In December 2020, Kobe Steel announced that it supports the recommendations of the Task Force on Climate-related Financial Disclosures (TCFD) and decided to join the TCFD Consortium, an organization of TCFD supporter organizations in Japan.

The Kobelco Group recognizes CO2 reduction as a top management priority. As such, we announced our aim to increase corporate value through a transition to carbon neutrality that we aim to achieve by 2050 in the Kobelco Group Medium- Term Management Plan (fiscal 2021–2023) announced in May 2021.

Going forward, the Kobelco Group will continue to pursue reduction of CO2 emissions in order to contribute to realization of “a world in which people, now and in the future, can fulfill their hopes and dreams while enjoying safe, secure, and prosperous lives” as envisioned in KOBELCO’s View of the Future.

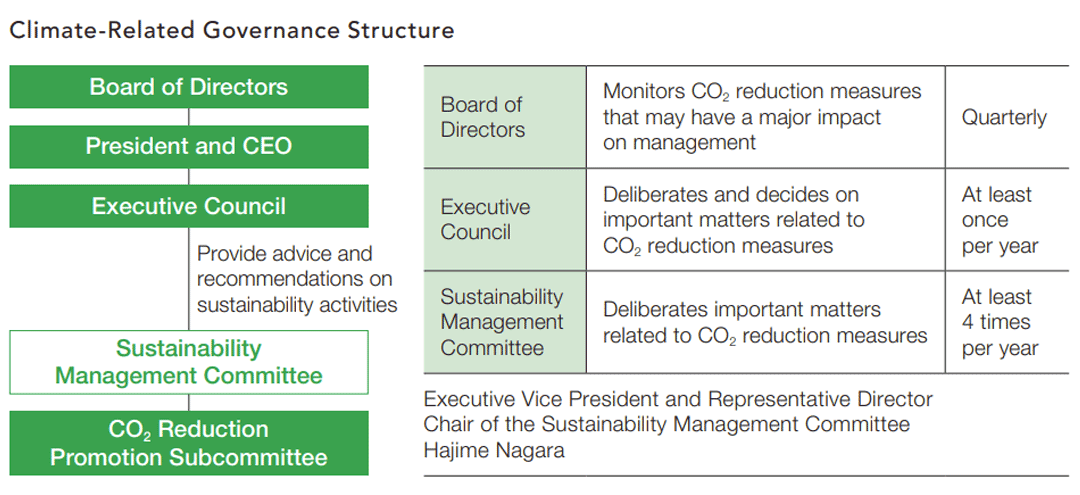

We established the CO2 Reduction Promotion Subcommittee under the Sustainability Management Committee (chaired by the Executive Vice President and Representative Director) as an organization that specializes in dealing with issues related to the risks and opportunities associated with climate change. The subcommittee, tasked with conducting strategic reviews of climate change, studies and implements Companywide activities to address the risks and opportunities of climate change.

Assessment and management of climate-related risks and opportunities are regarded as important management issues, and important decisions of the CO2 Reduction Promotion Subcommittee are subject to the approval of the relevant Executive Steering Committee. The Steering Committee consists of directors and executive officers, as knowledge from a wide range of perspectives and viewpoints is required for climate-related issues, including business, management, legal, and technological development.

The activities of the CO2 Reduction Promotion Subcommittee and its study outcomes are reported through the Sustainability Management Committee to the Board of Directors quarterly for supervision and guidance from the Board of Directors. Important decision-making related to climate change involves a system of direct governance by senior management. Under this system, recommendations are made to the Executive Council through the Sustainability Management Committee, with the matter then approved by the President and CEO or a resolution of the Board of Directors following deliberation by the Executive Council.

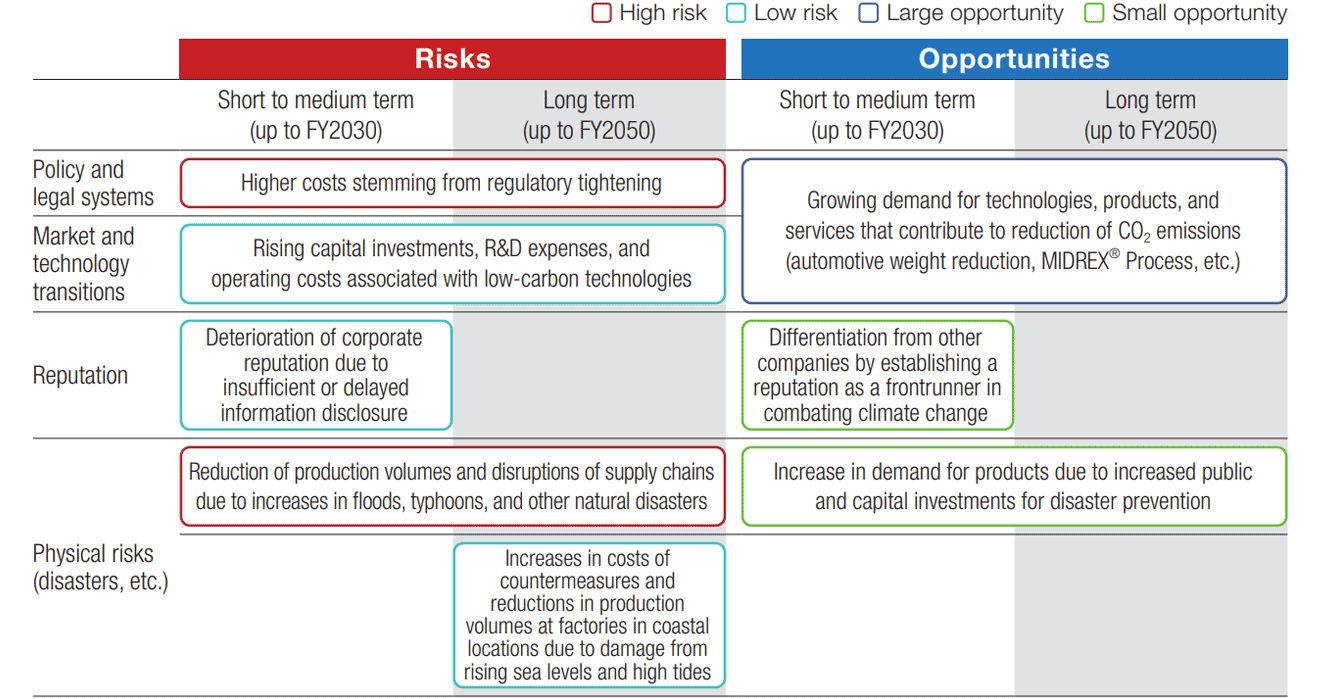

The Kobelco Group analyzes the medium- to long-term risks and opportunities associated with climate change considering various guidelines, including the social scenarios presented by the International Energy Agency (IEA); the long-term visions formulated and announced by the Japan Iron and Steel Federation, the Japan Aluminium Association, and other industry organizations; and the energy policies of Japan. Based on the analysis results, we evaluate the appropriateness of our Group’s activities.

