-

Distinctive Products & Technologies

- Steel & Aluminum

- Advanced Materials

- Welding

- Aluminum & Copper

- Machinery

- Engineering

- Construction Machinery

Wire Rod for Automotive Engine Valve Spring

Found in one out of every two cars worldwide!

Engine valve springs must withstand thousands of expansions and compressions per minute. They require an extremely high level of quality. Kobe Steel’s wire rod products are the brand of choice, with a 50 percent share of the world market.

High-Strength Steel Sheet

The world’s strongest steel!

Kobe Steel’s high-strength steel sheet is primarily used in auto frame parts and contributes to lighter vehicles. In particular, we are a leading manufacturer for development and commercialization of ultra high-strength steel sheet.

Aluminum Sheet and Coils for Automotive Closure Panels

50% market share in Japan!

Due to increased demand for lighter cars, the use of aluminum for engine hoods and other applications is increasing. Kobe Steel has capitalized on expertise and engineering capabilities amassed over many years to capture about 50 percent of the market in Japan.

Aluminum Bottle Can Stock

70% market share in Japan!

Kobe Steel holds a more than 30-percent market share for aluminum beverage can stock in Japan. Furthermore, Kobe Steel holds an approximately 70-percent share for aluminum bottle can stock, which requires complex processing.

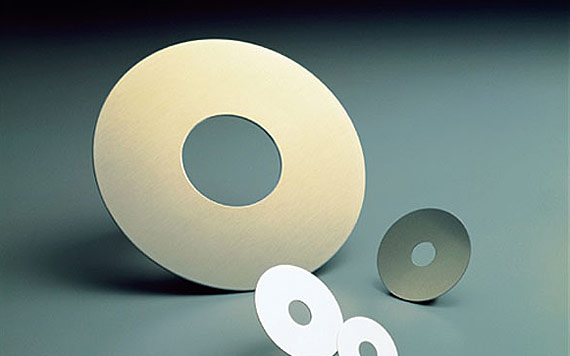

Aluminum Disks

60% share of world market!

Aluminum disks are used as substrate materials for hard disk drives for desk top computers and data centers,which require a high level of quality. Kobe Steel is the leading manufacturer of aluminum disks,holding approximately 60 percent of the world market share.

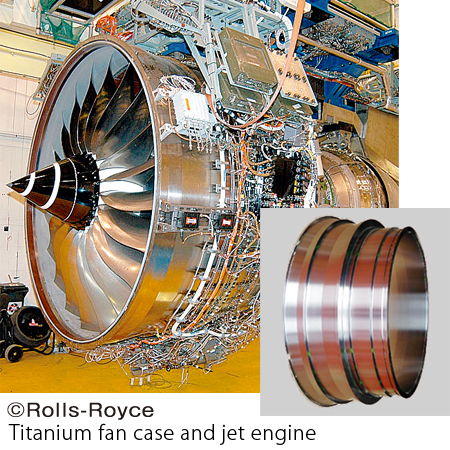

Titanium for Aircraft Engine Components

Titanium pioneer!

Titanium is an important material for components that cover the rotating parts of engines, form an airflow path, and prevent shattering during engine failure. Kobe Steel has been delivering fan case components for aircraft engines for over 30 years, meeting the demands of engine makers around the world.

Crankshafts

40% share of world market!

Crankshafts are a core ship part, transmitting power from a ship's engine to its propellers. Kobe Steel holds 40 percent of the world market share for built-up and solid crankshafts, garnering high praise for dimensional precision at the micro level.

Aluminum Forgings for Automotive Suspensions

Top market share in Japan!

Weight reduction needs have led to higher use of aluminum in suspension systems. Kobe Steel has the leading market share in Japan for aluminum forgings, which are over 40 percent lighter than conventional steel forgings.

Aluminum Shapes for Rolling Stock

Top market share in Japan!

Aluminum shapes are used in the bodies of rolling stock.Kobe Steel offers various shapes to meet customers’need for weight savings and is Japan’s top supplier of shapes for rolling stock.Recently, our aluminum shapes have been adopted in the UK.

