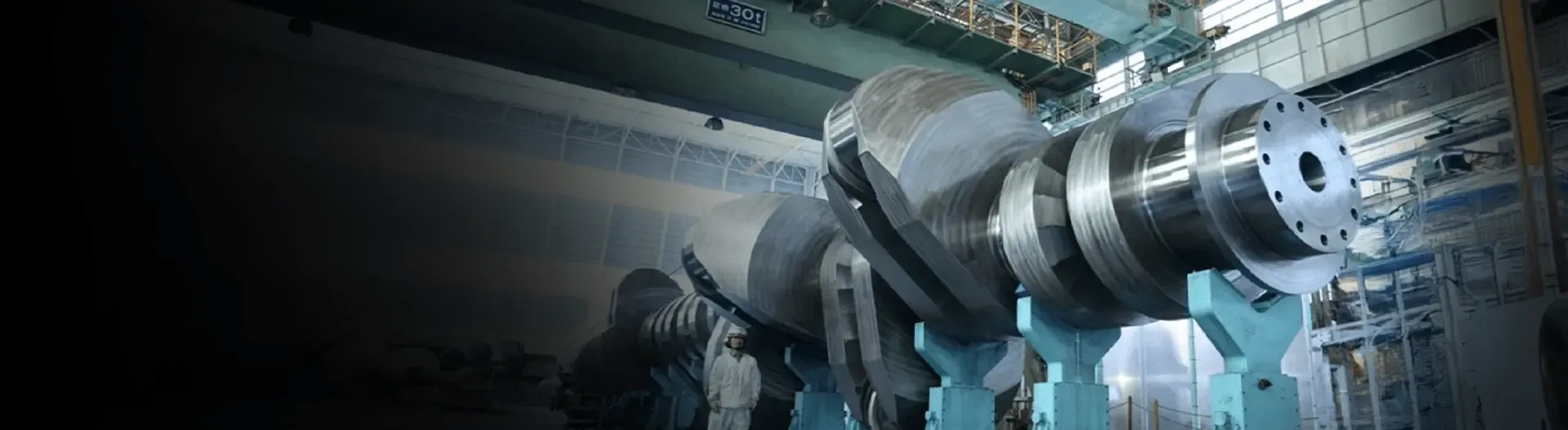

CrankshaftsMaterials Businesses

40% share of world market!

Kobe Steel holds 40 percent of the world market share for built-up and solid crankshafts

Aluminum Shapes for Rolling StockMaterials Businesses

Top market share in Japan

Aluminum shapes are used in the bodies of rolling stock.Recently, our aluminum shapes have been adopted in the UK.

Lead frame materials for semiconductorsMaterials Businesses

20% share of aisan market

Development ofcopper alloy materials and extends that combines strength, electrical conductivity, and heat resistance through a unique combination of elements

Basic Knowledge of Metal Advanced Materials

Locations & Group Companies

Contact Us

You can reach us by clicking the inquiry button.