According to the “Mandatory Greenhouse Gas Accounting and Reporting System (published by the Ministry of the Environment)”, Kobe Steel is one of the largest emitters of greenhouse gases in Japan. Our Company pays the carbon tax, Tax for Climate Change Mitigation (289 yen per ton of CO2 emissions from the use of coal, oil, LPG, and LNG), and in the future, if the carbon tax is increased or new taxes are imposed with the introduction of carbon pricing, it is expected to have a significant impact on our business, so we are constantly monitoring these trends. If regulations or taxes are imposed on CO2 and other emissions in the future, our Group’s business activities, particularly those related to steel, will be restricted, which may have an impact on our Group’s business performance with a decrease in sales, an increase in costs, etc.

The Kobelco Group has been promoting energy conservation efforts as a measure to mitigate the impact of carbon pricing. Our Group invested approximately 0.38 billion yen in energy conservation capital investments in fiscal 2022.

Examples of investments in fiscal 2022 include updating the blast furnace pneumatic cooler at the Kakogawa Works. For other initiatives, please refer to “Initiatives to Save Energy and Reduce CO2 Emissions” on page 26.

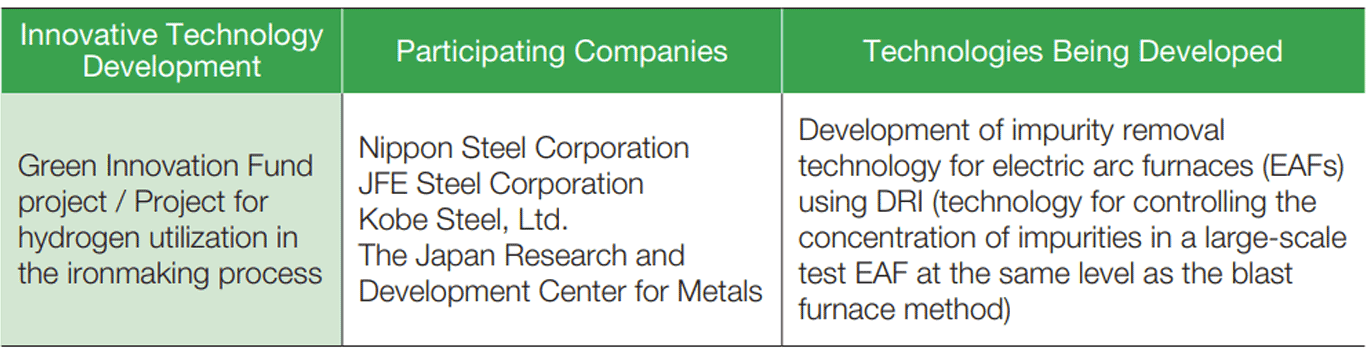

In addition, the Kobelco Group is engaged in the development of various technologies related to the reduction of CO2 emissions in production processes and contribution to reduction of CO2 emissions through technologies, products, and services in order to contribute to the reduction of CO2 emissions by society as a whole. In fiscal 2022, we spent approximately 3.6 billion yen on research and development related to climate change.

Detail is below:

In order to better understand future climate-related risks and opportunities, we carried out mediumterm (2030) and long-term (2050) scenario analysis.

Our scenario analysis is based on the International Energy Agency (IEA)’s 2°C scenario (SDS:Sustainable Development Scenario) and 1.5°C scenario (Net Zero by 2050) as well as the 4°Cscenario presented by the Intergovernmental Panel on Climate Change (IPCC) in its Sixth AssessmentReport. For our analyses and evaluations, we also refer to long-term visions published by industryorganizations to which we belong, such as the Japan Iron and Steel Federation (JISF) and the JapanAluminium Association. For the electric power business, which is closely related to Japan’s energypolicy, we conduct scenario analysis based on the energy policy of the national government. Wealso regularly review our analysis and evaluation of risks and opportunities based on changes in theexternal environment.

As more than 90% of our Group’s CO2 emissions come from the steelmaking process, the medium- to long-term trends in the steel industry will have the greatest impact on our business. According to the “JISF Long-Term Vision for Climate Change Mitigation—A Challenge towards Zero-Carbon Steel,” there is a certain correlation between economic growth and the amount of steel stock per capita. Therefore, the demand for steel is expected to continue to increase along with the world’s economic growth and population growth.

Steel production can be broadly divided into production with natural resources (iron ore, mainly using blast furnaces and DRI) and production with reused scrap (mainly using electric arc furnaces). According to JISF predictions, the reuse of scrap is expected to increase significantly due to the increase in the total amount of steel stock. On the other hand, demand for steel cannot be met by reused scrap alone. Accordingly, production using natural resources (iron ore) will continue to require the same level of production as at present.

Amid growing interest in the response to climate change and the disclosure of relevant information, the importance of CO2 reduction efforts in the iron and steel industry is expected to continue increasing. For this reason, we anticipate that our stakeholders, including national and local governments, investors, and customers, will pay greater attention to our efforts to reduce CO2 emissions from our own facilities and expand our environmental menu that contributes to CO2 reduction.

One of our Group’s core businesses is the manufacture and sale of steel products, which falls under the industry category of energy-intensive basic materials. Our Group’s CO2 emissions from energy use in fiscal 2022 totaled 15.6 million tons (Scope 1 and Scope 2), which ranks high even in Japan’s manufacturing industry. Accordingly, we recognize that the trends of future national climate change policies, laws, and regulations, including carbon pricing, are transition risks that may have a significant impact on our business operations.