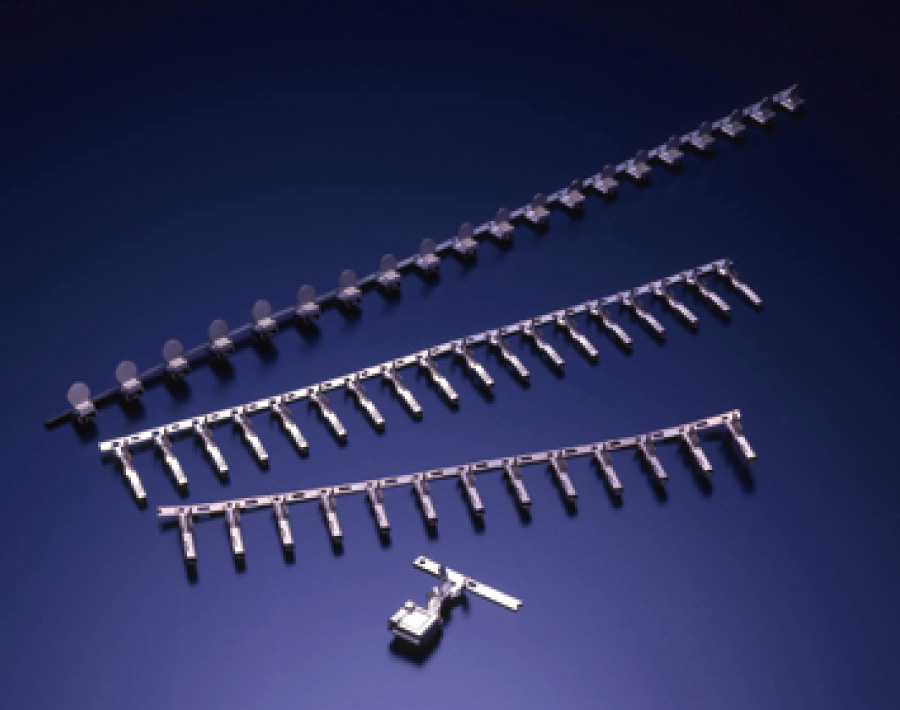

Copper Alloys and Plating for Automotive Terminals and Connectors

Top market share in Japan!

Copper alloys for automotive terminals and connectors are utilized in the wire harnesses often referred to as the nerves of an automobile. With about 30 percent of the market, Kobe Steel boasts the top share for such alloys in Japan. Our CAC®5 and CAC®60 alloys contribute to increased miniaturization and improved performance through new reflow plating offering unprecedentedly low insertion force and high contact reliability.

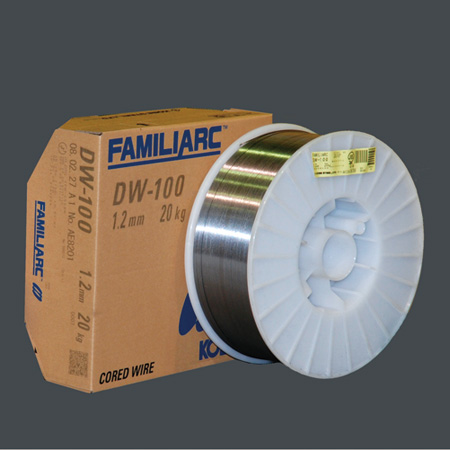

Flux-Cored Wires

Greatly contributing to reduced costs!

Kobe Steel produces welding materials with high work efficiency for a wide variety of industries, including shipbuilding, structural steel and bridge construction. These materials greatly decrease welding man hours, greatly increase welding efficiency and help create more beautiful bead appearance.

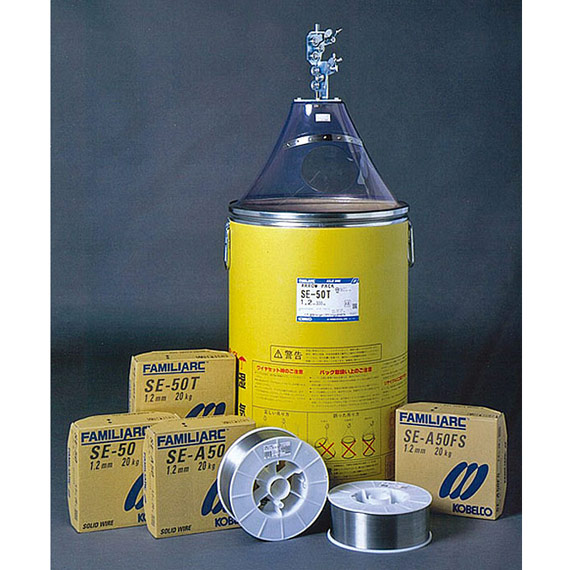

Non-Copper Coated Solid Wires (SE wire series)

Reduced environmental impact!

