As part of its environmental management policies, the Kobelco Group is committed to environmentally friendly manufacturing. We pursue this commitment on a variety of fronts—including improvements to sustainable manufacturing processes, updates to equipment, introduction of efficient state-of-the-art equipment, and introduction of pollution control equipment—to reduce environmental impact from soot and other sources. We will continue to implement these initiatives.

See below for details about our management structure.

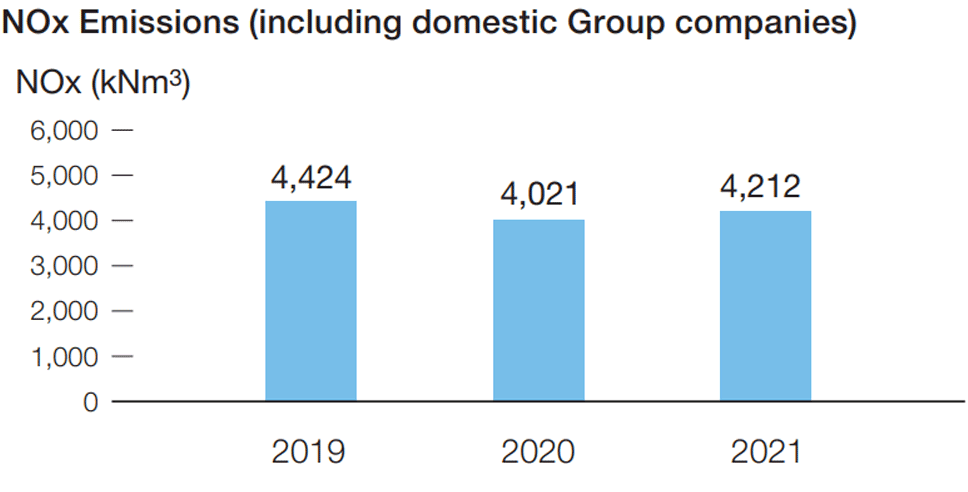

The Kobelco Group is working to control air pollutant emissions by introducing low-NOx combustion facilities along with enforcing appropriate management of exhaust gas treatment facilities and dust collectors.

The Kobelco Group has set the target in the Medium-Term Management Plan (Fiscal 2021–2023) of reducing environmental impact from soot and smoke, through meticulous operational management and facility management.

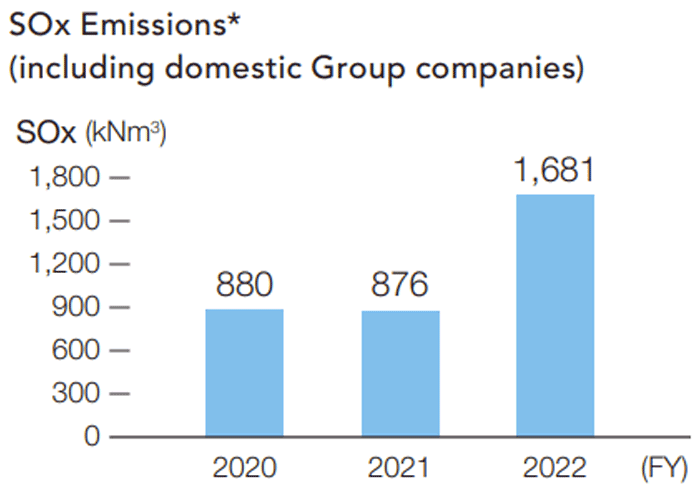

We have taken measures to limit sulfur oxide (SOx) emissions during manufacturing processes, such as conserving energy to reduce fuel consumption, using low-sulfur fuels, and switching to city gas, while also implementing exhaust-related measures, such as desulfurization. Likewise, to reduce nitrogen oxide (NOx) emissions, we have implemented low-NOx combustion technology and energysaving measures.

In fiscal 2022, we continued to control emissions by thoroughly managing soot and smoke.

* In fiscal 2022, the value was higher than usual because of maintenance on desulfurization and denitration equipment at the Kakogawa Works’ sintering plant to bypass the equipment while complying with regulation values and conventions.