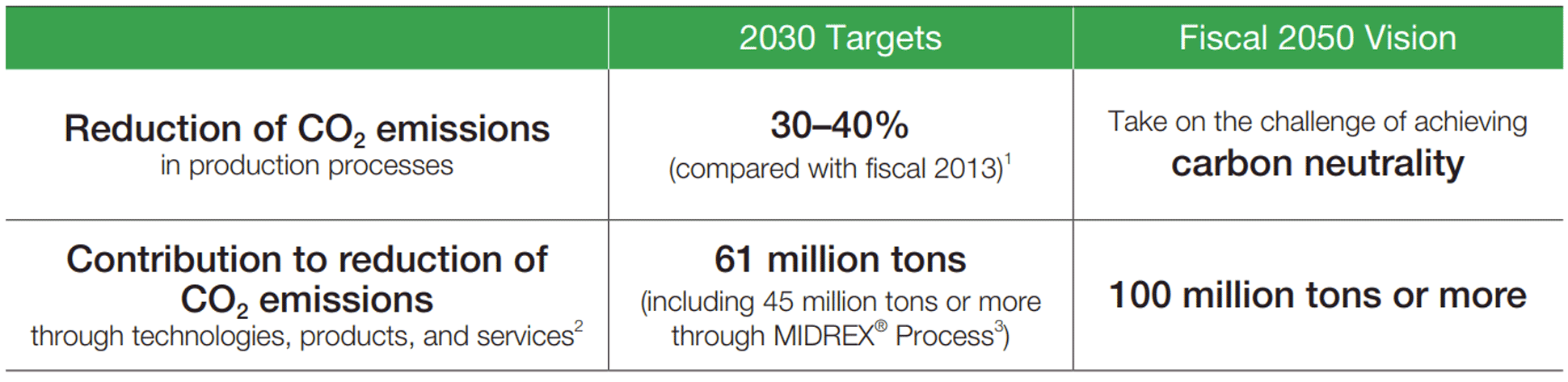

In May 2021, the Kobelco Group announced in its Medium-Term Management Plan (Fiscal 2021–2023) that it will take on the challenge of realizing carbon neutrality by 2050 and aim to increase corporate value through this transition. The Kobelco Group has set targets for 2030 and a vision for 2050 from two angles: (1) reducing CO2 emissions in the Group’s own production processes, and (2) contributing to the reduction of CO2 emissions through the Group’s distinctive technologies, products, and services.

Regarding the reduction of CO2 emissions in our own production processes, we will promote CO2 reduction initiatives and mitigate risks by formulating roadmaps for carbon neutrality in the ironmaking processes and in the electric power business. On the other hand, regarding the contribution to the reduction of CO2 emissions through the Group’s distinctive technologies, products, and services, we will make the most of opportunities by formulating a roadmap for the contribution to the reduction of CO2 emissions through the MIDREX® Process.

As for physical risks, the Japan Meteorological Agency (JMA) and various research institutes have reported that, as global warming progresses, the amount of precipitation tends to rise due to the increase of water vapor in the atmosphere, and damage caused by heavy rain and typhoons tends to become more severe. The risk of production stoppages and supply chain disruptions stemming from severe typhoons and heavy rains in recent years is also becoming more and more evident. Our Company recognizes that further intensification of typhoons, floods, and other natural disasters caused by climate change poses a risk that could have a significant impact on its operations and lead to suspension of production activities.

In accordance with its Risk Management Regulations, our Company has defined “climate-related regulations” and “natural disaster preparation and recovery” as Top Risks that are expected to have a particularly severe impact when an event occurs, with the aim of strengthening our risk management.

As for opportunities, demand for low-CO2 products and services is increasing amid growinginternational interest in climate-related issues. Along with this, we expect demand for products thathelp reduce CO2 emissions, such as our automotive weight-reduction materials and the MIDREX®Process, to grow over the medium to long term.

Targets and Vision Announced in the KOBELCO Group Medium-Term Management (Fiscal 2021–2023)

1 Most of the reduction targets are associated with iron and steel making processes.

We reviewed the targets announced in September 2020 (with the change from BAU to the total amount basis, and theincreased use of original solutions reflected).

Business As Usual (BAU): Emissions of greenhouse gases, or emissions per unit, assuming no additional measures are taken.

2 The KOBELCO Group contributes to the reduction of CO2 emissions in various areas of society through its distinctivetechnologies, products, and services.