Produced using a unique wire surface treatment technology, non-copper coated solid wires offer groundbreaking feed capability and outstanding arc stability. These wires also reduce environmental impact, removing the need for copper plating treatment during manufacturing of the welding wire.

Welding Materials for Low-Alloy Steel

Top market share worldwide!

Increasingly sophisticated high-strength and low-alloy, heat-resistant steel is being utilized in recent years in high-temperature, high-pressure applications such as oil refining reactors and thermal power boilers. We have developed welding materials specially designed to meet these needs.

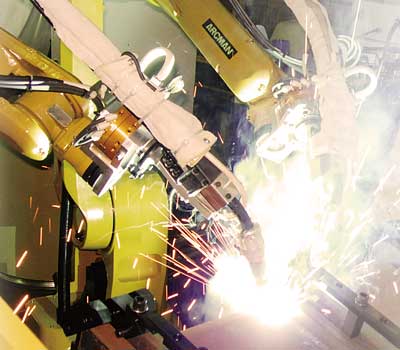

ARCMAN™-GS

Increased application of robotic welding!

The ARCMAN™ welding robot series is used in a wide range of plate welding fields, such as for structural steel and construction machinery. The GS model features internalized components such as torches and cables, making welding robots more viable in narrow spaces. It also allows for tandem welding.

REGARC™-equipped Structural Steel Welding Systems

Reduced costs and improved quality!

The REGARC™ is a groundbreaking welding process technology that can significantly reduce spatter and fumes, even with a high current, using CO2 arc welding. REGARC™-equipped structural steel welding systems achieve high-efficiency and high-quality welding with low spatter.

Nonstandard Screw Compressors

50% of market share, worldwide!

Compared with other types of compressors, screw compressors offer high compression ratios and efficiency, as well as high energy savings through excellent response to load fluctuations. Kobe Steel manufactured the first screw compressor in Japan in 1956 and has been supplying compressors to large plants ever since. Kobe Steel holds 50 percent of the world market share.

Emeraude Standard Compressors

One of the leading market shares in Japan!

With numerous industry-first features, Kobe Steel’s standard compressors boast unparalleled specs and energy efficiency. The Emeraude is our most representative standard compressor model, possessing one of the leading market shares in Japan.

Microbinary Generators

Compact and efficient!

We supply compact, highly efficient microbinary power generation systems, capable of generating electricity from heat sources of around 100°C. These generators are being adopted for effective utilization of unused heat sources, such as factory waste heat and hot spring waters, as well as for generation from wood biomass.

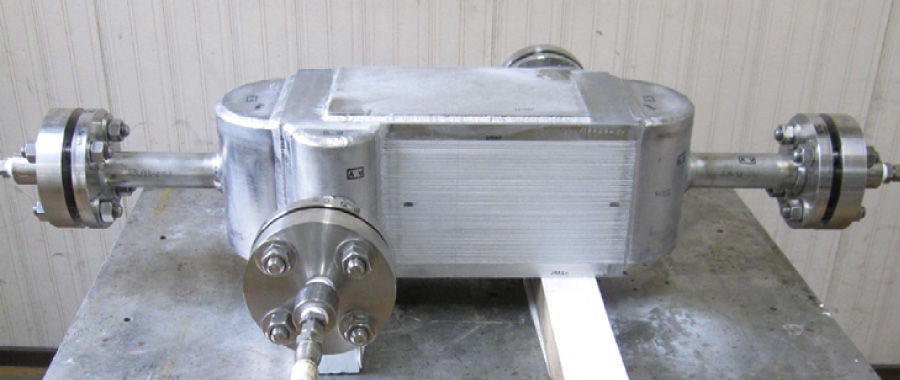

Microchannel heat exchangers (DCHE)

Leading results in Japan!

Through processing, lamination and diffusion bonding ofstainless steel and other plates, we create high-strengthheat exchangers with heat transfers surface areas of1000 m2/m3 or more by volume.

Compact and with exceptional thermal conductivity,these heat exchangers are used in applications such ashydrogenfueling stations and marine facilities.Rubber Mixers

40% share of world market!

