February 16, 2021

Kobe Steel, Ltd.

Kobe Steel, Ltd. announces that it has successfully demonstrated the technology that can reduce a significant amount of CO2 emissions from blast furnace operations, combining the technologies of Midrex*1) in the engineering business and the blast furnace operation technology in the iron and steel business. This achievement is a result of the integrated efforts of the Kobe Steel Group (also known as the KOBELCO Group) leveraging its diverse businesses. The demonstration test was conducted for a month at a large blast furnace (4,844 m3) of the Kakogawa Works in Hyogo Prefecture, Japan in October 2020.

The quantity of CO2 emissions from the blast furnace is determined by the reducing agent rate (RAR)*2) or the quantity of carbon fuel used in blast furnace ironmaking. In the demonstration test, it was verified that RAR could be stably reduced from 518 kg/tHM (ton hot metal) to 415 kg/tHM by charging a large amount of hot briquetted iron (HBI)*3) produced by the MIDREX® Process*4). The results indicate that this technology can reduce CO2 emissions by approximately 20% compared to a conventional method*5).

In addition, the world's lowest level of coke rate (239 kg/tHM) has been achieved in the demonstration test of this technology. The company sees it as a promising solution that could become readily available in the near future at a lower additional cost compared to other CO2 reduction measures.

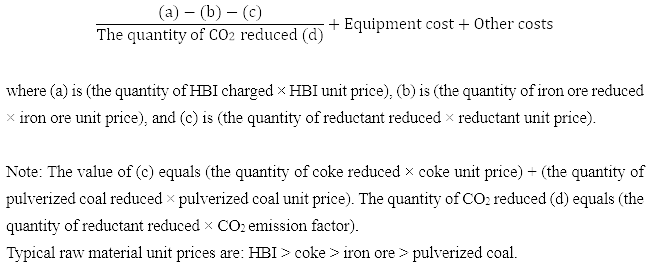

CO2 reduction cost using this technology is calculated as follows:

The key technologies utilized for this achievement are:

All of these technologies are developed by the KOBELCO Group as generic solution technologies applicable to various blast furnaces.

We will keep improving this CO2 reduction solution technology while further reducing CO2 emissions and achieving lower costs for CO2 reduction. Beyond our own efforts to reduce emissions from our facilities, we will strive to contribute to the acceleration of CO2 reduction through introducing this solution to blast furnaces around the world.

In addition, we believe that the success of the demonstration test on an actual blast furnace has made a significant step forward in providing low CO2 steel products to customers. As moving forward with our environmental efforts on the scale of the whole supply chain, we will establish production and sales systems and define the terms and conditions for sales so that we can provide customers with low CO2 steel products that offer new added value.

The mission of the KOBELCO Group is to develop and establish technologies that can reduce CO2 emissions as quickly as possible and at the lowest possible cost in order to proceed with the initiatives to create a green society toward the goal of achieving carbon neutrality in 2050 as declared by the Japanese government.

The KOBELCO Group has always strived to and will continue to provide solutions to the needs of society by making the best use of the talents of our employees and our technologies with a view to realizing a world in which people, now and in the future, can fulfill their hopes and dreams while enjoying safe, secure, and prosperous lives.

*1) Midrex Technologies, Inc. is a Kobe Steel’s wholly owned subsidiary in the U.S.

*2) Reducing agent rate (RAR) = coke rate (determined by the quantity of coke used in blast furnace) + pulverized coal rate (determined by the quantity of pulverized coal injected into blast furnace). Coke is carbon fuel made from coal.

*3) Hot briquetted iron (HBI) is direct reduced iron (DRI) in a briquetted form. Since hot DRI is not suitable for long-distance transportation, it is pressed into a compact solid (briquette) upon being discharged from the reduction furnace.

*4) The MIDREX® Process is the leading direct reduced iron (DRI) making process, which produces approximately 80% of the world’s direct reduced iron with natural gas (approximately 60% of the world’s direct reduced iron at large). The MIDREX® Process uses natural gas as the reductant and pellets made of iron ore as the source of iron to make DRI through the reduction process in the shaft furnace. In comparison to the blast furnace method, the MIDREX® Process can reduce CO2 emissions by 20 to 40%. There are over 90 MIDREX modules worldwide.

*5) The results are compared with fiscal 2013, which is the base year of the CO2 reduction targets set by the government and the KOBELCO Group.

(Note) The information on this web site is presented "as is." Product availability, organization, and other content may differ from the time the information was originally posted. Changes may take place without notice.