3 Reviewed calculation formula announced in September 2020

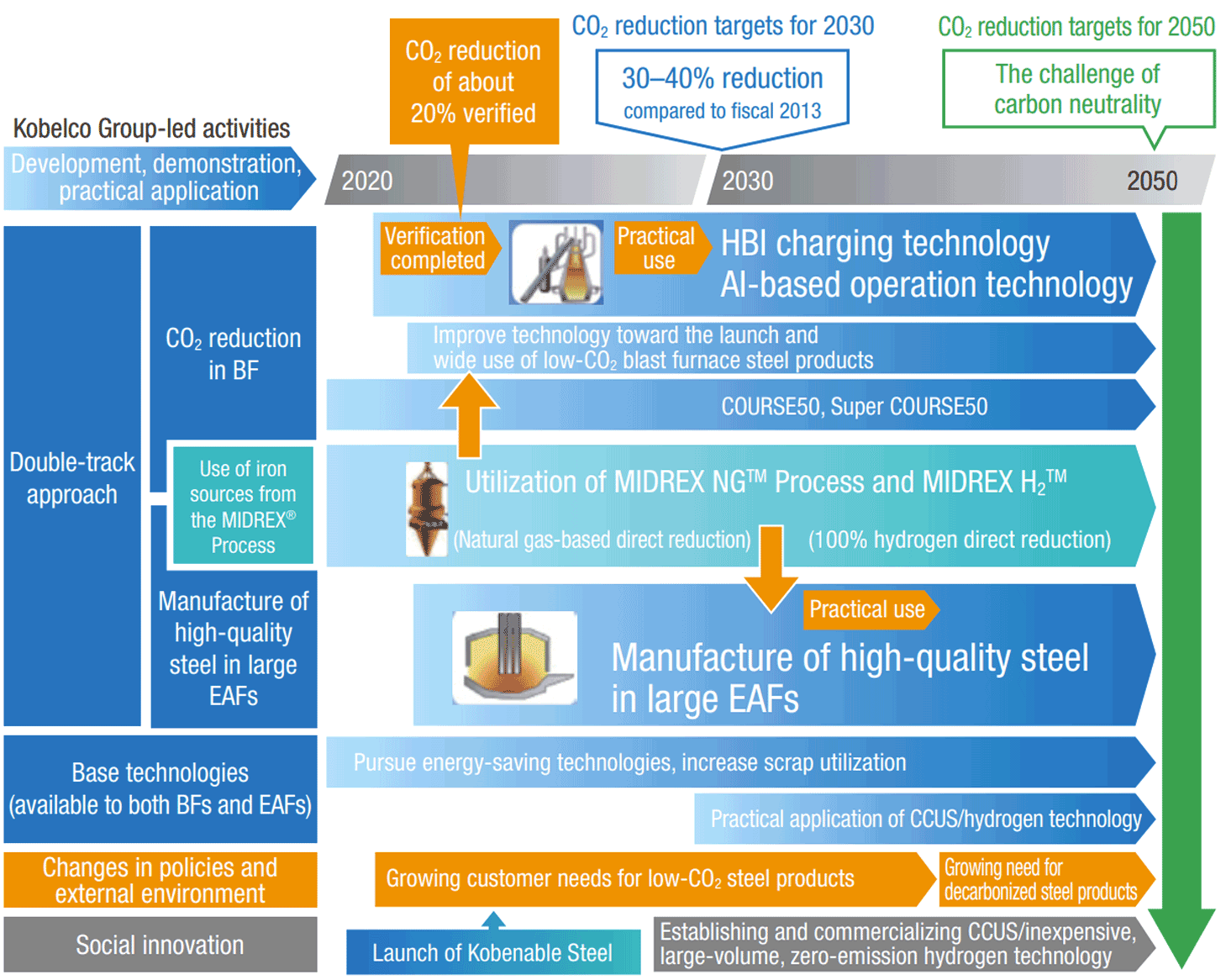

Roadmap for Carbon Neutrality in the Ironmaking Process

Roadmap for Carbon Neutrality in the Electric Power Business

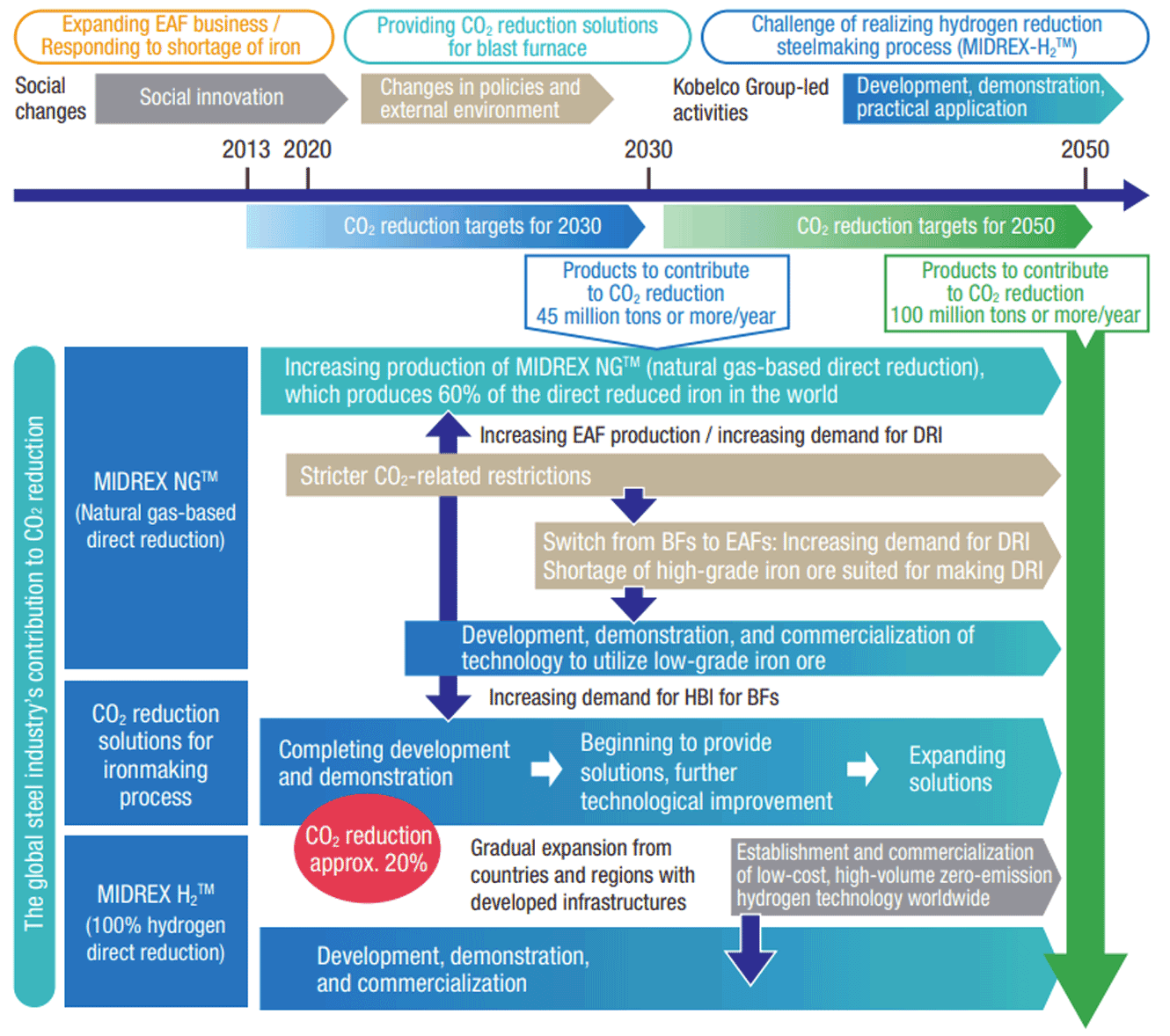

Roadmap for CO2 Reduction through the MIDREX® Process

In regard to climate-related risks, we have identified (1) transition risks (policies and regulations) and (2)physical risks (preparations for and recovery from natural disasters) as Top Risks, which are risks thatmay have a material impact on the Group and its stakeholders and require a Groupwide response. Weare working to strengthen risk management by appointing risk owners to each risk category.