Kobe Steel is a leading manufacturer of rubber mixers, which are indispensable for the production of tires and rubber products.Our rubber mixers account for 40 percent of the global market share. Our state-ofthe-art technology, which offers exceptional mixing as well as high productivity and energy efficiency, has garnered praise worldwide.

MIDREX® Process

World’s most widely used DR process!

Developed by Midrex Technologies, Inc., a wholly owned subsidiary of Kobe Steel, the MIDREX® Process utilizes natural gas to make direct reduced iron. As the world’s leading direct reduction process, it is used in over 70 plants worldwide, particularly in the Middle East.

Water Treatment Facilities

Full lineup!

A leading manufacturer in the field of water treatment, Kobelco Eco-Solutions offers a full lineup of water treatment products, including water and sewage treatment facilities, industrial water and wastewater treatment facilities, sludge treatment facilities and pure/ultra-pure water production facilities. Kobelco Eco-Solutions is also a supplier of pure and ultrapure water and is expanding sales in this area.

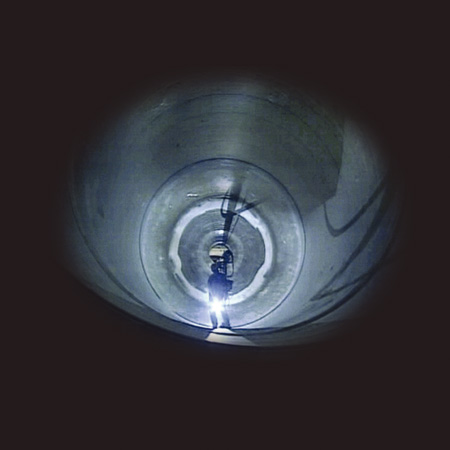

Sewage Biogas City Gas Pipe Injection Facility

Effective utilization of biogases!

Together with local authorities and gas suppliers, Kobelco Eco-Solutions developed a city gas facility capable of refining gas from sewage sludge to the same quality as city gas. In October 2010, Kobelco Eco-Solutions began injecting biogas into city gas pipes. Biogas is a combustible gas produced from methane fermentation of biomass solids such as sewage and food scraps. A carbon-neutral energy source, biogas has aroused significant interest for its potential to reduce dependence on fossil fuels.

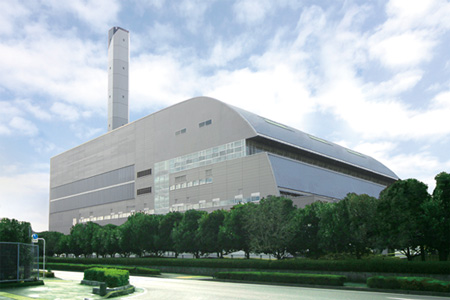

Fluidized-Bed Gasification and Melting Furnaces

Environmentally friendly melting furnaces!

These furnaces offer environment-friendly treatment, utilizing the energy found in waste to carry out everything from incineration to ash melting (reduction/slagging), thus reducing both landfill and CO2.

PCB Detoxification Facilities

Safe PCB detoxification!

Metallic sodium dispersion (SP process), solvent extraction decomposition (SED process) and plasma melting decomposition methods (which can simultaneously treat a wide variety of PCB wastes) are utilized at PCB waste treatment facilities in locations throughout the country.

Hybrid Hydraulic Excavators

The world’s first hybrid hydraulic excavator with a lithium-ion battery!

Having begun R&D in 1999, Kobelco Construction Machinery created the world’s first hybrid hydraulic excavator in 2006. It later came out with 8-ton and 20-ton class models, and in November 2016 released the SK200H, a state-of-the-art 20-ton class hybrid hydraulic excavator that makes full use of a high-capacity, lithium-ion battery, which is an industry first. With fuel consumption up to 19 percent lower, the excavator can handle workloads that are 10 percent higher. The SK200H is the pride of Kobelco and the flagship machine in its product lineup. Kobelco is committed to providing higher product value to customers based on the concept of “Power Meets Efficiency.”

TK-G Series Telescopic Boom Crawler Cranes

High transport performance

Kobelco Construction Machinery’s TK Series of Telescopic Boom Crawler Cranes have garnered strong praise from customers for many years. In June 2017 a new model, the TK-G Series, was released for sale in Japan. The G Series is durable enough for hard foundation construction work, features a compact layout for superior operability, and the ability to hoist to tall heights—but with a transport width of less than three meters.