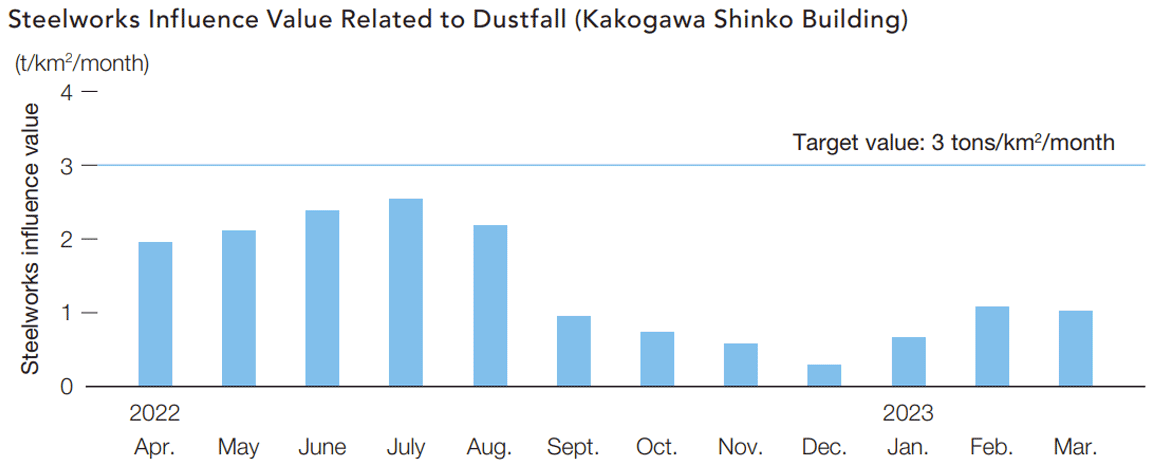

At Kakogawa Works, voluntary targets for dustfall in three neighboring locations have been set at 3.0 tons/km2 / month or less. In fiscal 2022, we achieved our target values in all months by steadily implementing existing initiatives and regularly cleaning dust prevention nets at site boundaries.

We established the Kobelco Group Policy on Controlling Hazardous Chemical Substances to ensure the appropriate handling of chemical substances from procurement to manufacturing and quality control.

We comply with all domestic laws and regulations concerning the handling of chemical substances and implement the following actions:

In addition to accurately assessing the use, disposal, and transfer of chemical substances covered under the PRTR Law1 and Chemical Substance Control Law2, we engage in activities to limit the use and output of such substances. In addition, waste electrical equipment containing PCB and equipment using fluorocarbons are appropriately stored and managed in accordance with the Act on concerning Special Measures for Promotion of Proper Treatment of PCB Wastes3 and the Act on Rational Use and Proper Management of Fluorocarbons4, respectively.

1 Law Concerning Pollutant Release and Transfer Register (PRTR): Act on Confirmation, etc. of Release Amounts of Specific Chemical Substances in the Environment and Promotion of Improvements to the Management Thereof

2 Act on the Evaluation of Chemical Substances and Regulation of Their Manufacture, etc.

3 Act on Special Measures concerning Promotion of Proper Treatment of PCB Wastes

4 Act on Rational Use and Appropriate Management of Fluorocarbons

The targets of the Group’s Medium-Term Management Plan (Fiscal 2021–2023) are to engage in appropriate management, reduction, and substitution activities for chemical substances, as well as to take appropriate measures in compliance with the Act on concerning Special Measures for Promotion of Proper Treatment of PCB Wastes and the Act on Rational Use and Proper Management of Fluorocarbons.

In fiscal 2022, we thoroughly investigated equipment containing low-concentration PCB currently inuse and outsourced processing for some following our disposal plan.

Regarding the Act on Rational Use and Proper Management of Fluorocarbons, we confirmed compliance through audits and other means.

| Fiscal 2020 | Fiscal 2021 | Fiscal 2022 | |

|---|---|---|---|

| Substances subject to reporting | 46 | 46 | 46 |

| Air emissions | 470t | 429t | 358t |

| Releases to public water areas | 57t | 63t | 48t |

| Drainage | 0.3t | 0.5t | 0.5t |

| Transfers outside the premises (waste) | 588t | 625t | 543t |

Note: The information above covers 99% of the Kobelco Group’s release and transfer of chemical substances in Japan.

(Unit: t/year)

| Fiscal 2020 | Fiscal 2021 | Fiscal 2022 | ||

|---|---|---|---|---|

| Volatile organic compounds (VOCs) | 469 | 428 | 357 | |

| Other hazardous substances | Lead | 0 | 0 | 0 |

| Manganese and its compounds | 0.1 | 0.1 | 0.3 | |

Notes: 1. Calculated for VOCs relevant to the KOBELCO Group, out of those specified as Class 1 Designated Chemical Substances in Appended Table 1 of the Ordinance for Enforcement of the Law Concerning Pollutant Release and Transfer Register

2. The information above covers 99% of the environmental impact of the Kobelco Group in Japan.

| Production Facility / Company Name | Location | Activities |

|---|---|---|

| Kobelco Wire Company, Ltd. | Izumisano, Osaka Prefecture | Change of floor coating from oil-based to water-based |

| Shinko Aluminum Wire Co., Ltd. | Sakai, Osaka Prefecture | Further shortened duration of time when the lid is left open for the degreasing cleaning tank |

For our water pollution measures, please see below