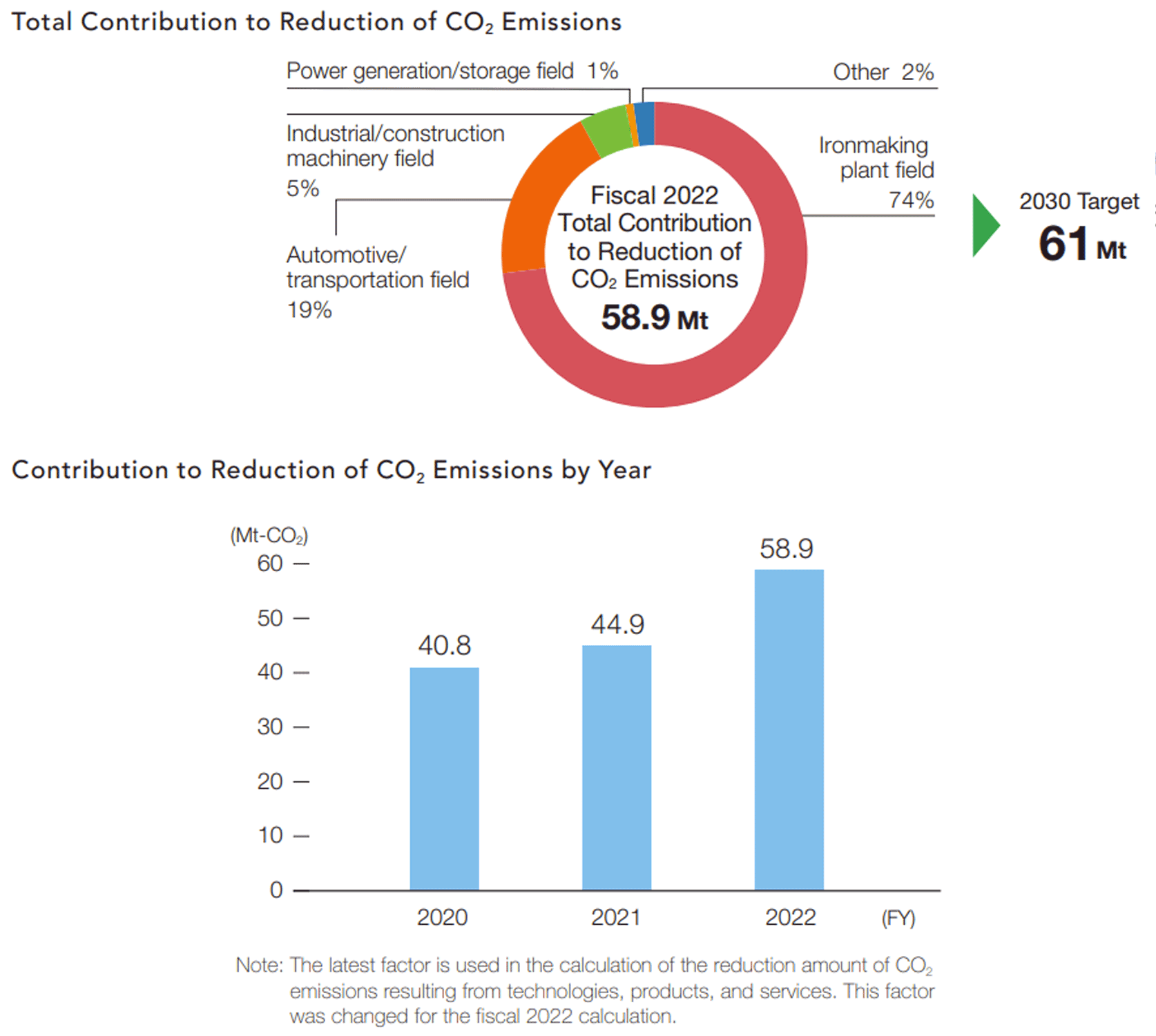

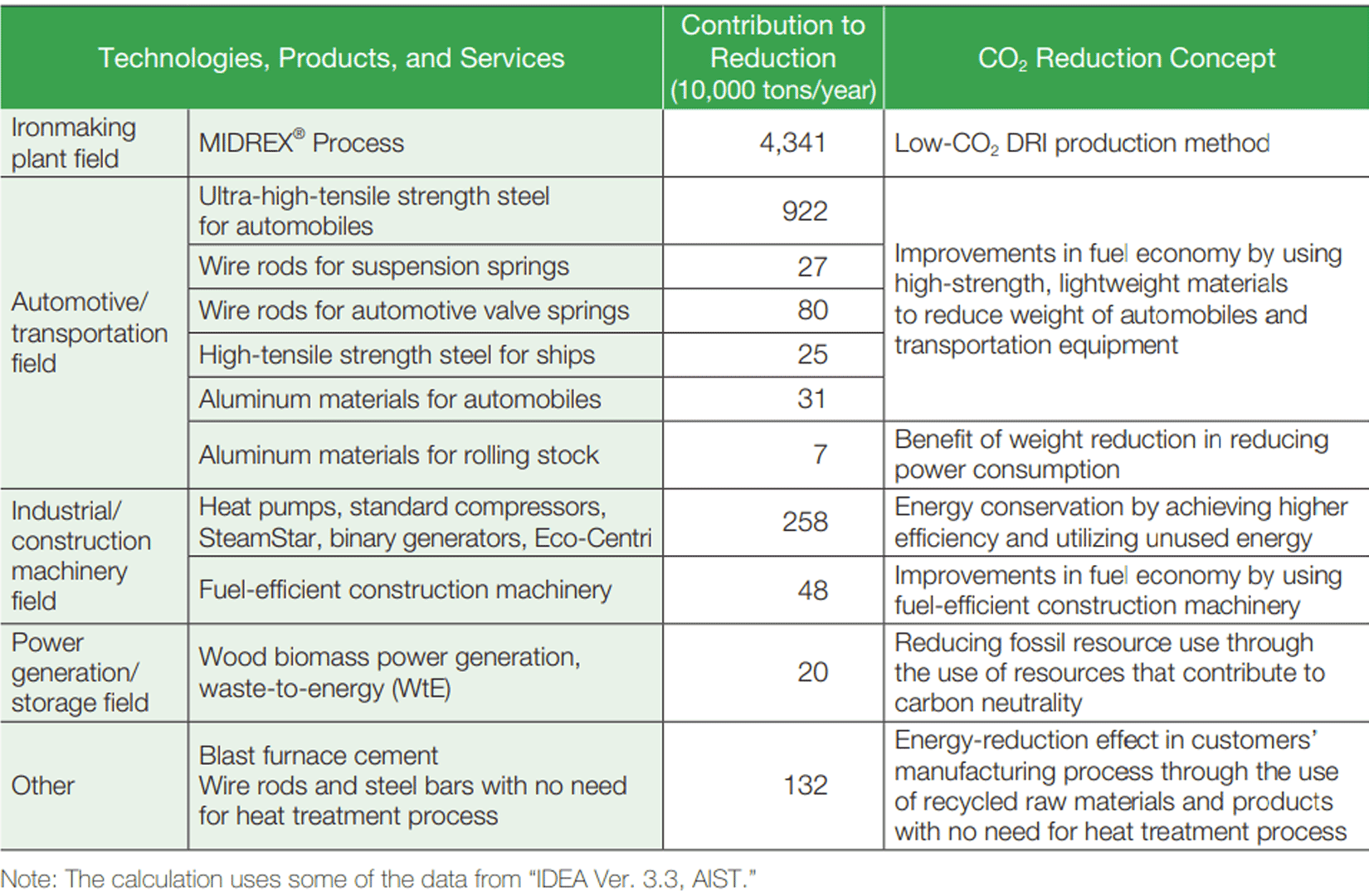

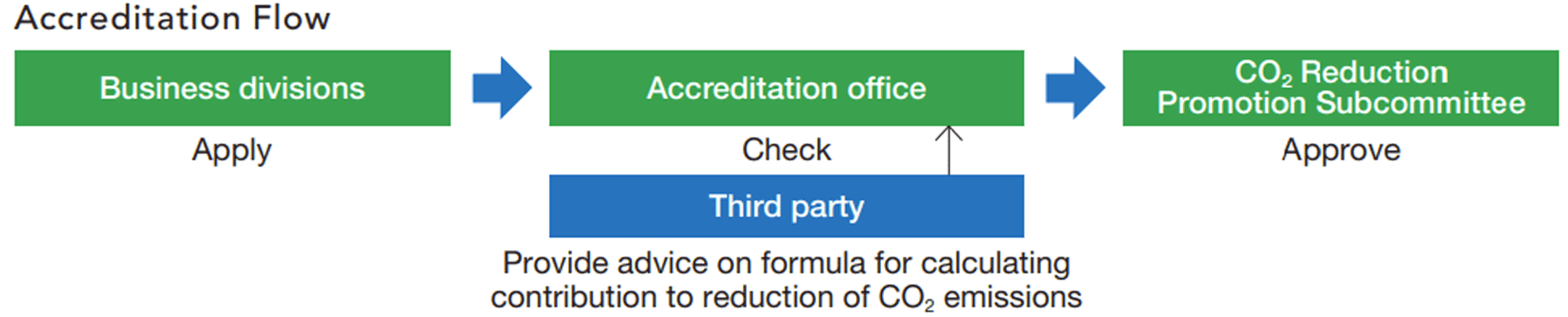

The Kobelco Group sets specific metrics for CO2 reduction activities, such as Reduction of CO2 Emissions in Production Processes (Metric A) and Contribution to Reduction of CO2 Emissions through Technologies, Products, and Services (Metric B), and sets and manages targets for each.

Kobe Steel positions these two metrics as non-financial key performance indicators (KPIs) and manages them. Non-financial KPIs including CO2 reduction are discussed annually at the Executive Council as important items in the budget, and then they are discussed and approved by the Board of Directors.

| Unit | Fiscal 2020 | Fiscal 2021 | Fiscal 2022 | |

|---|---|---|---|---|

| Energy consumption | PJ | 182 | 192* | 187✓ |

| Consolidated net sales | Million of yen | 1,705,566 | 2,082,582 | 2,472,508 |

| Energy intensity (per consolidated net sales) |

GJ / Million of yen | 107 | 92 | 75 |

| Products (crude steel, aluminum rolled products, copper rolled products) |

Million t | 6.3 | 7.2 | 6.7 |

| Energy intensity per t-product | GJ / t-Product | 28.7 | 26.6 | 27.9 |

Energy-Derived CO2 Emissions (Scope 1 and 2)

| Unit | Fiscal 2020 | Fiscal 2021 | Fiscal 2022 | |

|---|---|---|---|---|

| Scope 1 Emissions from the use of our own fuel (direct emissions) |

Million t-CO2 | 14.61 | 15.3 | 14.7✓ |

| Scope 2 Emissions associated with theuse of electricity, heat, and steam supplied by other companies(indirect emissions) |

Million t-CO2 | 0.8 | 0.9※1 | 0.9✓ |

| Scope 1+22 | Million t-CO2 | 15.41 | 16.1 | 15.6✓ |

| Consolidated net sales | Million of yen | 1,705,566 | 2,082,582 | 2,472,508 |

| CO2 emission intensity from energy use per net sales | t-CO2 /Million of yen | 9.0 | 7.81 | 6.3 |

| Products (crude steel, aluminum rolled products, copper rolled products) | Million t | 6.3 | 7.2 | 6.7 |

| CO2 emission intensity from energy use | t-CO2 / t-product | 2.4 | 2.2 | 2.3 |

Breakdown of Greenhouse Gas Emissions (Unit: Thousand t-CO2)

| Category | Fiscal 2020 | Fiscal 2021 | Fiscal 2022 | |

|---|---|---|---|---|

| Energy-derived CO2 emissions (Scope 1) | 14,591 | 15,292 | 14,687 | |

| Non-energy-derived CO2 emissions | 498 | 568 | 887 | |

| Methane (CH4) | 5 | 6 | 5 | |

| Nitrous oxide (N2O) | 50 | 7 | 5 | |

| Hydrofluorocarbons (HFC) | - | - | - | |

| Perfluorocarbons (PFC) | - | - | - | |

| Sulfur hexafluoride (SF6) | 18 | 18 | 16 | |

| Nitrogen trifluoride (NF3) | - | - | - | |

| Total* for Non-energy-derived CO2 emissions and greenhouse gases other than CO2 |

571 | 598 | 913 | |

Other Indirect Emissions in the Supply Chain (Scope 3) (Unit: Thousand t-CO2)

| Category | Fiscal 2020 | Fiscal 2021 | Fiscal 2022 | Calculation Method |

|---|---|---|---|---|

| 1 Purchased goods and services |

5,5471 | 6,5301 | 5,888✓ | The Company’s usage of main raw materials (iron ore, coking coal, purchased coke, aluminum, copper and titanium) multiplied by CO2 emission factors |

| 2 Capital goods | 262 | 113 | 144 | Capital investment cost multiplied by CO2 emission factors |

| 3 Fuel- and energy-related activities not included in Scope 1 or Scope 2 |

3171 | 3051 | 338 | Annual consumption of electricity, steam, fuel, etc., multiplied by CO2 emission factors |

| 4 Upstream transportation and distribution |

180 | 217 | 225 | Calculated using the calculation method for energy-derived CO2 emissions related to freight transportation by shippers as stipulated in the Act on Rationalizing Energy Use |

| 5 Waste generated in operations |

30 | 30 | 30 | The amount of waste for each type multiplied by CO2 emission factors |

| 6 Business travel | 2 | 1 | 1 | Number of employees multiplied by CO2 emission factors |

| 7 Employee commuting | 5 | 5 | 5 | Number of employees multiplied by CO2 emission factors |

| 10 Processing of sold products |

2,4451 | 2,7051 | 2,563 | Calculated by multiplying the production volume of main steel products by CO2 emission factors associated with processing each type of steel product. |

| 11 Use of sold products | 36,985 | 21,478 | 17,696 | Lifetime emissions for the main machinery products sold by Kobe Steel (energy used during use: electricity) are calculated based on units sold, expected average life, average power consumption, and CO2 emission factors for electricity |

| 12 End-of-life treatment of sold products |

56 | 63 | 60 | Calculated by multiplying CO2 emission factors by the production volume of crude steel, aluminum, and copper products |

| Total2 | 45,8291 | 31,4471 | 26,950 |

In May 2021, the Kobelco Group announced, in its Medium-Term Management Plan (Fiscal 2021–2023), that it would take on the challenge of realizing carbon neutrality by 2050 and aim to increase corporate value through this transition. The Kobelco Group has set targets for 2030 and a vision for 2050 from two angles: (1) reducing CO2 emissions in the Group’s own production processes, and (2) contributing to the reduction of CO2 emissions through the Group’s distinctive technologies, products, and services.

The Group has a variety of products and services that contribute to CO2 reduction. By expanding sales of these, we will contribute to the reduction of CO2 during use.

Other Major Technologies, Products, and Services That Contribute to CO2 Reductions

| Technologies, Products, and Services | CO2 Reduction Concept | |

|---|---|---|

| Automotive/transportation field | Fuel-cell separator materials, titanium for aircraft components | Improvement of fuel economy by reducing weight of automobiles and transportation equipment, effects of replacing gasoline-powered automobiles for next-generation vehicles |

| Hydrogen utilization field | High-purity Hydrogen Oxygen Generator (HHOG) | Effects of reducing fossil resource consumption through hydrogen utilization |

| Power generation field | Conversion of sludge to fuel and its utilization at coal-fired thermal power plants (planned) | Reducing fossil resource use through the use of resources that contribute to carbon neutrality |

| Initiatives for Implementation |

Long-Term Policies | Medium-Term Targets | Fiscal 2022 Results Self-Assessment 〇:Progressing as planned △:Issues remain ×:Plan not achieved |

|

|---|---|---|---|---|

| Measures against global warming | Contribute to preventing global warming by promoting energy conservation and CO2 reduction in all business activities <Target for 2030> Reduce CO2 emissions from production processes by 30–40% (compared with fiscal 2013) <Vision for 2050> Taking on the challenge of achieving carbon neutrality |

Promote mediumto long-term technological development based on the roadmap and continue working on energy conservation initiatives, in order to achieve the targets for 2030 and vision for 2050 |

Implement initiatives and reviews following the Roadmap toward Carbon Neutrality in the Ironmaking Process and Power Generation Business. |

〇 |

| Contributing to the environment through technologies, products, and services | Create environmentally sustainable products and new businesses with due consideration of the environment in all technological and product development <Target for 2030> Contribution to CO2 reduction: 61 million tons (including at least 45 million tons of MIDREX🄬) <Vision for 2050> Contribution to CO2 reduction: 100 million tons or more |

Contribute to the creation of a lowcarbon society through the efforts of the entire Kobelco Group by working on issues related to the environment and energy fields, such as weight reduction of transportation vehicles, the creation of a hydrogenbased society, and the diversification of power sources |

FY2022 Results: 58.91 Mt contribution to reduction of CO2 emissions |

〇 |

As a member of the Global CCS Institute and the Carbon Recycling Fund Institute, we actively acquire the latest information on Carbon Capture, Utilization, and Storage (CCUS) technology and work on technological development and research on CO2 separation, capture, recycling, and sequestration for future practical use.

| Climate-Related Organizations to Which We Belong | Description |

|---|---|

| Global CCS Institute | The Global CCS Institute is an international think tank whose mission is to accelerate the deployment of Carbon Capture and Storage (CCS), a vital technology to tackle climate change and deliver climate neutrality. The institute is headquartered in Melbourne, Australia, with offices in Tokyo, Washington, D.C., Brussels, Beijing, and London. |

| Carbon Recycling Fund Institute | The Carbon Recycling Fund Institute aims to address the global warming issue and improve energy access throughout the world. The institute promotes innovation in carbon recycling by public relations and sponsoring research and development in the field. |

In addition, each of the following industry groups to which the Kobelco Group belongs have formulated actions plans for carbon neutrality. Our Group will contribute to the achievement of the targets set out in the action plans of each industry group to which we belong by pursuing energy savings and CO2 reduction in production processes.

| Industry Groups | Fiscal 2030 Industry Targets for Reducing CO2 Emissions from Production Processes in the Carbon Neutrality Action Plan |

|---|---|

| The Japan Iron and Steel Federation | 30% reduction compared to fiscal 2013 |

| Japan Aluminium Association | 31% reduction compared to fiscal 2013 |

| Japan Copper and Brass Association | 33% reduction compared to fiscal 2013 |

| The Japan Society of Industrial Machinery Manufacturers | 10% reduction compared to fiscal 2013 |

| Japan Construction Equipment Manufacturers Association | 17% reduction compared to fiscal 2013 (energy intensity) |

In order to respond to climate change in a consistent manner, Kobe Steel has established a Groupwide governance system centered on the Sustainability Management Committee.

The Sustainability Management Committee informs and educates employees about our Group Corporate Philosophy, ESG policies, and various initiatives to ensure that employees fully understand our corporate policies concerning these matters.

We collect information not only on the policies set by the Japanese government but also on industry targets and initiatives related to our business, as well as trends in regulations in the countries where we conduct business. Such information is shared with internal stakeholders, including directors and management.

When the Kobelco Group engages in any activities that may influence the national government, local governments, industry associations, etc., all members of the Group shall report such activities to the Sustainability Management Committee in advance. The committee shall confirm whether such activities are consistent with the Group Corporate Philosophy and ESG policies. The committee shall report such activities to the Executive Council and the Board of Directors for oversight in accordance with the importance of such activities.

In addition, if the efforts of industry associations/groups are not in line with the Group Corporate Philosophy or ESG policies, Kobe Steel shall put forward its opinions to industry associations/groups and work to ensure that their initiatives are consistent with its policies.

The Steel & Aluminum Business is working to improve various facilities and operations, including switching to LED lighting at plants and replacing air compressors.

We will continue to take steps to save energy and further reduce environmental impact to achieve the industry targets set in the Carbon Neutrality Action Plan.

The Welding Business is increasing the efficiency of facilities and reducing energy loss by switching to LED lighting at business sites and systematically upgrading electric machinery for higher efficiency.

In fiscal 2022, we introduced LED lighting and updated to more efficient electric motors systematically at all locations. We will continue to take steps to save energy and further reduce environmental impact in order to achieve a low-carbon society.

In fiscal 2022, the Advanced Materials Business aimed to increase energy efficiency by increasing production efficiency and introducing high-efficiency facilities.

We will continue to take steps to save energy and further reduce environmental impact to achieve each milestone in the industry targets set in the Carbon Neutrality Action Plan.

The Machinery Business is working to improve energy efficiency by switching to LED ceiling lighting in offices and plants and improving the efficiency of other equipment.

We will continue to take steps to save energy and further reduce environmental impact to achieve the industry targets set in the Carbon Neutrality Action Plan.

| Production Facility / Company Name | Location | Examples of Initiatives |

|---|---|---|

| Kakogawa Works, Kobe Steel, Ltd. | Kakogawa, Hyogo Prefecture | Updated blast furnace pneumatic cooler |

| Moka Plant, Kobe Steel, Ltd. | Moka, Tochigi Prefecture | Switched a portion of plant lighting to LED lighting |

| Chofu Works, Kobe Steel, Ltd. | Shimonoseki, Yamaguchi Prefecture | Switched heat sources at certain buildings at plants Stopped use of cooling fans by improving operations |

| Daian Works, Kobe Steel, Ltd. | Inabe, Mie Prefecture | Switched a portion of plant lighting to LED lighting |

| Ibaraki Plant, Kobe Steel, Ltd. | Ibaraki, Osaka Prefecture | Switched a portion of plant lighting to LED lighting Upgraded heating, ventilation, and air-conditioning (HVAC) |

| Saijo Plant, Kobe Steel, Ltd. | Higashihiroshima, Hiroshima Prefecture | Upgraded dust collectors Upgraded transformer |

| Fukuchiyama Plant, Kobe Steel, Ltd. | Fukuchiyama, Kyoto Prefecture | Switched a portion of plant lighting to LED lighting Reduced load on electrical machinery through process improvements Stopped use of cooling fan after process improvement |

| Fujisawa Plant, Kobe Steel, Ltd. | Fujisawa, Kanagawa Prefecture | Switched electric motors to inverters Linked production lines |

| Takasago Works, Kobe Steel, Ltd. | Takasago, Hyogo Prefecture | Switched a portion of plant lighting to LED lighting Updated transformers to high-efficiency models |

| Kobe Corporate Research Laboratories, Kobe Steel, Ltd. | Kobe, Hyogo Prefecture | Upgraded heating, ventilation, and air-conditioning (HVAC) Switched a portion of lighting to LED lighting |

| Amagasaki Works, Shinko Wire Company, Ltd. | Amagasaki, Hyogo Prefecture | Upgraded heating, ventilation, and air-conditioning (HVAC) Improved insulation performance of furnaces |

| Onoe Works, Shinko Wire Company, Ltd. | Kakogawa, Hyogo Prefecture | Switched a portion of plant lighting to LED lighting Upgraded transformer Switched electric motors to inverters |

| Nishikinohama Works, Shinko Wire Company, Ltd. | Kaizuka, Osaka Prefecture | Switched a portion of ceiling lighting to LED lighting |

| Koshuha-Foundry Co., Ltd. | Hachinohe, Aomori Prefecture | Switched to high efficiency compressor |

| Shinko Aluminum Wire Co., Ltd | Sakai, Osaka Prefecture | Switched a portion of plant lighting to LED lighting |

| Shinko Leadmikk Co., Ltd | Kitakyushu, Fukuoka Prefecture | Upgraded heating, ventilation, and air-conditioning (HVAC) |

| Shinko Industrial Co., Ltd. | Kurayoshi, Tottori Prefecture | Switched a portion of lighting to LED lighting |

| Hanshin Yosetsu Kizai Co., Ltd. | Okayama, Okayama Prefecture | Switched a portion of lighting to LED lighting |

| Harima Plant, Kobelco Compressors Corporation | Kakogun, Hyogo Prefecture | Switched a portion of office and plant lighting to LED lighting |

| Shinko Engineering Co., Ltd. | Ogaki, Gifu Prefecture | Repaired air leaks |

| Harima Plant, Kobelco Eco-Solutions Co., Ltd. | Kakogawa, Hyogo Prefecture | Reduced the number of compressors Switched a portion of lighting to LED lighting |

| Kobelco Power Kobe Inc. | Kobe, Hyogo Prefecture | Reduced driving steam Reduced fan power |

| Kobelco Power Kobe No.2 Inc. | Kobe, Hyogo Prefecture | Reduced fan power |

| Hiroshima Factory, Kobelco Construction Machinery Co., Ltd. | Hiroshima, Hiroshima Prefecture | Reduced electrical power of compressors Switched to electrical coating pumps |

| Okubo Factory, Kobelco Construction Machinery Co., Ltd. | Akashi, Hyogo Prefecture | Reduced use of electricity and gas by updating the coating line |

| Kobelco Automotive Aluminum Rolled Products (China) Co., Ltd. | China | Switched a portion of plant lighting to LED lighting |

| Kobelco Spring Wire (Foshan) Co., Ltd. (KSW) | China | Switched a portion of plant lighting to LED lighting |

| Kobe Precision Technology Sdn. Bhd. | Malaysia | Switched a portion of plant lighting to LED lighting Upgraded air compressors Installed solar powered lighting in parking lot |

| Kobe Aluminum Automotive Products, LLC (KAAP) | United States | Switched a portion of plant lighting to LED lighting |

| Kobe Aluminum Automotive Products (China) Co., Ltd. (KAAP-C) | China | Conserved electricity by switching to high efficiency motor Switched to electric forklifts Switched HVAC to latest models Reuse of backwashing wastewater of water purifiers |

| Kobelco Aluminum Products and Extrusions, Inc. (KPEX) | United States | Switched compressors to inverters |

| Thai-Kobelco Welding Co., Ltd. (TKW) | Thailand | Repaired air leaks Switched HVAC to inverter model |

| Kobelco MIG Wire (Thailand) Co., Ltd. (KMWT) | Thailand | Repaired air leaks Switched a portion of plant lighting to LED lighting |

Kobe Steel, Ltd. has been responding to questionnaires from CDP* since fiscal 2009. Please refer to the following link for our response to 2023 Climate Change Questionnaire.

* An international NGO working on environmental issues. It sends environment-related questionnaires to companies and compiles the results to analyze and evaluate on a common scale.